1 A-4 HEATER A N D AIR C O N D I T IO N I N G

Temperature Lever

This lever controls the positioning of the TEMPERA

TURE door in the heater distributor assembly. All

incoming "outside" air is directed around the heater core

in the COLD position on through the core in the HOT

position. The desired outlet temperature is obtained by

blending heated and unheated air according to the

setting of the temperature lever.

Heater-Def Lever

The HEATER-DEF lever controls positioning of the AIR

and DEFROSTER doors in the heater distributor

assembly. In the OFF position, no air is allowed to enter

the system. Moving the lever to the right (toward

HEATER) opens the air door with the AIR door being

fully open at the HEATER position. Incoming air is

directed to the heater outlets (with slight air bleed to the

defroster outlets). Moving the lever between HEATER

and DEF, directs increasing amounts of air to the

defroster outlets until all air is directed to the defroster

outlets in the DEF position.

Fan Control

The blower fan lever is located on the left hand side of

the control assembly. When the lever is fully down, the

blower motor is inoperative. Moving the lever upward

actuates the three speed blower motor (LOW-MED-HI).

C O M P O N E N T PART REPLACEMENT

BLOWER MOTOR

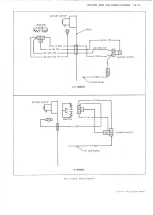

Removal (Fig. 4)

1. Disconnect battery ground cable.

G Models

- Remove the battery.

2. Disconnect the blower motor lead wire.

3. Remove the five blower motor mounting screws and

remove the motor and wheel assembly. Pry gently

on the blower flange if the sealer acts as an

adhesive.

4. Remove the blower wheel to motor shaft nut and

separate the wheel and motor assemblies.

5. To install a new motor, reverse Steps l-4 above.

NOTE: The following precautions should be

taken to assure proper installation:

a. Assemble the blower wheel to the motor with

the open end of the wheel away from the blower

motor.

b. If the motor mounting flange sealer has

hardened, or is not intact, remove the old sealer

and apply a new bead of sealer to the entire

circumference of the mounting flange.

c. Check blower operation; blower wheel should

rotate freely with no interference.

HEATER DISTRIBUTOR AND CORE

ASSEMBLY

C-K Models

Replacement (Fig. 5)

1. Disconnect the battery ground cable.

2. Disconnect the heater hoses at the core tubes and

drain engine coolant into a clean pan. Plug the core

tubes to prevent coolant spillage at removal.

Fig. 4-Blower Motor Assembly

3. Remove the nuts from the distributor duct studs

projecting into the engine compartment.

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......