SKU 91062

PAGE 12

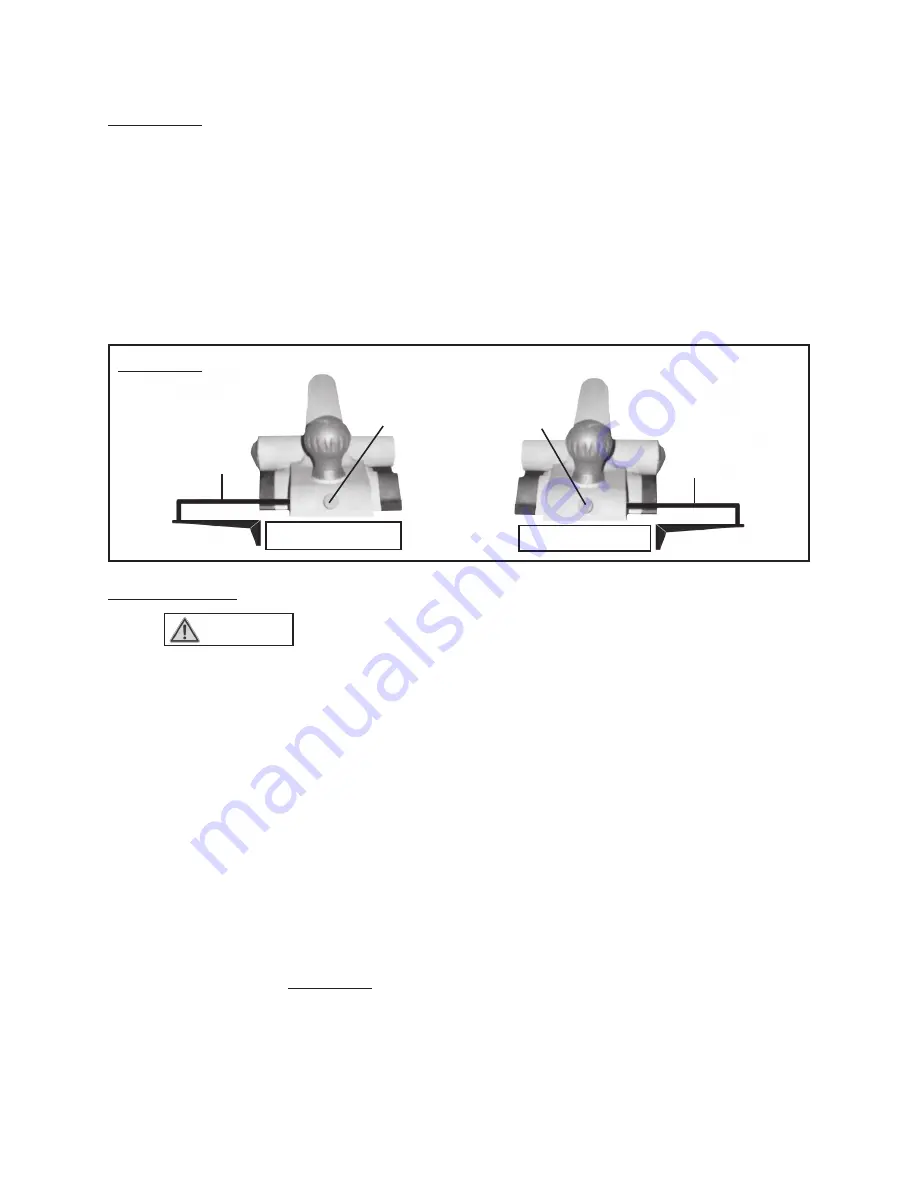

The Guide:

1.

The Guide (64) can be used to adjust the width of cut, support the Planer, and

keep the Planer from drifting away from the cut line (i.e., the edge of a door).

The Guide may be attached either to the right side of the Planer or on its left

side. To do so, position the Planer on the wood stock that is to be cut. Loosen

the Screw (47) located at the front of the Planer. Insert the Guide into the mount-

ing hole located on either side toward the front of the Planer. Slide the Guide in

until it contacts the edge of the wood stock. Then, lock the Guide in place by

retightening the Screw.

(See Figure F.)

GUIDE

(64)

GUIDE

(64)

SCREW

(47)

SCREW

(47)

WOOD STOCK

WOOD STOCK

FIGURE F

To Make A Cut:

1.

CAUTION!

Make sure the Trigger (16) is in its “OFF” position, and that the

Planer is unplugged from its 120 volt, grounded, electrical outlet.

Then,

make any

necessary adjustments to the cutting depth and cutting width of the Planer.

(See Figures E, and F.)

2.

Whenever possible, use clamps, a vise, or other safe, practical ways to hold and

support the wood stock.

3.

While standing to the

side of the wood stock, hold the Planer firmly with one hand

on the handle portion of the Housing (15, 45), and the other hand on the Depth

Knob (48).

4.

Set the Front Base Plate (54) of the Planer on the front edge of the wood stock.

Then, depress the Safety Lock Button (17) and squeeze the Trigger (16) to start

the Planer.

IMPORTANT:

Do not allow the Blades (57) of the Planer to contact

the wood stock until the Blades are spinning at full speed.

(See Figure G, next page.)

5.

While placing pressure on the Front Base Plate (54) to control the depth of cut,

and while placing pressure on the Guide (64) against the wood stock to control

the width of cut, feed the Planer slowly until the Rear Base Plate (61) contacts