Overview

To reduce the risk of serious injury or death

to yourself or others, read the Safety

instructions section found on the previous

pages of this manual before operating the

machine.

Design and function

PAC P13 is a hydraulic power pack designed for

operating hydraulic breakers and other hydraulic

machines. No other use is permitted.

PAC P13 is fitted with an 13 HP HONDA air cooled

petrol engine with a hydraulic POD system (power

on demand).

The oil flow is 20-30 ± 2 l.p.m continuous (5-8 US

gal/min).

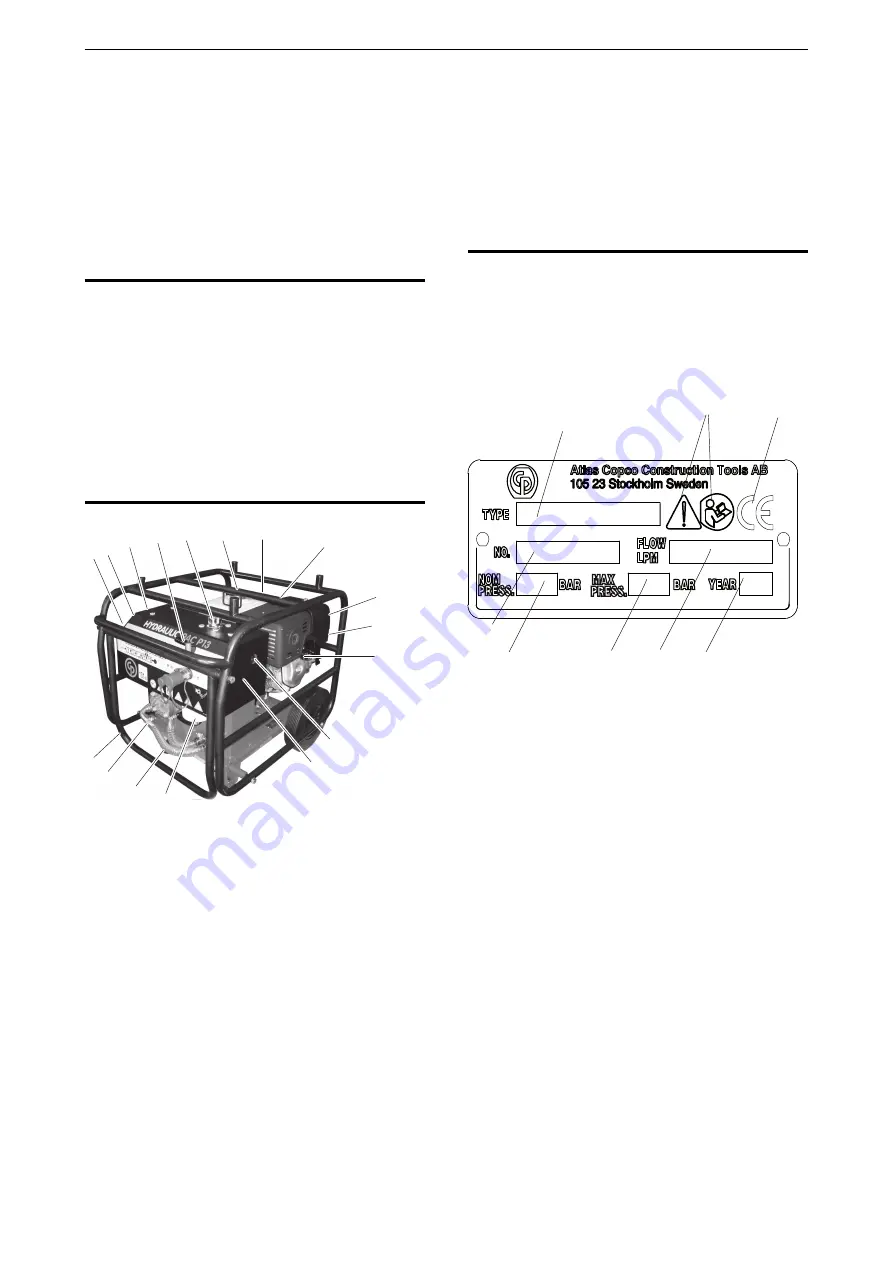

Main parts

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

A.

Filter condition gauge

B.

Oil cooler

C.

Engine oil, dipstick

D.

By-pass valve

E.

Filler cap, hydraulic oil

F.

Filler cap, fuel

G.

Ignition switch OFF and ON

H.

Recoil start

I.

Air filter

J.

Choke control

K.

Fuel tap

L.

Sight glass, hydraulic oil level

M.

Pressure relief valve

N.

Hydraulic oil filter

O.

Drain plug

P.

Hydraulic pump

Q.

Foldable handles

Labels

The machine is fitted with labels containing

important information about personal safety and

machine maintenance. The labels must be in such

condition that they are easy to read. New labels can

be ordered from the spare parts list.

Data plate

Made in Bulgaria

F

D

C

A

B

G

E

H

A.

Maximum permitted hydraulic oil flow

B.

Machine type

C.

Maximum relief valve setting

D.

The warning symbol together with the book

symbol means that the user must read the

safety and operating instructions before the

machine is used for the first time.

E.

Serial number (is also stamped in the valve

housing).

F.

The CE symbol means that the machine is

EC-approved. See the EC declaration which is

delivered with the machine for more

information.

G.

Year of manufacture.

H.

Maximum nominal operating pressure

3392 5183 01b | Original instructions

10

PAC P13

Safety and operating instructions