SKU 93749

For technical questions, please call 1-800-444-3353.

Page 7

SpEciFicatiONS

Electrical Requirements 120 V~ / 60 Hz / 6A

Staple Type

1/4”, 5/16”, 1/2”, 9/16”

or Arrow T50

®

Nail Type

9/16”

Accessories

3/8” Staples (Qty. 400)

9/16” Nails (Qty. 100)

Note:

Performance of the Stapler/Nailer

may vary depending on variations

in local line voltage. Extension cord

usage may also affect the tool perfor-

mance.

uNpacKiNg

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at the number shown on the

cover of this manual as soon as possible.

lOadiNg

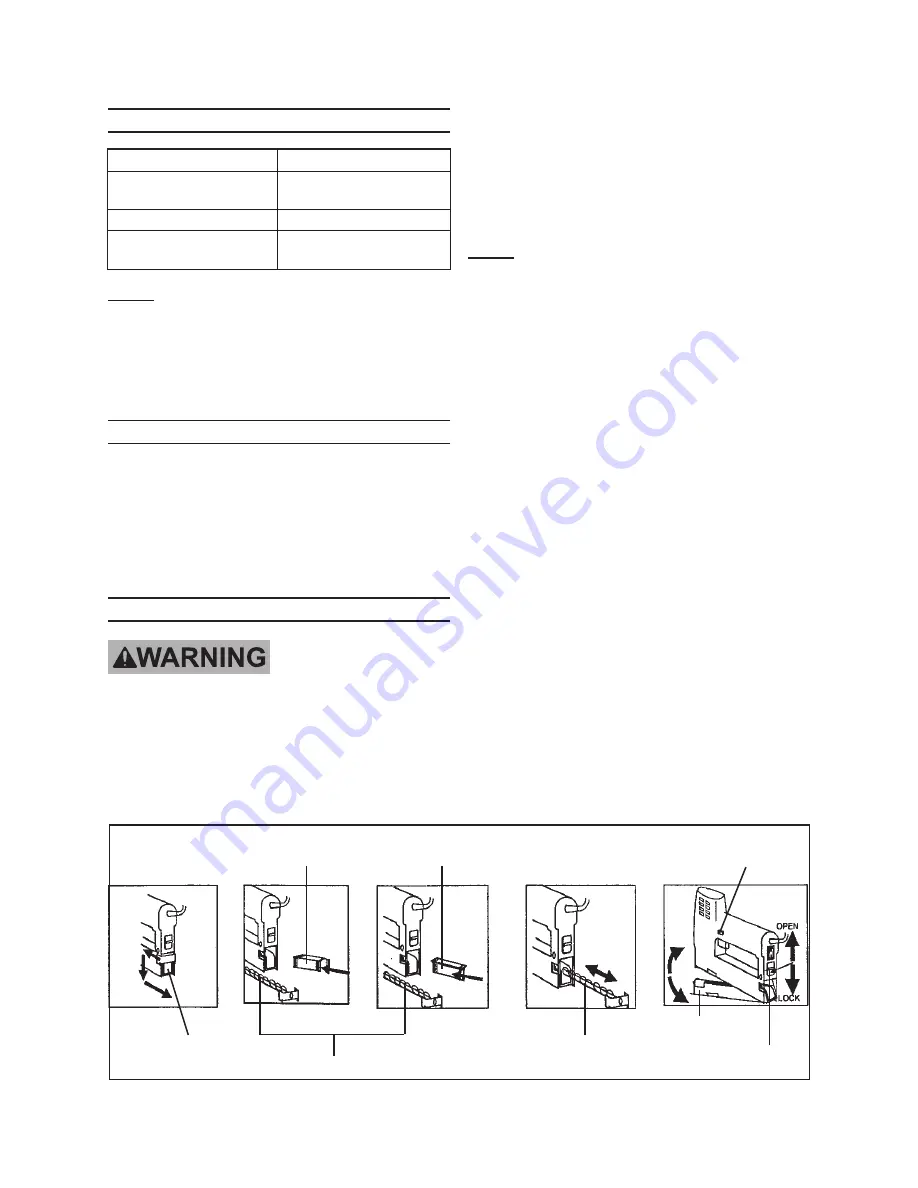

tO prEVENt

SEriOuS iNjurY:

Wear aNSi-approved impact

safety goggles when

reloading or performing any

other maintenance on this

tool.

Other people in the work

area must also wear ANSI-

approved impact safety goggles.

lock the trigger (10) by moving

1.

the trigger lock (3) to the right

and unplug the tool before loading.

Note:

To

lock

the Trigger (10), move the

Trigger Lock (3) to the

right

.

To

unlock

the Trigger, move the Trig-

ger Lock to the

left

.

test for proper operation of the

2.

Trigger Lock by attempting to fire a

fastener into a piece of scrap wood

while the trigger is locked (the tool

should not fire). (See Figure H.)

Push forward on the Pusher Cover

3.

(2) and slightly downward to remove

the Pusher assembly.

(See Figure d.)

Once removed, insert one strip of

4.

Staples (46)

or

Nails (47) in the Inner

Staple Slot (1-1).

do not load Sta-

ples and Nails together.

(See Figures E, F.)

Reinsert the Pusher assembly into

5.

the Stapler/Nailer, making sure the

Pusher Cover (2) locks securely in

place.

(See Figure g.)

H

g

F

E

d

magaziNE

lOcK (44)

OutEr StaplE

SlOt (1)

StaplES

(46)

NailS

(47)

puSHEr cOVEr

(2)

triggEr lOcK

(3)

puSHEr aSSY.

puSHEr aSSY.