SKU 99683

for technical questions, please call 1-800-444-3353.

Page 8

the Battery is charged, unplug the

Charger from the electrical outlet and

remove the Bat tery from the Charger.

Remove the Screw Length Adjust

-

2.

ment by turning it counterclockwise

with a 3mm hex key. Move the ex-

tension tip of the Screwdriver to work

with the size of screw being used.

The Screwdriver can be used with

screws 0.9” (25mm) to 2.1” (55mm)

long and with a diameter from 0.137”

(3.5mm) to 0.177” (4.5mm). Refer to

the scale on the extended tip. The

front of the Screwdriver must extend

beyond the tip of the screw. If the ex-

tended tip of the screwdriver does not

project beyond the tip of the screw far

enough, the next screw will not have

enough room to advance before be-

ing driven. Tighten the screw again.

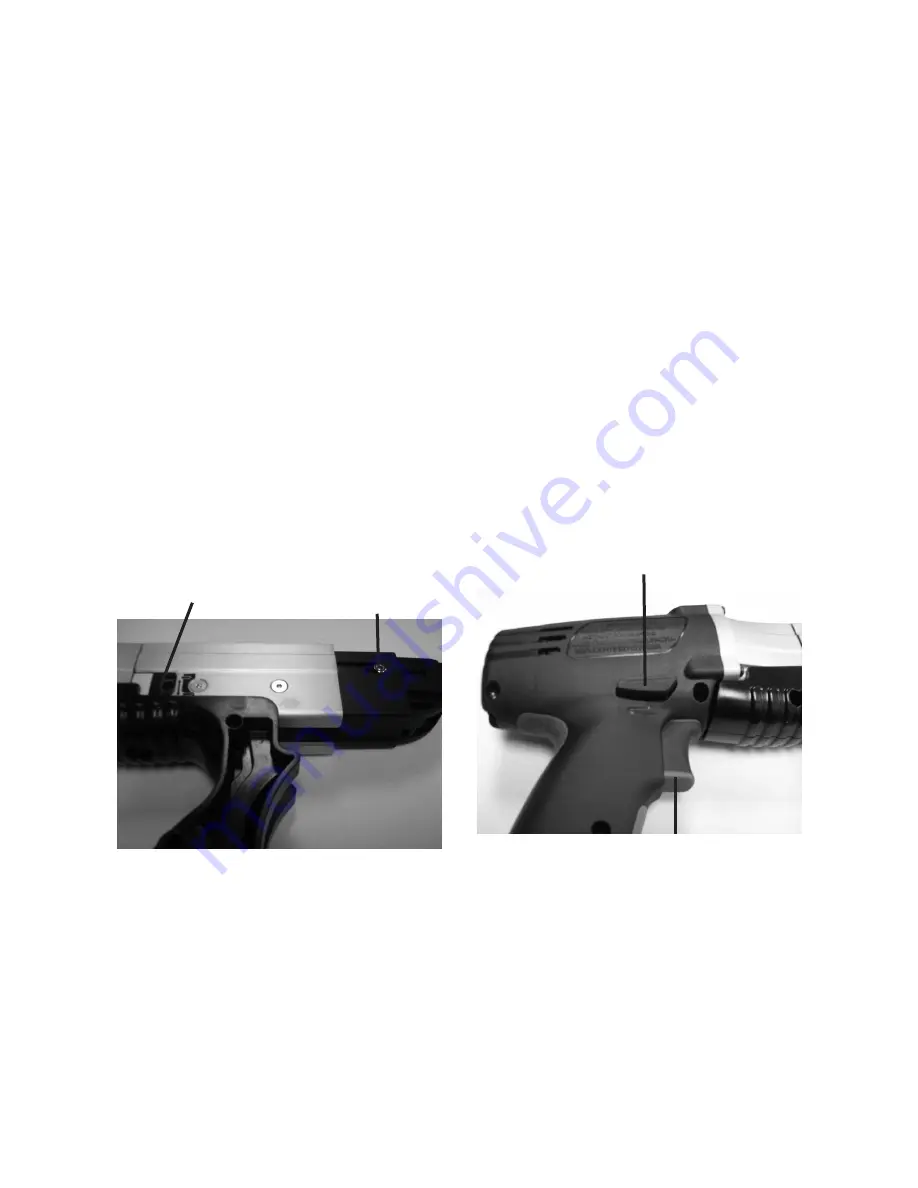

depth

adjustment

dial

screw

length

adjustment

3.

Turn the Depth Adjustment Dial to set

the point at which the Screwdriver

stops driving. The Depth Adjustment

can be used to drive the screw so

that it is recessed, flush, or sticking

out of the work surface.

Rotate the bottom portion of the Front

4.

Handle (25) down and feed a screw

strip up through the handle and then

through the tip.

Feed the screw strip through until the

5.

second empty slot is aligned with the

bit.

Push the Battery onto the bottom of

6.

the tool until it snaps into place.

Move the Forward/Reverse Switch to

7.

the Forward position.

Address the tip of the Screwdriver to

8.

the work surface and hold the Trigger

down.

Allow the Screwdriver to build up to

9.

speed and push the screw into the

work surface at a 90° angle. Use

light but consistent pressure to drive

the screw.

trigger

forward/reverse

switch

10. Do not remove the tool from the work

surface until the clutch disengages

and the screw stops turning.

The next screw will automatically

11.

feed into place when the tip is pushed

against the work surface.

When finished, move the Forward/

12.

Reverse Switch to the middle, locked