9 -3 0 STEERING

CAPTURING

STRAP

COUPLING TO

STEERING SHAFT

FLANGE BOLTS

Fig. 4 3 — F lex ib le T y p e S te e r in g C o u p lin g — M a n u a l

1. Install the flexible coupling onto the steering gear

wormshaft, aligning the flat on the shaft with the

flat in the coupling.

NOTE: Push the coupling onto the worm

shaft until the coupling reinforcement

bottoms against the end of the worm.

2. Install the special bolt into the split clamp and

torque to specifications.

NOTE: The bolt must pass through the shaft

undercut.

3. Place the steering gear into position, guiding the

flexible coupling bolts into the proper holes in the

steering shaft flange.

4. Install and tighten the steering gear to frame bolts.

5. Install the coupling to flange bolt nuts and washers

and torque to specifications. Be sure to maintain a

coupling to flange dimension of .250" to .375". The

coupling alignment pins should be centered in the

flange slots.

INTERMEDIATE STEERING SHAFTS WITH

POT

JOINT COUPLINGS

Removal (Fig. 44)

1. Remove the lower shaft flange to flexible coupling

bolts.

2. Remove upper shaft to intermediate coupling bolt.

3. Remove the steering gear to frame bolts and lower

the steering gear far enough to remove the

intermediate shaft assembly.

NOTE: It is not necessary to remove the

pitman arm from the pitman shaft.

Disassembly

1. Mark cover to shaft relationship. Pry off snap ring

and slide cover from shaft.

SPRING

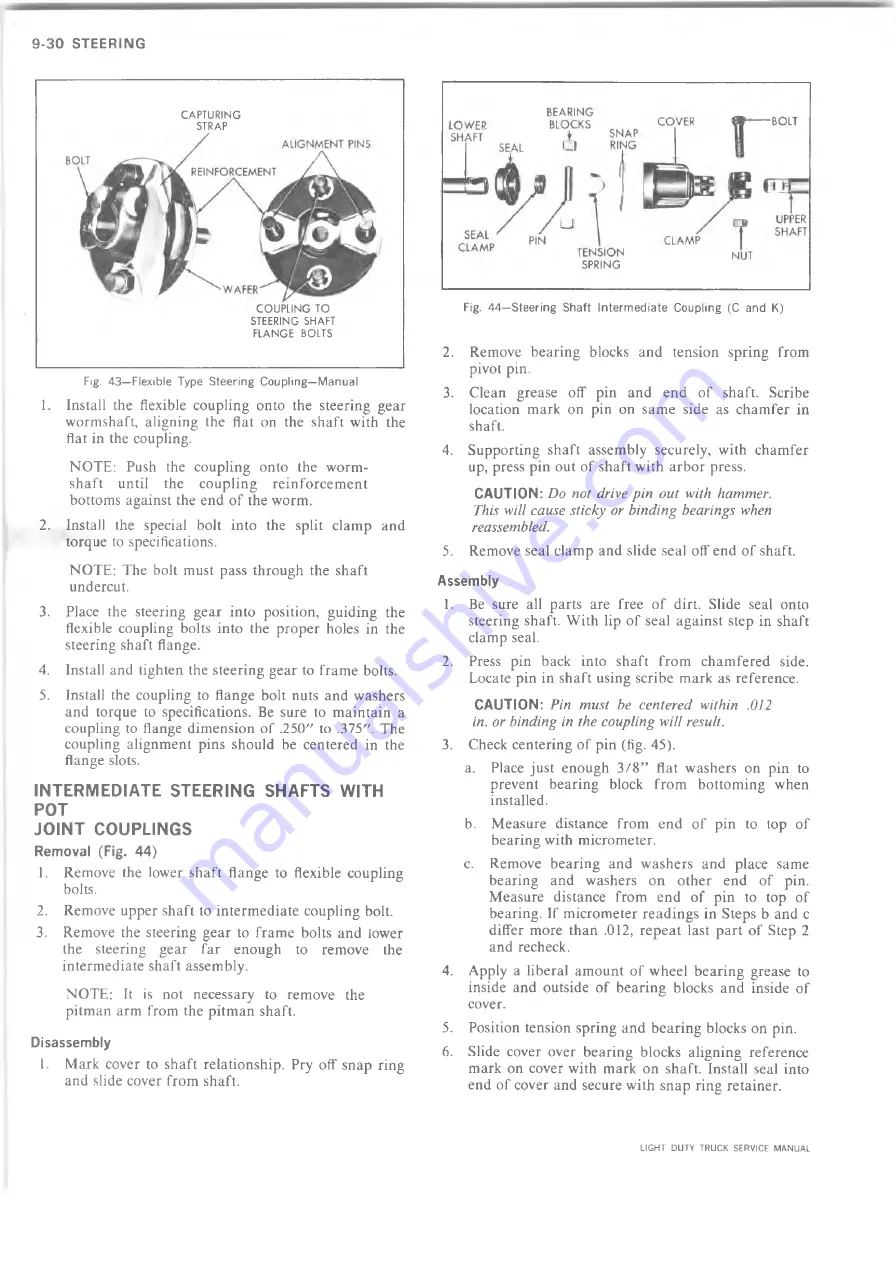

Fig. 4 4 — S te e r in g S h a ft In te r m e d ia te C o u p lin g (C a n d K )

2. Remove bearing blocks and tension spring from

pivot pin.

3. Clean grease off pin and end of shaft. Scribe

location mark on pin on same side as chamfer in

shaft.

4. Supporting shaft assembly securely, with chamfer

up, press pin out of shaft with arbor press.

CAUTIO N:

Do not drive pin out with hammer.

This will cause sticky or binding bearings when

reassembled.

5. Remove seal clamp and slide seal off end of shaft.

Assembly

1. Be sure all parts are free of dirt. Slide seal onto

steering shaft. With lip of seal against step in shaft

clamp seal.

2. Press pin back into shaft from chamfered side.

Locate pin in shaft using scribe mark as reference.

CAUTIO N:

Pin must be centered within .012

in. or binding in the coupling will result.

3. Check centering of pin (fig. 45).

a. Place just enough 3/8” flat washers on pin to

prevent bearing block from bottoming when

installed.

b. Measure distance from end of pin to top of

bearing with micrometer.

c. Remove bearing and washers and place same

bearing and washers on other end of pin.

Measure distance from end of pin to top of

bearing. If micrometer readings in Steps b and c

differ more than .012, repeat last part of Step 2

and recheck.

4. Apply a liberal amount of wheel bearing grease to

inside and outside of bearing blocks and inside of

cover.

5. Position tension spring and bearing blocks on pin.

6. Slide cover over bearing blocks aligning reference

mark on cover with mark on shaft. Install seal into

end of cover and secure with snap ring retainer.

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......