6.

DRESS SAFELY. Non-skid footwear or safety shoes should be used when

working with this product. Do not wear loose clothing or jewelry as they can

become caught in moving parts. Wear a protective hair covering to prevent long

hair from becoming caught in moving parts. If wearing a long-sleeve shirt, roll

sleeves up above elbows.

7.

INDUSTRIAL APPLICATIONS MUST FOLLOW OSHA REQUIREMENTS.

8.

DO NOT OVERREACH. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etcetera.

9.

STAY ALERT. Watch what you are doing at all times. Use common sense. Do

not use this product when you are tired or distracted from the job at hand.

10.

CHECK FOR DAMAGED PARTS. Before using this product, carefully check that

it will operate properly and perform its intended function. Check for damaged

parts and any other conditions that may affect the operation of this product.

Replace or repair damaged or worn parts immediately.

11.

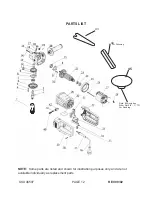

REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only

identical replacement parts. Only use accessories intended for use with this

product. Approved accessories are available from Harbor Freight Tools.

12.

MAINTAIN THIS PRODUCT WITH CARE. Keep this tool clean and dry for better

and safer performance.

13.

MAINTENANCE: For your safety, service and maintenance should be performed

regularly by a qualified technician.

14.

USE THE RIGHT PRODUCT FOR THE RIGHT JOB. There are certain

applications for which this product was designed. Do not use small equipment,

tools or attachments to do the work of larger industrial equipment, tools or

attachments. Do not use this product for a purpose for which it was not intended.

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1.

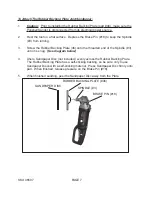

MAKE SURE THE POWER SWITCH (part #33) IS IN THE “OFF” POSITION

BEFORE PLUGGING IN THE POWER CORD (part #36).

2.

DO NOT ABUSE THE POWER CORD. Do not use the Power Cord (part #36) to

pull the Plug from a power outlet. Keep Power Cord away from heat, oil, sharp

edges, and moving parts. Replace a damaged Power Cord immediately. Route

the Power Cord safely. Protect it from being damaged by other equipment in the

work area. Do not route the Power Cord where it can be walked on or tripped

over.

SKU 46507

PAGE 3