HEATER A N D AIR C O N D I T I O N I N G

1A-47

vacuum reduces, it indicates a leak in the system or

gauge connections; locate and repair all leaks.

Charging the System

1. Only after evacuating as above, is system ready for

charging. Note reading on sight glass of charging

cylinder. If it does not contain a sufficient amount

of refrigerant for a full charge, fill to the proper

level.

2. With High and Low Pressure Valves (1 and 2) open,

close Vacuum Control Valve (3), turn off vacuum

pump, open refrigerant control valve (4) and allow

refrigerant to enter system.

NOTE: If the charge will not transfer

completely from the station to the system,

close the high pressure valve at the gauge set,

set the air conditioning controls for cooling,

check that the engine compartment is clear of

obstructions, and start the engine. Compres

sor operation will decrease the low side

pressure in the system.

System is now charged and should be checked as

outlined below:

Checking System Operation

1. Operate system for a maximum of five minutes at

maximum cooling, high blower speed and with

engine operating at 2000 RPM (exhaust should be

vented if inside).

2. When system is stabilized, the pressure gauges on

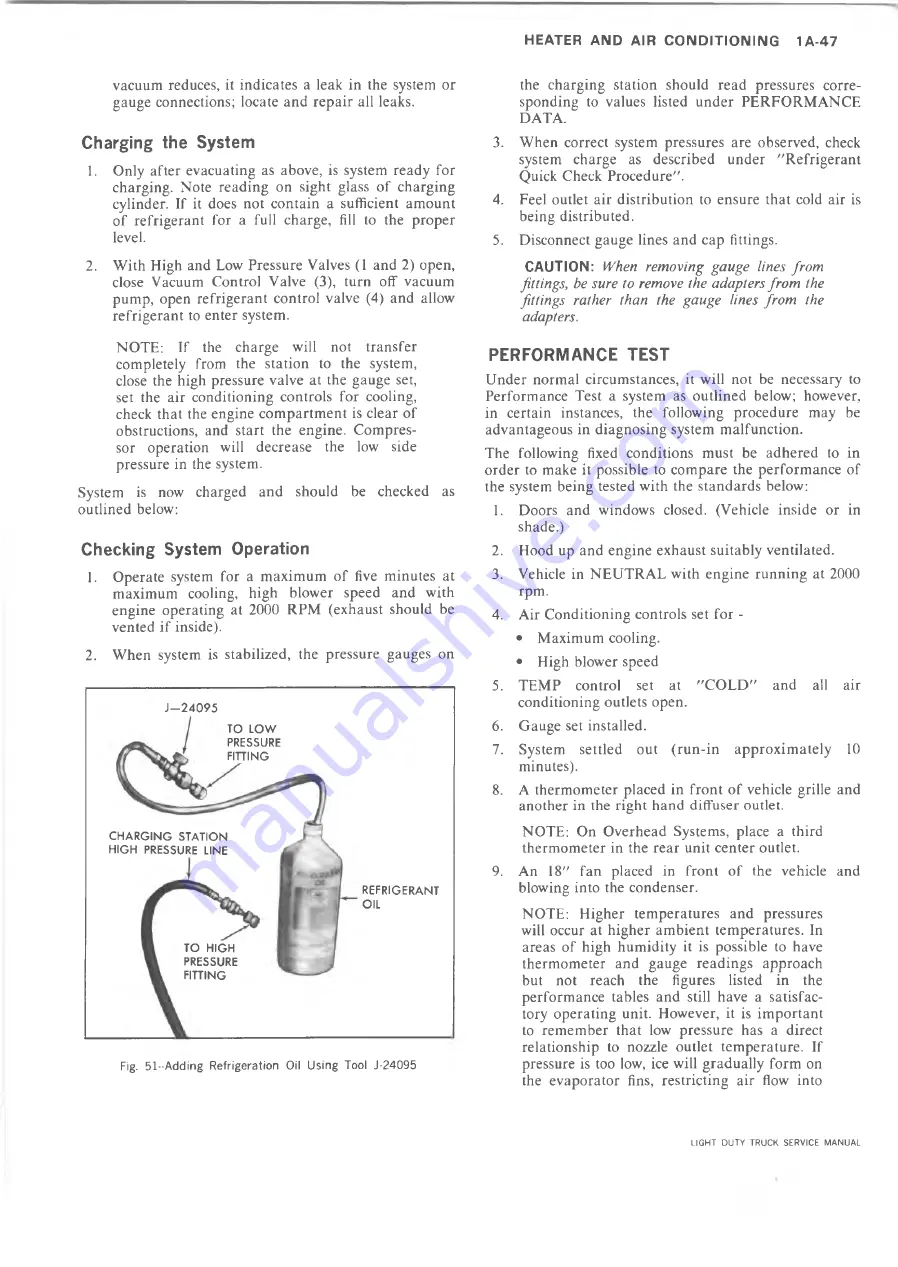

Fig. 51-Adding Refrigeration Oil Using Tool J-24095

the charging station should read pressures corre

sponding to values listed under PERFORMANCE

DATA.

3. When correct system pressures are observed, check

system charge as described under "Refrigerant

Quick Check Procedure".

4. Feel outlet air distribution to ensure that cold air is

being distributed.

5. Disconnect gauge lines and cap fittings.

CAUTIO N:

When removing gauge lines from

fittings, be sure to remove the adapters from the

fittings rather than the gauge lines from the

adapters.

PERFORMANCE TEST

Under normal circumstances, it will not be necessary to

Performance Test a system as outlined below; however,

in certain instances, the following procedure may be

advantageous in diagnosing system malfunction.

The following fixed conditions must be adhered to in

order to make it possible to compare the performance of

the system being tested with the standards below:

1. Doors and windows closed. (Vehicle inside or in

shade.)

2. Hood up and engine exhaust suitably ventilated.

3. Vehicle in NEUTRAL with engine running at 2000

rpm.

4. Air Conditioning controls set for -

• Maximum cooling.

• High blower speed

5. TEMP control set at "COLD" and all air

conditioning outlets open.

6. Gauge set installed.

7. System settled out (run-in approximately 10

minutes).

8. A thermometer placed in front of vehicle grille and

another in the right hand diffuser outlet.

NOTE: On Overhead Systems, place a third

thermometer in the rear unit center outlet.

9. An 18" fan placed in front of the vehicle and

blowing into the condenser.

NOTE: Higher temperatures and pressures

will occur at higher ambient temperatures. In

areas of high humidity it is possible to have

thermometer and gauge readings approach

but not reach the figures listed in the

performance tables and still have a satisfac

tory operating unit. However, it is important

to remember that low pressure has a direct

relationship to nozzle outlet temperature. If

pressure is too low, ice will gradually form on

the evaporator fins, restricting air flow into

J - 2 4 0 9 5

TO LOW

PRESSURE

FITTING

CHARGING STATION

HIGH PRESSURE LINE

REFRIGERANT

OIL

TO HIGH

PRESSURE

FITTING

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......