To reduce the risk of electrical hazards, fire

hazards or damage to the compressor, use

proper circuit protection. Your compressor

is wired at the factory for operation using

the voltage shown. Connect the compressor

to a power source with the correct breaker

size.

Adequate wiring and motor protection

should be provided for all stationary

compressors. Wiring used for other

machinery should not be used. A

qualified electrician familiar with local

electrical codes in your area should be

used. Size supply wiring per NEC (National

Electric Code) requirements.

WIRING

ALL ELECTRICAL WIRING SHOULD BE DONE

BY A QUALIFIED ELECTRICIAN

General Information

Electrical connections must be properly

grounded. Ground connections should be

connected at the grounding screw.

Overheating, short circuiting and fire damage

will result from inadequate wiring.

WARNING

WARNING

WARNING

CAUTION

WIRING

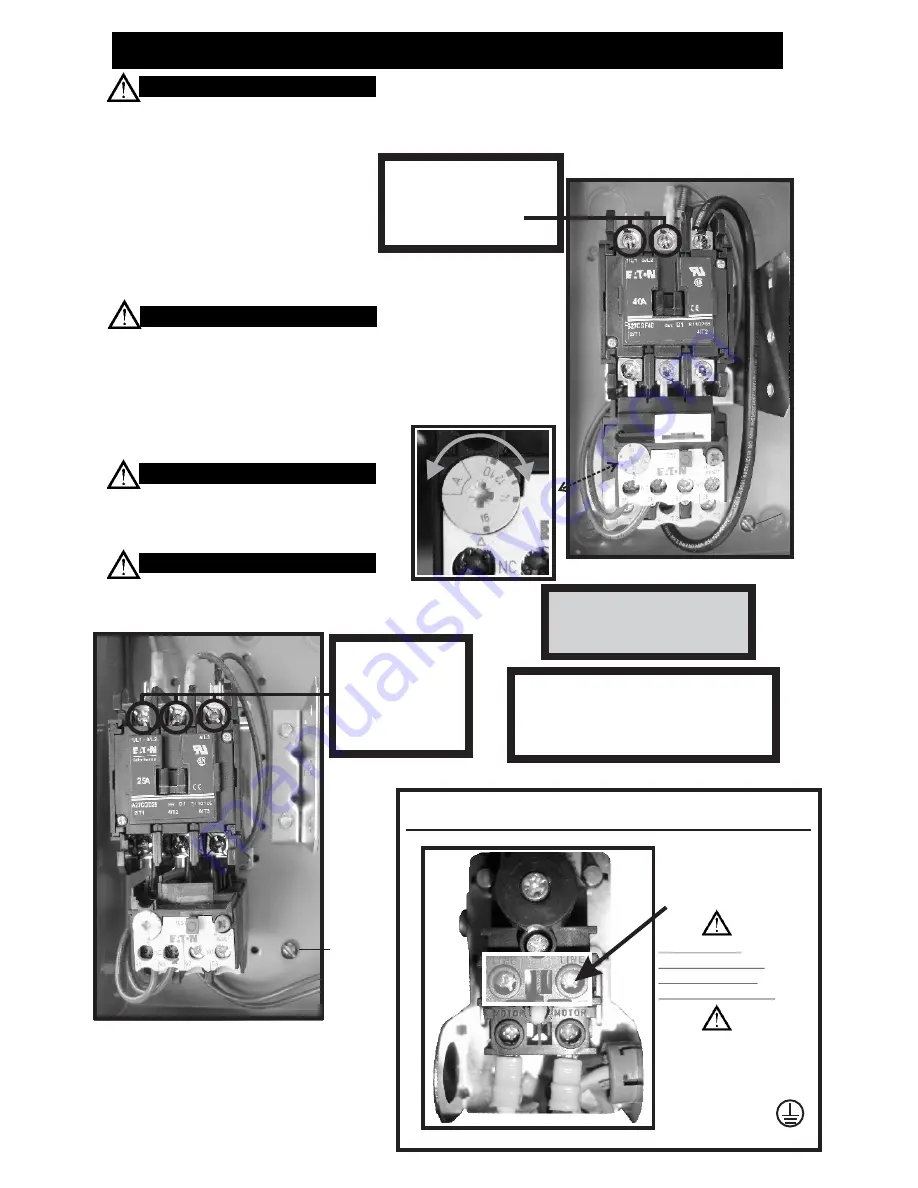

Single Phase

Ground

Incoming power should

be connected to L1 and

L2 at the Top of the

Magnetic Starter.

Three Phase

Ground

Incoming power

should be

connected to

L1, L2 & L3 at

the Top of the

Magnetic Starter.

DO NOT MAKE CONNECTIONS

AT THE PRESSURE SWITCH

(Units with Magnetic Starters)

DUPLEX

Power should be brought into the

left hand starter. Do not bring power

to both starters.

For Models Without Magnetic Starter

Incoming power

should be connected

to the posts

marked (LINE)

Do Not Make

Connections On

Prewired Posts

Marked (MOTOR)!

Electrical connections

must be properly

grounded. Ground

connections should be

connected at a

grounding screw.

Page 6

Overload

Adjustment

+

-