Page 10

For technical questions, please call 1-800-444-3353.

SKU 91222

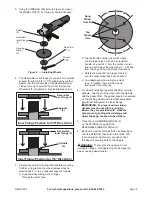

Installing a Threaded Accessory

TO PREVENT INJURY: Wear heavy-duty work gloves

when handling wire wheels and brushes. These

accessories are sharp and can cause injury.

1. The accessory MUST be:

• rated to at least 11,000 RPM.

• no larger than 4″ in diameter.

• fitted with a threaded opening of

5/8″ x 11 TPI.

• undamaged.

• a sanding disc and backing pad, a sanding

flap disc, a wire wheel or a wire cup

brush (accessories not included).

2. Press in and hold the LOCK PIN (12) to

prevent the Spindle from turning.

3. Remove the Outer Flange and the Inner

Flange and keep in a safe place.

4. Thread disc accessory firmly onto the

Spindle. Wrench tighten onto the spindle.

Work Piece and Work

Area Set Up

1. Designate a work area that is clean and well-lit.

The work area must not allow access by children

or pets to prevent distraction and injury.

2. Route the power cord along a safe route to reach

the work area without creating a tripping hazard or

exposing the power cord to possible damage. The

power cord must reach the work area with enough

extra length to allow free movement while working.

3. Secure loose work pieces using a vise or clamps

(not included) to prevent movement while working.

4. There must not be hazardous objects, such

as utility lines or foreign objects, nearby that

will present a hazard while working.

5. You must use personal safety equipment including,

but not limited to, ANSI-approved eye and hearing

protection, as well as heavy-duty work gloves.

6. Before beginning work, provide for sparks and

debris that will fly off the work surface.

General Operating Instructions

TO PREVENT SERIOUS INJURY: Grip the tool firmly

with both hands.

1. Make sure that the SLIDE SWITCH (19)

is not locked on, then plug in the tool.

2. Slide the SLIDE SWITCH (19)

forward to start the tool.

Figure 4 - Turning ON the Grinder

Slide Switch

(19)

3. Allow the tool to come up to full speed

before touching the work material.

4. Apply the wheel to the work material at a 10° – 15°

angle, allowing the tool to operate at full speed.

If the tool bogs down, use lighter pressure.

Work

Surface

NOTE:

Motor may heat up with the prolonged

medium to heavy use. To avoid motor burnout,

do not operate beyond a 15 to 20 minute

duty cycle when using heavy force.

5. To create a smoother surface, keep the tool

moving over the work surface.

6. Slide the SLIDE SWITCH (19) back to stop the tool.

7. Allow the tool to come to a complete

stop before setting it down.

8. To prevent accidents, turn off the tool and

disconnect its power supply after use. Clean, then

store the tool indoors out of children’s reach.