6 M - 4 0 EN GINE FUEL

3. Remove clip and sensor from air cleaner.

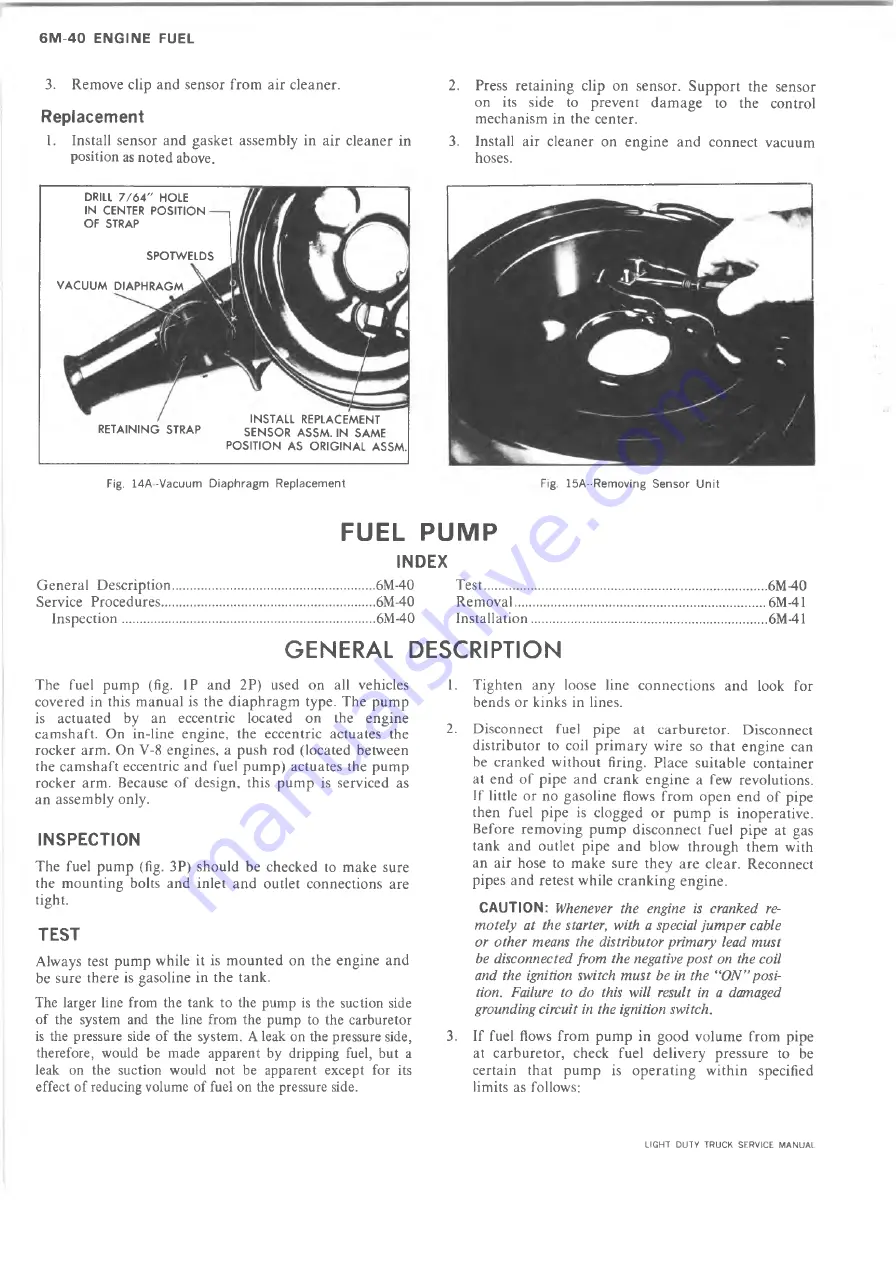

Replacement

1. Install sensor and gasket assembly in air cleaner in

position as noted above.

DRILL 7 /6 4 " HOLE

IN CENTER POSITION

OF STRAP

SPOTWELDS

VACUUM DIAPHRAGM

RETAINING STRAP

INSTALL REPLACEMENT

SENSOR ASSM. IN SAME

POSITION AS ORIGINAL ASSM.

2. Press retaining clip on sensor. Support the sensor

on its side to prevent damage to the control

mechanism in the center.

3. Install air cleaner on engine and connect vacuum

hoses.

Fig. 14A-Vacuum Diaphragm Replacement

Fig. 15A--Removing Sensor Unit

FUEL PUMP

INDEX

General Description..........................................................6M-40

Test..................................................................................6M-40

Service Procedures............................................................. 6M-40

Removal........................................................................ 6M-41

Inspection.........................................................................6M-40

Installation.................................................................... 6M-41

GENERAL DESCRIPTION

The fuel pump (fig. IP and 2P) used on all vehicles

covered in this manual is the diaphragm type. The pump

is actuated by an eccentric located on the engine

camshaft. On in-line engine, the eccentric actuates the

rocker arm. On V

-8

engines, a push rod (located between

the camshaft eccentric and fuel pump) actuates the pump

rocker arm. Because of design, this pump is serviced as

an assembly only.

INSPECTION

The fuel pump (fig. 3P) should be checked to make sure

the mounting bolts and inlet and outlet connections are

tight.

TEST

Always test pump while it is mounted on the engine and

be sure there is gasoline in the tank.

The larger line from the tank to the pump is the suction side

of the system and the line from the pump to the carburetor

is the pressure side of the system. A leak on the pressure side,

therefore, would be made apparent by dripping fuel, but a

leak on the suction would not be apparent except for its

effect of reducing volume of fuel on the pressure side.

1. Tighten any loose line connections and look for

bends or kinks in lines.

2. Disconnect fuel pipe at carburetor. Disconnect

distributor to coil primary wire so that engine can

be cranked without firing. Place suitable container

at end of pipe and crank engine a few revolutions.

If little or no gasoline flows from open end of pipe

then fuel pipe is clogged or pump is inoperative.

Before removing pump disconnect fuel pipe at gas

tank and outlet pipe and blow through them with

an air hose to make sure they are clear. Reconnect

pipes and retest while cranking engine.

CAUTION:

Whenever the engine is cranked re

motely at the starter, with a special jumper cable

or other means the distributor primary lead must

be disconnected from the negative post on the coil

and the ignition switch must be in the “O N ” posi

tion. Failure to do this will result in a damaged

grounding circuit in the ignition switch.

3. If fuel flows from pump in good volume from pipe

at carburetor, check fuel delivery pressure to be

certain that pump is operating within specified

limits as follows:

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......