♦

Check the engine oil level and add oil as

necessary.

♦

Make sure the fuel filler cap is tightly closed.

♦

Place the power pack in a safe position, to prevent

tilting during operation.

♦

Ensure that any machines you plan to use are

compatible with the power pack model used.

♦

Ensure that you have adequate fuel for the job.

Top up as necessary, taking care not to overfill.

♦

If the power pack has a recoil starter for starting

the engine, the cord must not be wound around

the operator's hand when starting the engine.

The first time the power pack is started with new

hoses, these will take approx 1.5 litres (0.4 US gal)

of oil to fill up. Add this amount of oil after the first

start-up.

Start and stop

Changing flow rate

The flow rate can be changed from 20 l.p.m (5 US

gal/min) to 30 l.p.m (8 US gal/min).

1. Loosen the screw (A).

A

2. Move the POD cylinder to the alternative mark.

3. Retighten the screw (A).

Starting the engine

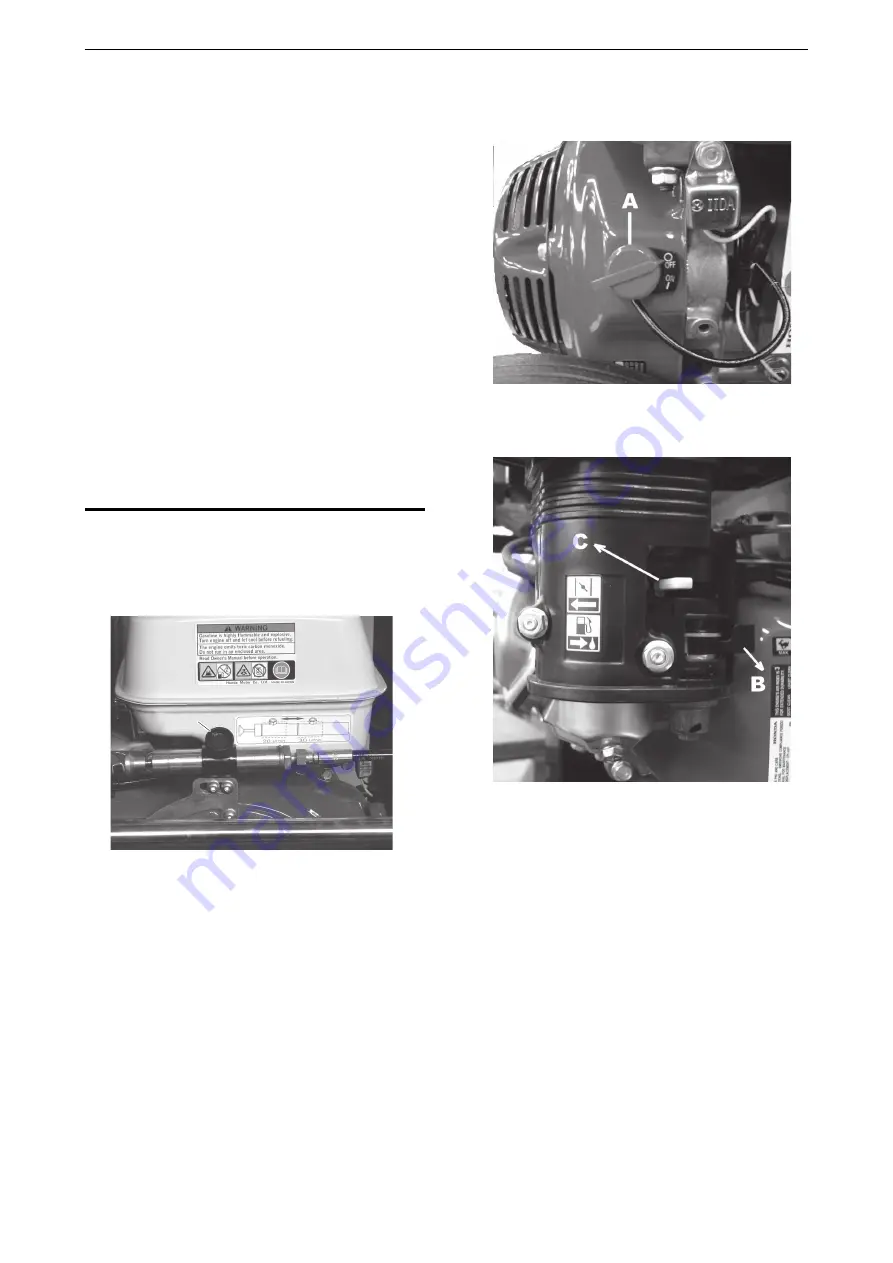

1. Turn the engine switch (A) to position ON.

2. Turn on the fuel by setting the fuel control (B)

to the ON position.

3. Move the choke control (C) to the CLOSE

position. If the engine is warm, or the air

temperature is high, move the choke control to

the OPEN position.

3392 5183 01b | Original instructions

14

PAC P13

Safety and operating instructions