E N G IN E FUEL

6 M - 4 7

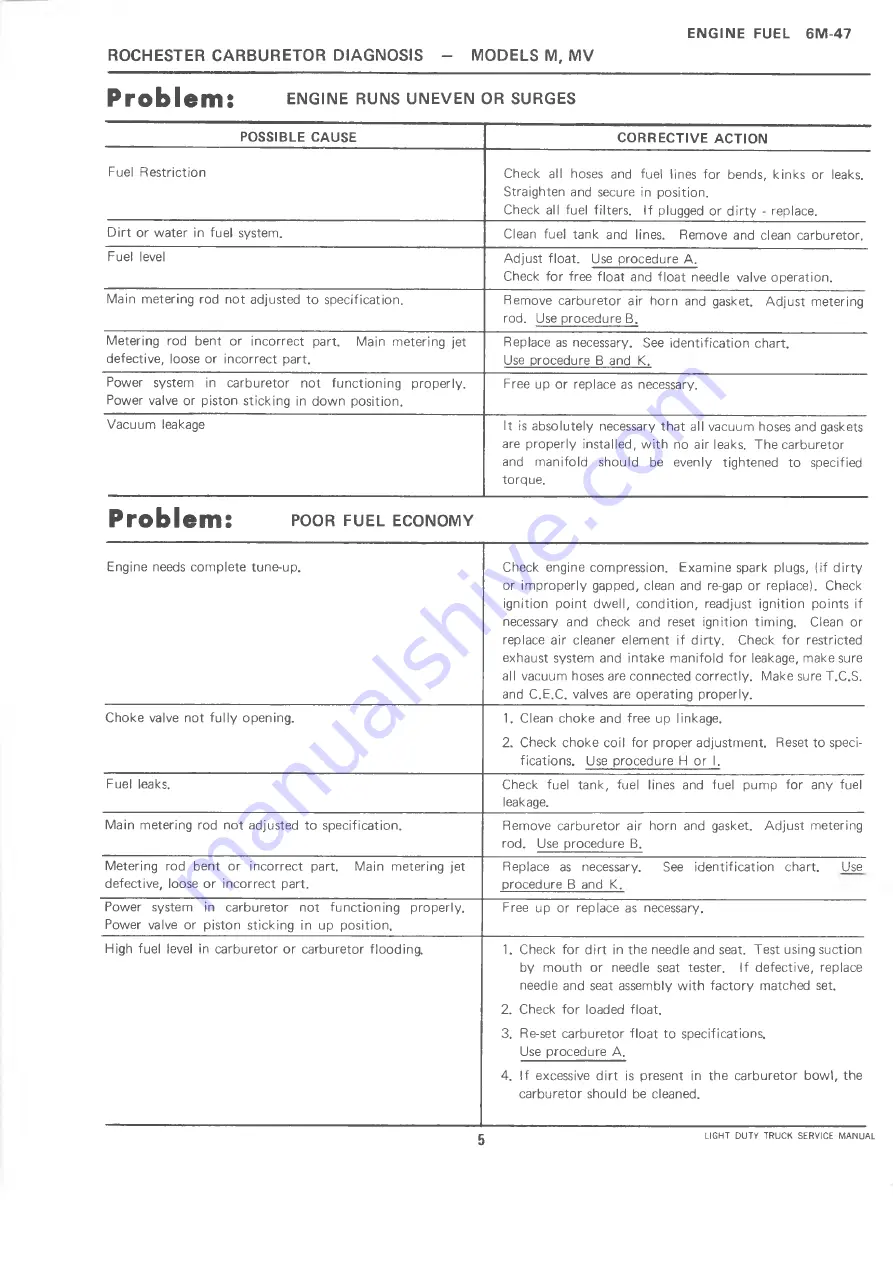

ROCHESTER CARBURETOR DIAGNOSIS

-

MODELS M, MV

Problem :

e n g i n e

r u n s

u n e v e n

o r

s u r g e s

PO SSIBLE CAUSE

C O R R E C T IV E ACTION

Fuel Restriction

Check all hoses and fuel lines for bends, kinks or leaks.

Straighten and secure in position.

Check all fuel filters. If plugged or d irty - replace.

D irt or water in fuel system.

Clean fuel tank and lines.

Remove and clean carburetor.

Fuel level

Adjust float. Use procedure A.

Check for free float and float needle valve operation.

Main metering rod not adjusted to specification.

Remove carburetor air horn and gasket. Adjust metering

rod. Use procedure B.

Metering rod bent or incorrect part.

Main metering jet

defective, loose or incorrect part.

Replace as necessary. See identification chart.

Use procedure B and K.

Power system in carburetor not functioning properly.

Power valve or piston sticking in down position.

Free up or replace as necessary.

Vacuum leakage

It is absolutely necessary that all vacuum hoses and gaskets

are properly installed, w ith no air leaks. The carburetor

and manifold should be evenly tightened to specified

torque.

Problem:

p o o r

f u e l

e c o n o m y

Engine needs complete tune-up.

Check engine compression. Examine spark plugs, (if d irty

or improperly gapped, clean and re-gap or replace). Check

ignition point dwell, condition, readjust ignition points if

necessary and check and reset ignition timing. Clean or

replace air cleaner element if d irty. Check fo r restricted

exhaust system and intake manifold fo r leakage, make sure

all vacuum hoses are connected correctly. Make sure T.C.S.

and C.E.C. valves are operating properly.

Choke valve not fu lly opening.

1. Clean choke and free up linkage.

2. Check choke coil for proper adjustment. Reset to speci

fications. Use procedure H or I.

Fuel leaks.

Check fuel tank, fuel lines and fuel pump for any fuel

leakage.

Main metering rod not adjusted to specification.

Remove carburetor air horn and gasket. Adjust metering

rod. Use procedure B.

Metering rod bent or incorrect part.

Main metering jet

defective, loose or incorrect part.

Replace as necessary.

See identification chart.

Use

procedure B and K.

Power system in carburetor not functioning properly.

Power valve or piston sticking in up position.

Free up or replace as necessary.

High fuel level in carburetor or carburetor flooding.

1. Check for d irt in the needle and seat. Test using suction

by mouth or needle seat tester.

If defective, replace

needle and seat assembly w ith factory matched set.

2. Check fo r loaded float.

3. Re-set carburetor float to specifications.

Use procedure A.

4. If excessive d irt is present in the carburetor bowl, the

carburetor should be cleaned.

5

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......