3

Controller

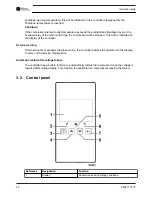

3.1

Controller

Control panel

Introduction

In general, the controller has following functions:

• Controlling the compressor;

• Protecting the compressor;

• Monitoring service intervals;

• Automatic restart after voltage failure (made inactive);

Automatic control of the compressor

The controller maintains the net pressure between programmable limits by automatically loading

and unloading the compressor. A number of programmable settings, e.g. the unloading and

loading pressures, the minimum stop time and the maximum number of motor starts are taken

into account.

The controller stops the compressor whenever possible to reduce the power consumption and

restarts it automatically when the net pressure decreases. If the expected unloading period is to

short, the compressor is kept running to prevent too short standstill periods.

Protecting the compressor

Shutdown temperature warning

The shutdown temperature warning is a programmable warning that advises the operator that the

shutdown temperature is nearly reached. If the measured temperature exceeds the programmed

Instruction book

2920 7114 70

25

Summary of Contents for QRS 10

Page 2: ......

Page 18: ...2 3 Oil system Oil system Oil system units with dryer Instruction book 16 2920 7114 70 ...

Page 23: ...Electric cubicle UL DOL Instruction book 2920 7114 70 21 ...

Page 51: ...208 230 460V 60Hz Instruction book 2920 7114 70 49 ...

Page 74: ...8 Problem solving Control panel Air outlet valve Instruction book 72 2920 7114 70 ...

Page 75: ...Oil filler plug Condensate drain valve on air receiver Instruction book 2920 7114 70 73 ...

Page 84: ......

Page 85: ......

Page 86: ...No 2920 7114 70 2017 03 Printed in Belgium People Passion Performance www cp com ...