PTS SERIES

Installation Instructions

6

WARNING:

DISPLAY MAY WEIGH IN EXCESS OF 40

LBS! Always use two people and proper lifting techniques

when installing or positioning display on mount.

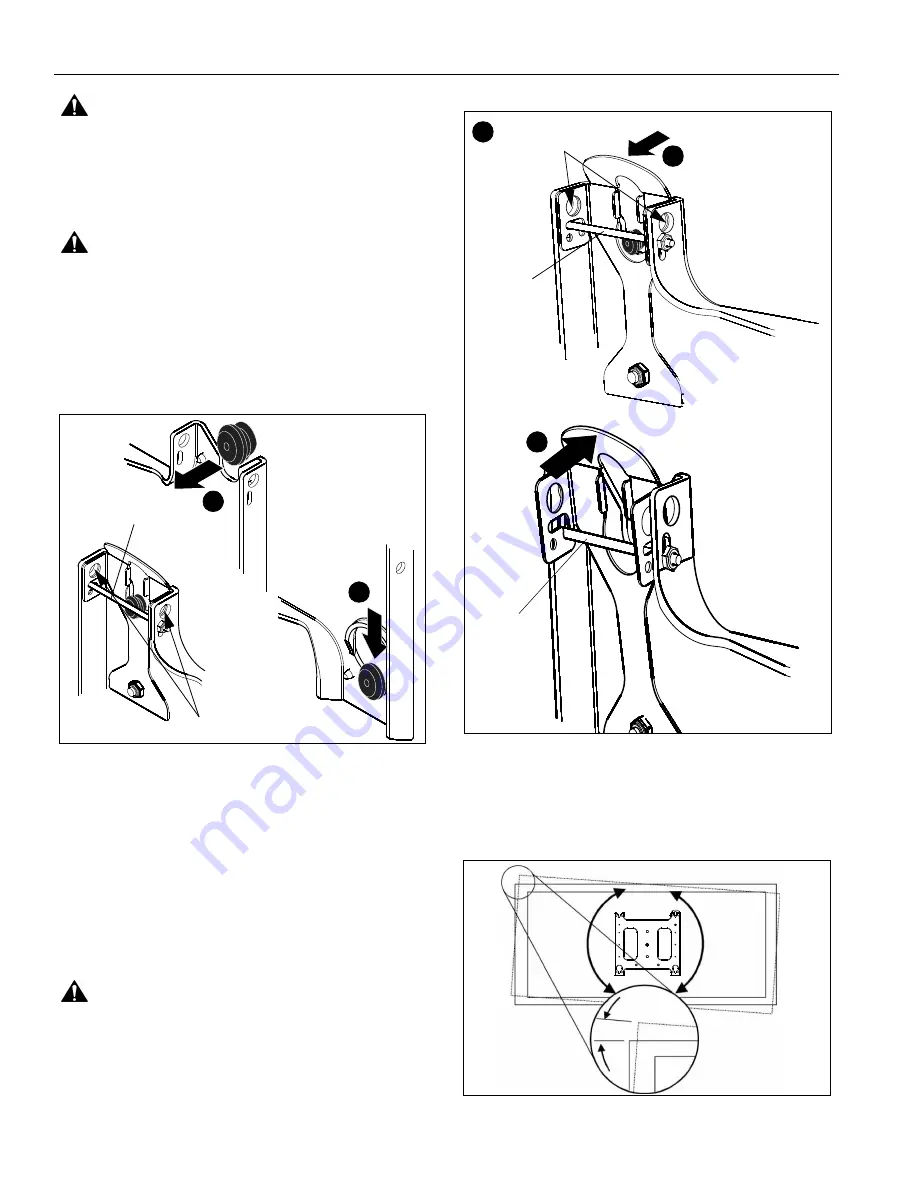

2.

Lower display into place listening for audible "click" to

ensure recessed area of mounting buttons are properly

seated in lower area of mounting holes. (See Fig. 4 and 5)

WARNING:

IMPROPER INSTALLATION CAN LEAD TO

DISPLAY FALLING CAUSING SERIOUS PERSONAL

INJURY OR DAMAGE TO EQUIPMENT! Ensure mounting

buttons are completely engaged in mounting holes.

NOTE:

Holes are provided in the faceplate for use with a

padlock or similar locking device, if desired. In addition,

the pin and nut may be removed from the upper holes

and moved to the lower holes for use as a more

permanent locking device. (See Figure 5).

Figure 5

Removing Display

1.

Disconnect all power/audio/video cables.

2.

Remove bolt or padlock from faceplate (if used).

(See Figure 6)

NOTE:

The pin may have been used as a more permanent

locking device. If so, remove nut and pin and move

from the lower holes to the upper holes.

3.

Pull back on flag on upper mounting hole and press pin

down into "Open" position. (See Figure 6)

WARNING:

THE DISPLAY MAY WEIGH IN EXCESS OF

40 LBS EACH! Always use two people and proper lifting

techniques when installing or positioning display.

4.

Carefully lift display from mount.

5.

Lift up on pin and place flag back against faceplate to return

it to "Closed" position. (See Figure 6)

Figure 6

Adjusting Roll Tension

The faceplate provides 2

o

roll adjustment. (See Figure 7) Roll

adjustment is accomplished by shifting the faceplate right or left

as needed until the faceplate is level.

Figure 7

1

2

May remove

pin and nut and

move to lower holes

A padlock or bolt

may be placed

through latch holes

3

2

Remove bolt

or padlock

if used

Pin in

"Open"

position -

Pin in

"Closed"

position -

5

move to

"Open"

position to

move to

"Closed"

position

remove

display

after display

is removed.