1A-60 HEATER A N D AIR C O N D I T I O N I N G

3. Using needle-nose pliers, remove the expansion

tube from the evaporator core inlet line (fig. 60).

4. Remove the expansion tube "O " ring from the core

inlet line.

5. To install, reverse Steps l-4 above.

NOTE: Install the expansion tube using a

new "O" ring, coated with clean refrigeration

oil.

6. Evacuate, charge and check the system.

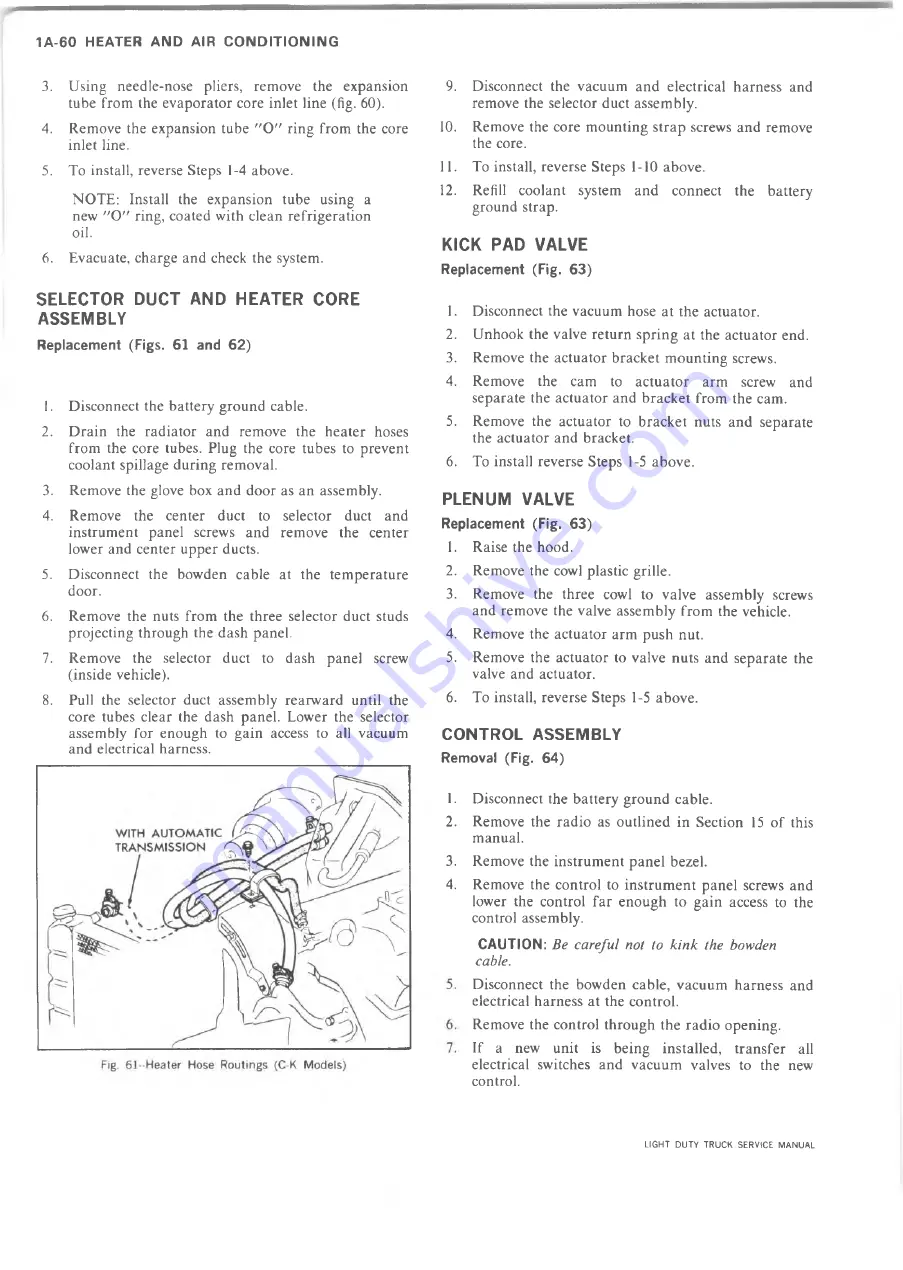

SELECTOR DUCT AND HEATER CORE

ASSEMBLY

Replacement (Figs. 61 and 62)

1. Disconnect the battery ground cable.

2. Drain the radiator and remove the heater hoses

from the core tubes. Plug the core tubes to prevent

coolant spillage during removal.

3. Remove the glove box and door as an assembly.

4. Remove the center duct to selector duct and

instrument panel screws and remove the center

lower and center upper ducts.

5. Disconnect the bowden cable at the temperature

door.

6. Remove the nuts from the three selector duct studs

projecting through the dash panel.

7. Remove the selector duct to dash panel screw

(inside vehicle).

8. Pull the selector duct assembly rearward until the

core tubes clear the dash panel. Lower the selector

assembly for enough to gain access to all vacuum

and electrical harness.

9. Disconnect the vacuum and electrical harness and

remove the selector duct assembly.

10. Remove the core mounting strap screws and remove

the core.

11. To install, reverse Steps 1-10 above.

12. Refill coolant system and connect the battery

ground strap.

KICK PAD VALVE

Replacement

(Fig. 63)

1. Disconnect the vacuum hose at the actuator.

2. Unhook the valve return spring at the actuator end.

3. Remove the actuator bracket mounting screws.

4. Remove the cam to actuator arm screw and

separate the actuator and bracket from the cam.

5. Remove the actuator to bracket nuts and separate

the actuator and bracket.

6. To install reverse Steps 1-5 above.

PLENUM VALVE

Replacement

(Fig. 63)

1. Raise the hood.

2. Remove the cowl plastic grille.

3. Remove the three cowl to valve assembly screws

and remove the valve assembly from the vehicle.

4. Remove the actuator arm push nut.

5. Remove the actuator to valve nuts and separate the

valve and actuator.

6. To install, reverse Steps 1-5 above.

CONTROL ASSEMBLY

Removal

(Fig. 64)

1. Disconnect the battery ground cable.

2. Remove the radio as outlined in Section 15 of this

manual.

3. Remove the instrument panel bezel.

4. Remove the control to instrument panel screws and

lower the control far enough to gain access to the

control assembly.

CAUTIO N:

Be careful not to kink the bowden

cable.

Disconnect the bowden cable, vacuum harness and

electrical harness at the control.

Remove the control through the radio opening.

If a new unit is being installed, transfer all

electrical switches and vacuum valves to the new

control.

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......