Installation Instructions

PTS SERIES

5

ASSEMBLY AND INSTALLATION

WARNING:

FAILURE TO PROVIDE ADEQUATE

STRUCTURAL STRENGTH FOR THIS COMPONENT CAN

RESULT IN SERIOUS PERSONAL INJURY OR DAMAGE

TO EQUIPMENT! It is the installer’s responsibility to make

sure the structure to which this component is attached can

support five times the combined weight of all equipment.

Reinforce the structure as required before installing the

component.

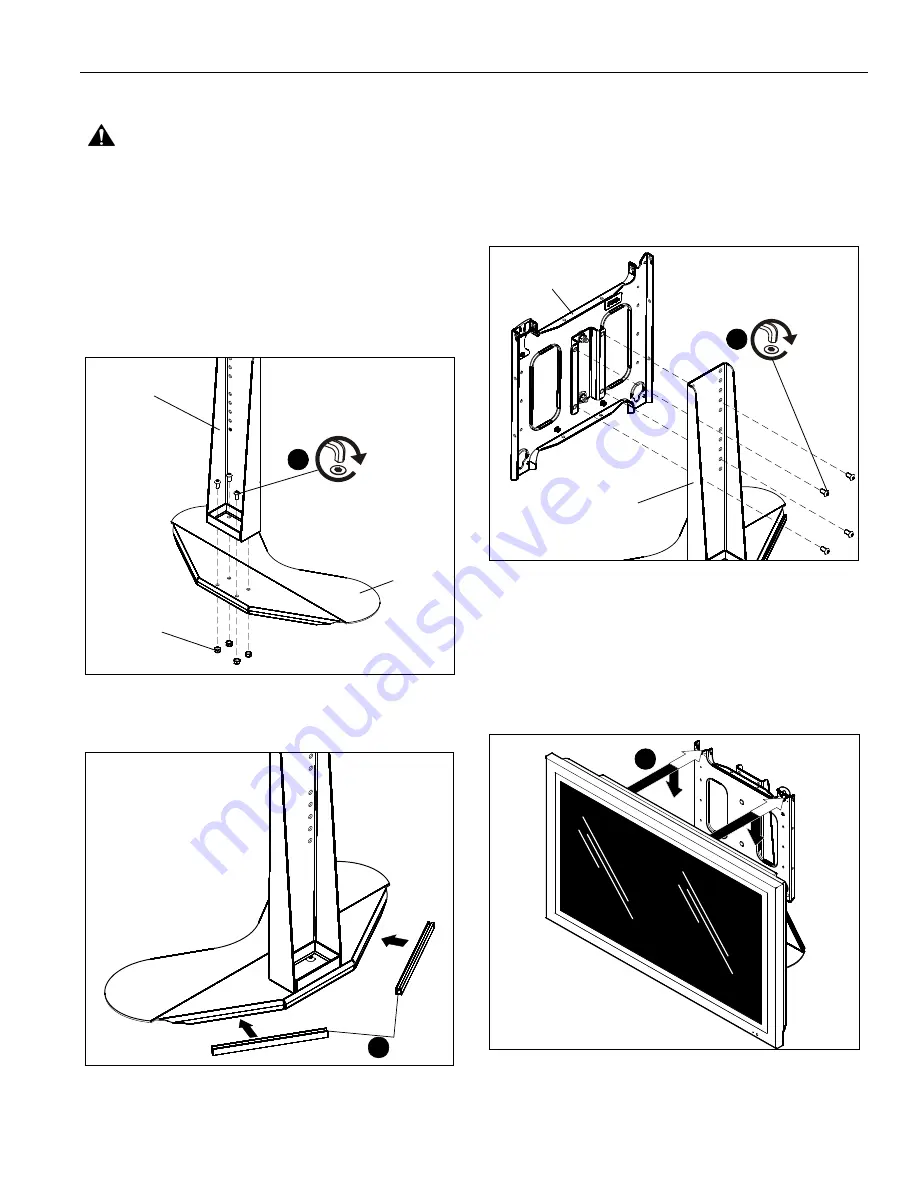

Attaching Post Assembly to Base Assembly

1.

Using four 5/16-18 x 5/8" button head cap screws (F) and

four 5/16-18 Nylock nuts (G), secure post assembly (B) to

base assembly (D). (See Figure 1)

Figure 1

2.

Attach edge trim pieces (C) to the base assembly (D). See

Figure 2.

Figure 2

Attaching Faceplate Assembly

1.

Align mounting holes in faceplate assembly (A) with holes

in post assembly (B). (See Figure 3)

NOTE:

The faceplate assembly can be placed within a four

inch range on the post assembly, dependent on size of

display.

2.

Attach faceplate assembly to post assembly using four

5/16-18 x 5/8" button head cap screws (F). (See Figure 3)

Figure 3

Attaching Interface Bracket to Display

1.

Attach interface bracket to display following instructions

included with interface bracket kit.

Attaching Display to Mount

1.

While supporting both sides of display, align four mounting

buttons on display or interface bracket with four mounting

holes in mount. (See Figures 4 and 5)

Figure 4

1

(F) x 4

(G) x 4

(D)

(B)

(C) x 2

2

2

(F) x 4

(A)

(B)

1