E N G I N E E L E C T R IC A L

6 Y - 9

• Note the electrolyte level. Levels that are too low or

too high may cause poor performance, as covered in

the section entitled “General Information”.

• Check for loose cable connections. Correct as

required before proceeding with tests.

Instrument Test

A number of suppliers have approved testing equipment

available. These testers have a programmed test

procedure consisting of a series of timed discharge and

charge events, requiring approximately 2 to 3 minutes,

that will determine the condition of the battery with a

high degree of accuracy. When using these testers, the

procedure recommended by the tester manufacturer

should be followed. Batteries should not be charged prior

to testing as doing so may alter the test results. If a tester

is not available for testing, the “Specific Gravity Cell

Comparison Test” may be used or an alternate method,

but with a sacrifice in testing accuracy.

NOTE: New energizers which have become

completely discharged over a relatively long

period of time, such as during vehicle

storage, should be tested by the hydrometer

method. Energizers discharged to this degree

cannot be accurately tested using equipment

requiring load capability comparison tests.

Full Charge Hydrometer Test

This test should be used only on Energizers which test

good with testing equipment or “Specific Gravity Cell

Comparison Test” but which subsequently fail in service.

• Remove the Energizer from the vehicle, and adjust

the electrolyte level as necessary, by adding

colorless, odorless, drinking water.

• Fully charge the Energizer at the Slow Charging

rate as covered in the section entitled “Charging

Procedures”.

• Measure the specific gravity of the electrolyte in

each cell and interpret as follows:

Hydrometer Reading Less Than 1.230—Full charge

hydrometer readings less than 1.230 corrected for

temperature indicate the Battery is defective and

should be replaced.

Hydrometer Readings Above 1.310—Full charge

hydrometer readings above 1.310 corrected for

temperature indicate that the cells have been

improperly filled (activation) or improperly serviced.

Poor service and short Battery life will result.

Load Test

In addition to the instrument test and full charge

hydrometer test, the following load test may also be

performed to check the condition of the battery.

NOTE: Equipment to perform this test may

be procured from local suppliers of testing

equipment.

To begin, charge the battery, if necessary, until all cells

are at least

1.200

specific gravity.

1. If unable to obtain specific gravity 1.200 @ 80°F. in

all cells, replace battery.

2. If able to obtain a specific gravity of 1.200 or more

@ 80°F. in all cells, remove the vent caps and

connect a 300 amp. load for 15 seconds.

a. If smoke occurs in one or more cells, replace the

battery.

b. If smoke does not occur proceed to step 3.

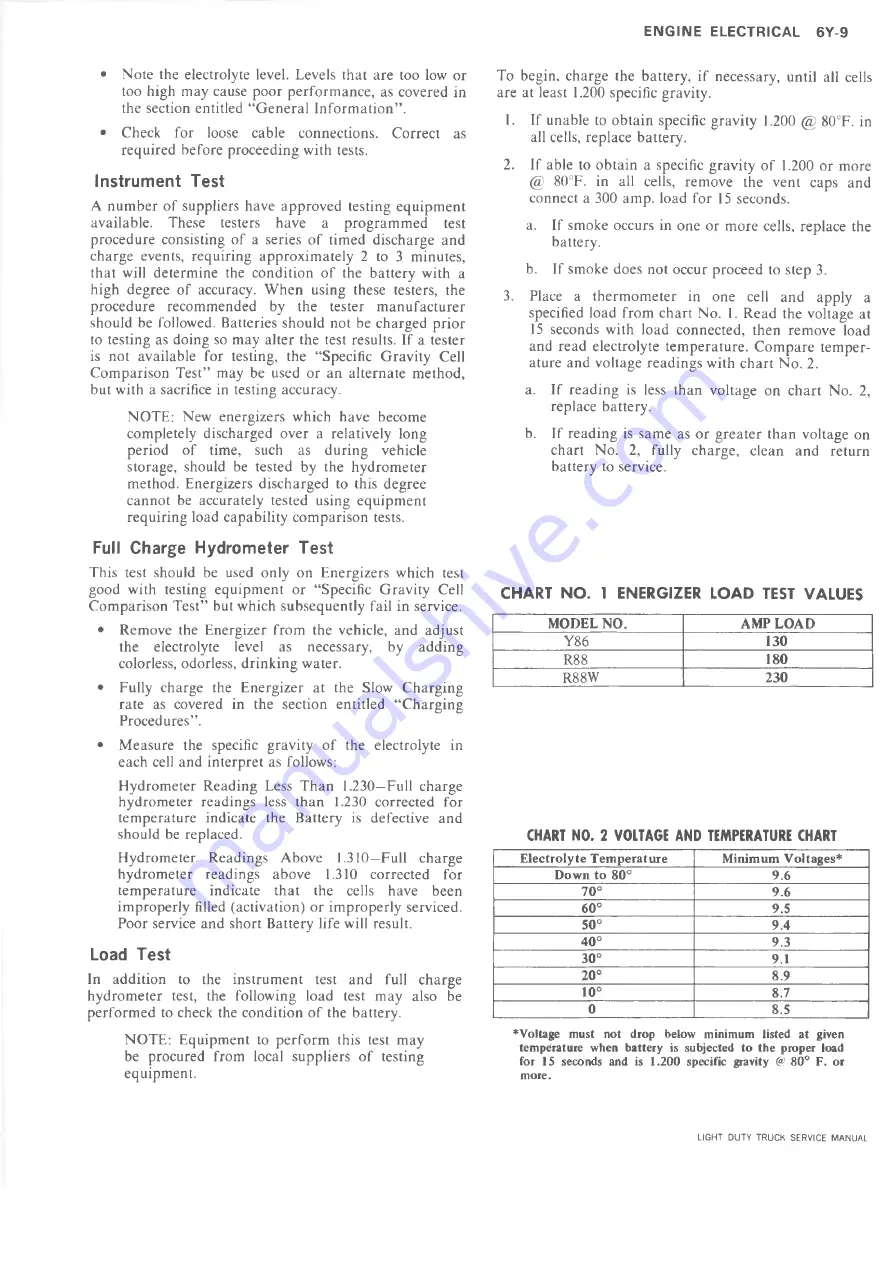

3. Place a thermometer in one cell and apply a

specified load from chart No. 1. Read the voltage at

15 seconds with load connected, then remove load

and read electrolyte temperature. Compare temper

ature and voltage readings with chart No. 2.

a. If reading is less than voltage on chart No. 2,

replace battery.

b. If reading is same as or greater than voltage on

chart No. 2, fully charge, clean and return

battery to service.

CHART NO . 1 ENERGIZER LOAD TEST VALUES

MODEL NO.

AMP LOAD

Y

86

130

R

88

180

R

88

W

230

CHART NO. 2 VOLTAGE AND TEMPERATURE CHART

Electrolyte Temperature

Minimum Voltages*

Down to 80°

9.6

70°

9.6

60°

9.5

50°

9.4

o

O

■'t

9.3

0

O

co

9.1

o

O

8.9

10°

8.7

0

8.5

♦Voltage must not drop below minimum listed at given

temperature when battery is subjected to the proper load

for 15 seconds and is 1.200 specific gravity @ 8 0 ° F. or

more.

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......