Page 10

SKU 97114

For technical questions, please call 1-800-444-3353.

to press the POWER button once to

start the 80 seconds cool air function.

Choose the appropriate heat level

3.

for the job and push the “

+

” or “

–

” to

adjust the heat settings. The LEDs

will light up to indicate the heat level.

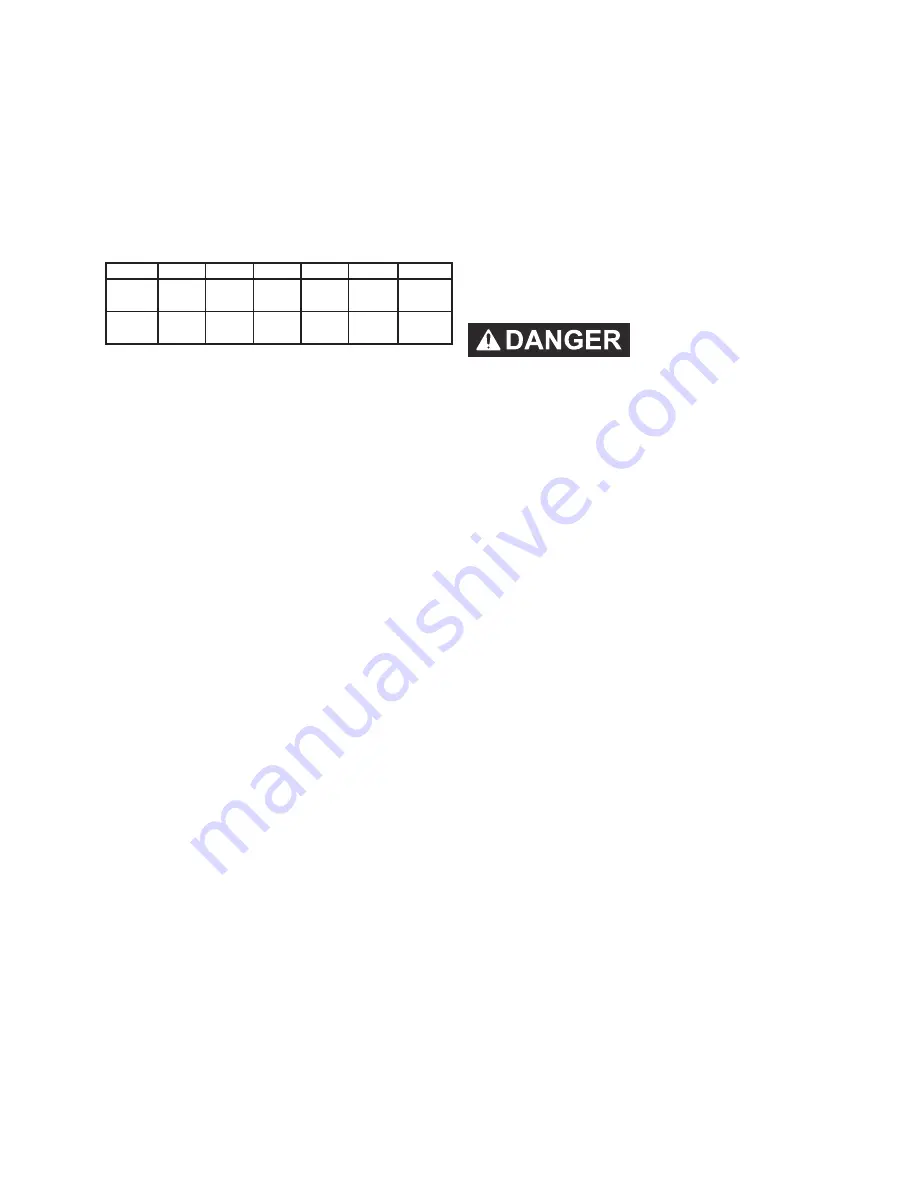

# LEDs

1

2

3

4

5

6

Low

Temp.

430° F 550° F 650° F 700° F 730° F 800° F

High

Temp.

570° F 660° F 730° F 790° F 970° F 1160° F

The Heat Gun can be used for:

4.

Shrinking of shrinkdown

•

tubing, packaging and electrical

components.

Deforming of articles made from

•

acrylic, PVC, and polystyrene

tubing, plates, and profiles as well

as most woods.

Welding of thermoplastic polymer,

•

flooring materials of PVC and

linoleum, PVC-coated fabric,

wallpaper, tarpaulins and foils.

Soldering of tin, special silver

•

solder, SMD elements, cable

lugs, and for loosening soldered

connections.

Paint removal. Removal of old

•

coatings of oil paint, varnish, and

synthetic plaster.

Drying of color shade samples,

•

filter, adhesives, construction joints

and stucco forms.

Joining adhesives. Large surface

•

gluing with contact adhesives,

activation of pressure, or heat

sensitive adhesives, acceleration

of bonding processes, releasing of

bonding points as well as releasing

or bonding of edge bond or veneer.

Defrosting of icy stairs and steps,

•

door locks, trunk lids, car doors or

water pipes.

Disinfection. With the tool set at the

•

highest setting, animal sites/stables

may be disinfected. Wood worm

infestation may be controlled. Do

not heat up the wood surface too

much or it can burn.

never touch work

area with the Heat

gun; it could burn or ignite.

When the job is finished, push the

5.

“POWER” button to turn the unit off

and allow the Heat Gun to cool down

on a inflammable surface.

To prevent accidents, turn off the

6.

tool and disconnect its power supply

after use. Clean, then store the tool

indoors out of children’s reach.