6 T - 2 6 E M I S S I O N C O N T R O L S Y S T E M S

THEORY OF OPERATION

The Air Injector Reactor (A.I.R.) system (Fig. 5f) is an

exhaust emission system that is used to actually burn the

unburned portion of the exhaust gases to reduce it’s

hydrocarbon and carbon monoxide content. The system

is primarily composed of an air pump, diverter valve,

check valve(s), combustion pipe assemblies and connect

ing hoses and fittings.

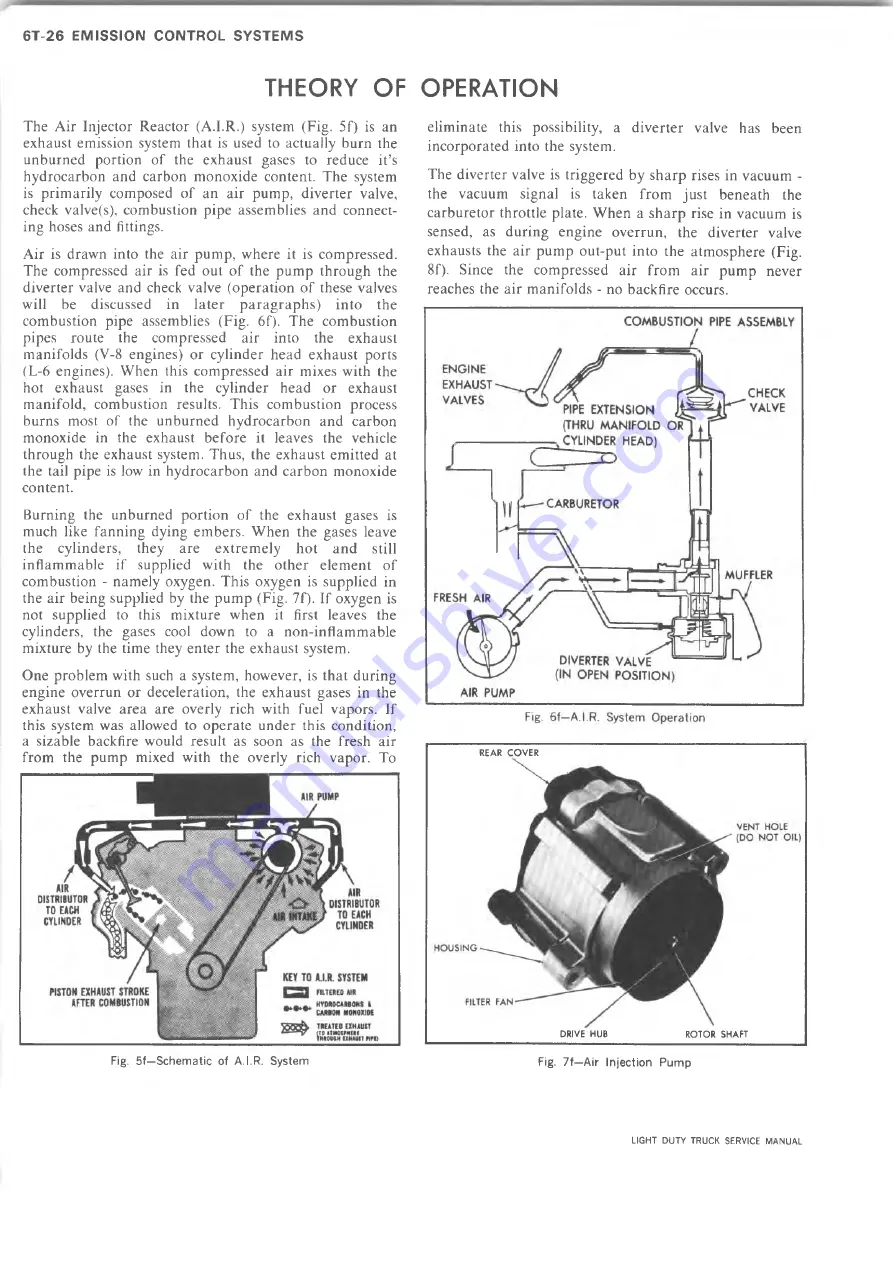

Air is drawn into the air pump, where it is compressed.

The compressed air is fed out of the pump through the

diverter valve and check valve (operation of these valves

will be discussed in later paragraphs) into the

combustion pipe assemblies (Fig.

6

f). The combustion

pipes route the compressed air into the exhaust

manifolds (V

-8

engines) or cylinder head exhaust ports

(L

-6

engines). When this compressed air mixes with the

hot exhaust gases in the cylinder head or exhaust

manifold, combustion results. This combustion process

burns most of the un burned hydrocarbon and carbon

monoxide in the exhaust before it leaves the vehicle

through the exhaust system. Thus, the exhaust emitted at

the tail pipe is low in hydrocarbon and carbon monoxide

content.

Burning the unburned portion of the exhaust gases is

much like fanning dying embers. When the gases leave

the cylinders, they are extremely hot and still

inflammable if supplied with the other element of

combustion - namely oxygen. This oxygen is supplied in

the air being supplied by the pump (Fig. 7f). If oxygen is

not supplied to this mixture when it first leaves the

cylinders, the gases cool down to a non-inflammable

mixture by the time they enter the exhaust system.

One problem with such a system, however, is that during

engine overrun or deceleration, the exhaust gases in the

exhaust valve area are overly rich with fuel vapors. If

this system was allowed to operate under this condition,

a sizable backfire would result as soon as the fresh air

from the pump mixed with the overly rich vapor. To

Fig. 5f—Schematic of A.I.R. System

eliminate this possibility, a diverter valve has been

incorporated into the system.

The diverter valve is triggered by sharp rises in vacuum -

the vacuum signal is taken from just beneath the

carburetor throttle plate. When a sharp rise in vacuum is

sensed, as during engine overrun, the diverter valve

exhausts the air pump out-put into the atmosphere (Fig.

8

f). Since the compressed air from air pump never

reaches the air manifolds - no backfire occurs.

REAR COVER

DRIVE HUB

ROTOR SHAFT

Fig. 7f—Air Injection Pump

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......