9 -2 8 STEERING

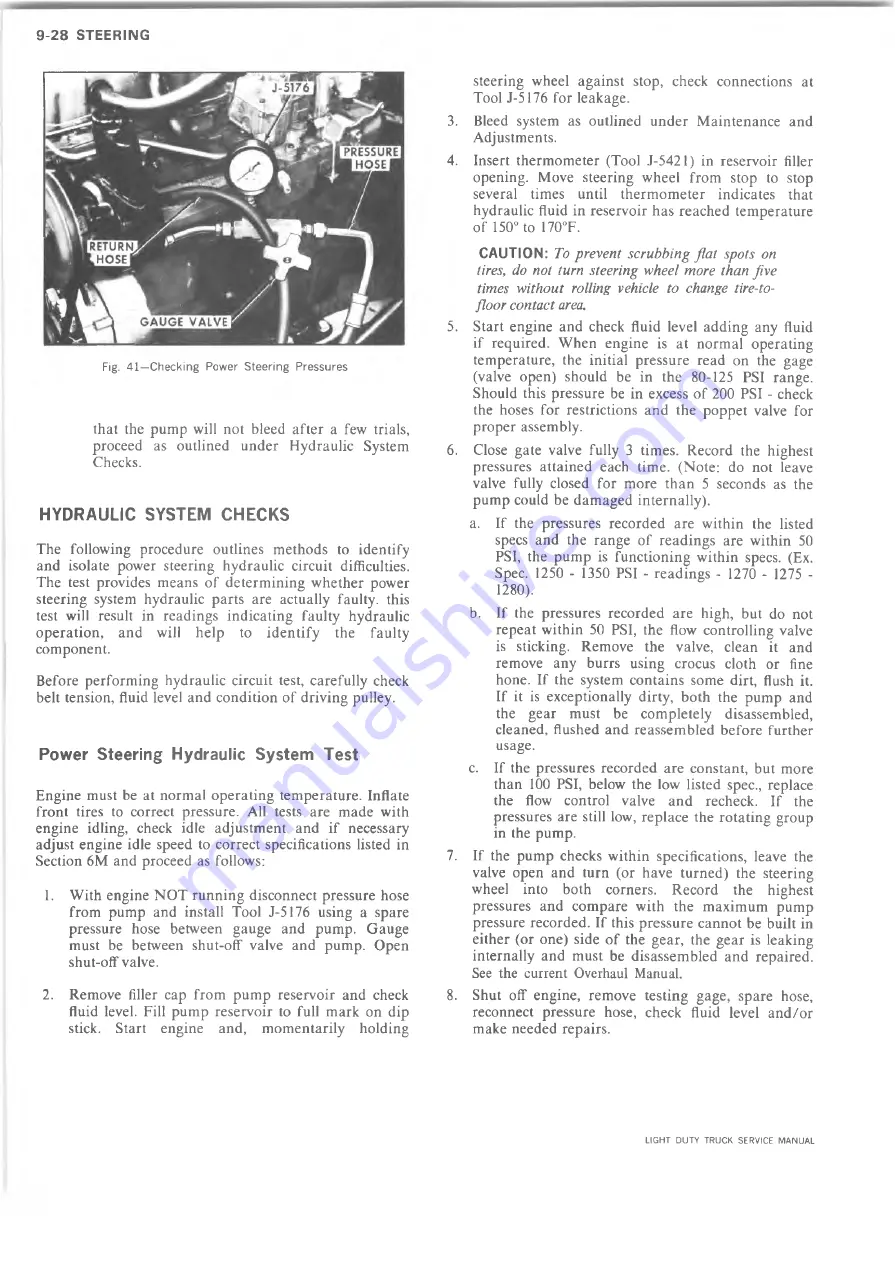

Fig. 4 1 —C h e c k in g P o w er S te e r in g P res s u re s

that the pump will not bleed after a few trials,

proceed as outlined under Hydraulic System

Checks.

HYDRAULIC SYSTEM CHECKS

The following procedure outlines methods to identify

and isolate power steering hydraulic circuit difficulties.

The test provides means of determining whether power

steering system hydraulic parts are actually faulty, this

test will result in readings indicating faulty hydraulic

operation, and will help to identify the faulty

component.

Before performing hydraulic circuit test, carefully check

belt tension, fluid level and condition of driving pulley.

Power Steering Hydraulic System Test

Engine must be at normal operating temperature. Inflate

front tires to correct pressure. All tests are made with

engine idling, check idle adjustment and if necessary

adjust engine idle speed to correct specifications listed in

Section 6M and proceed as follows:

1. With engine NOT running disconnect pressure hose

from pump and install Tool J-5176 using a spare

pressure hose between gauge and pump. Gauge

must be between shut-off valve and pump. Open

shut-off valve.

2. Remove filler cap from pump reservoir and check

fluid level. Fill pump reservoir to full mark on dip

stick. Start engine and, momentarily holding

steering wheel against stop, check connections at

Tool J-5176 for leakage.

3. Bleed system as outlined under Maintenance and

Adjustments.

4. Insert thermometer (Tool J-5421) in reservoir filler

opening. Move steering wheel from stop to stop

several times until thermometer indicates that

hydraulic fluid in reservoir has reached temperature

of 150° to 170°F.

CAUTIO N:

To prevent scrubbing flat spots on

tires, do not turn steering wheel more than five

times without rolling vehicle to change tire-to-

floor contact area.

5. Start engine and check fluid level adding any fluid

if required. When engine is at normal operating

temperature, the initial pressure read on the gage

(valve open) should be in the 80-125 PSI range.

Should this pressure be in excess of 200 PSI - check

the hoses for restrictions and the poppet valve for

proper assembly.

6. Close gate valve fully 3 times. Record the highest

pressures attained each time. (Note: do not leave

valve fully closed for more than 5 seconds as the

pump could be damaged internally).

a. If the pressures recorded are within the listed

specs and the range of readings are within 50

PSI, the pump is functioning within specs. (Ex.

Spec. 1250 - 1350 PSI - readings - 1270 - 1275 -

1280).

b. If the pressures recorded are high, but do not

repeat within 50 PSI, the flow controlling valve

is sticking. Remove the valve, clean it and

remove any burrs using crocus cloth or fine

hone. If the system contains some dirt, flush it.

If it is exceptionally dirty, both the pump and

the gear must be completely disassembled,

cleaned, flushed and reassembled before further

usage.

c. If the pressures recorded are constant, but more

than 100 PSI, below the low listed spec., replace

the flow control valve and recheck. If the

pressures are still low, replace the rotating group

in the pump.

7. If the pump checks within specifications, leave the

valve open and turn (or have turned) the steering

wheel into both corners. Record the highest

pressures and compare with the maximum pump

pressure recorded. If this pressure cannot be built in

either (or one) side of the gear, the gear is leaking

internally and must be disassembled and repaired.

See the current Overhaul Manual.

8. Shut off engine, remove testing gage, spare hose,

reconnect pressure hose, check fluid level and/or

make needed repairs.

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......