7 / 15 - © CP

5. Startup

Remove the device, including supplied parts.

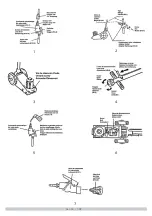

Connect the upper handle to the lower one. To do so, make sure that internal guideways interlock.

Now connect the two outer poles with each other to position the handle.

Now insert the hexagonal screw and fasten it. This way, both handle ends are secured.

Loosen the screw on the rear side, at the lever recess. Now insert the entire handle into the opening of the lever recess. To do

so, pay attention to the correct positioning (lever pin in opening of lever recess). If it is not locked correctly at once, turn the upper

adjusting knob slightly, until the lever pin located inside slides into the opening of the lever recess.

Now fasten the screw previously unscrewed under point 5. Thus, the lever is secured in the recess.

Attaching the adapter receptacl

The adapter receptacle included in the delivery can be attached to any position of the lever using the supplied clamp.

Use supplied split pins to prevent adapters from falling out.

•

•

•

•

•

•

•

•

6. Using the device for work

Before startup, the oil transport screw must be replaced with the air-vent screw!

Safety guidelines specifed under point 4 are to be observed during work with the jack at all times.

After the lever is coupled to the air supply (fgure 1), it must be positioned below the lifting points of the automobile/truck using the lifting cyl -

inder. (Maximum lifting capacity of the lever is achieved, when the operating pressure is 10 bar.) By pressing the trigger (hand wheel is closed,

see fgure) the load is lifted to the required level (secure with support trestles). The built-in overload safety device (overload valve) ensures that

the load to be lifted never exceeds the jack’s capacity.

Lowering the load

In order to lower the load, please turn the hand wheel counter-clockwise SLOWLY as shown in the picture.

Adjusting the tilt of the jack

Push the relief lever upwards, as shown in the picture.

Then set the relief lever to the desired position and release the lever.

There are 3 different positions to lock the lever.

Hydraulic systems may collect air in the system, which affects the performance of the lever. Please proceed as follows in order to remove air.

Open the housing cover

Loosen the screw shown in the picture (half turn)

Close the relief valve (hand wheel)

Operate the trigger, and alternatively open and close the screw.

Close the screw, as soon as the piston extends.

Make sure the piston can be extended to its fnal position, otherwise repeat the procedure.

Use a suitable liquid to clean the air flter from time to time, and blow until dry. Make sure contaminations and small particles are removed.

•

•

•

•

•

•

•

•

•

•

8. Damaged devices

9. Disposal of devices

7. Maintenance

The hydraulic unit (pump) is a sealed system, which only requires lubrication of the moving parts under normal working conditions

once a month. If the hydraulic unit was disassembled to replace worn out gaskets, or because oil leaked out, fll oil into the pump

slowly through the opening of the oil screw (pos. 54).

When changing oil, at least once a year, or reflling oil, use oil to fll the cylinder up to the oil intake screw. Please make sure that the

piston is retracted.

All moving parts must be lubricated at regular intervals. Keep the device always clean and away from aggressive chemicals. Do not

leave the jack outdoors.

The oil level in the tank may not exceed the flling plug position, when the piston is completely retracted.

Following table gives information about the required amount of oil and type of oil:

Ölmenge

[l]

0,95

Öltyp

HPL ISO 32

CAUTION!! Never use brake fuid. Too much oil in the pump may cause the device to stop operating.

Additionally, oil or lubrication must be applied to mechanical parts every 2 months

•

•

•

•

•

All damaged, severely worn out or poorly functioning devices MUST BE TAKEN OUT OF OPERATION and labeled with stoppage card.

Repair must be done by a technical expert authorized by the vendor.

The product must be disposed of or recycled according to legislation of the corresponding country.

Summary of Contents for CP9420

Page 14: ...14 15 CP 1 3 2 4 5 6 7...