Installation Instructions

Model MSP-SPWH (PWH™)

11

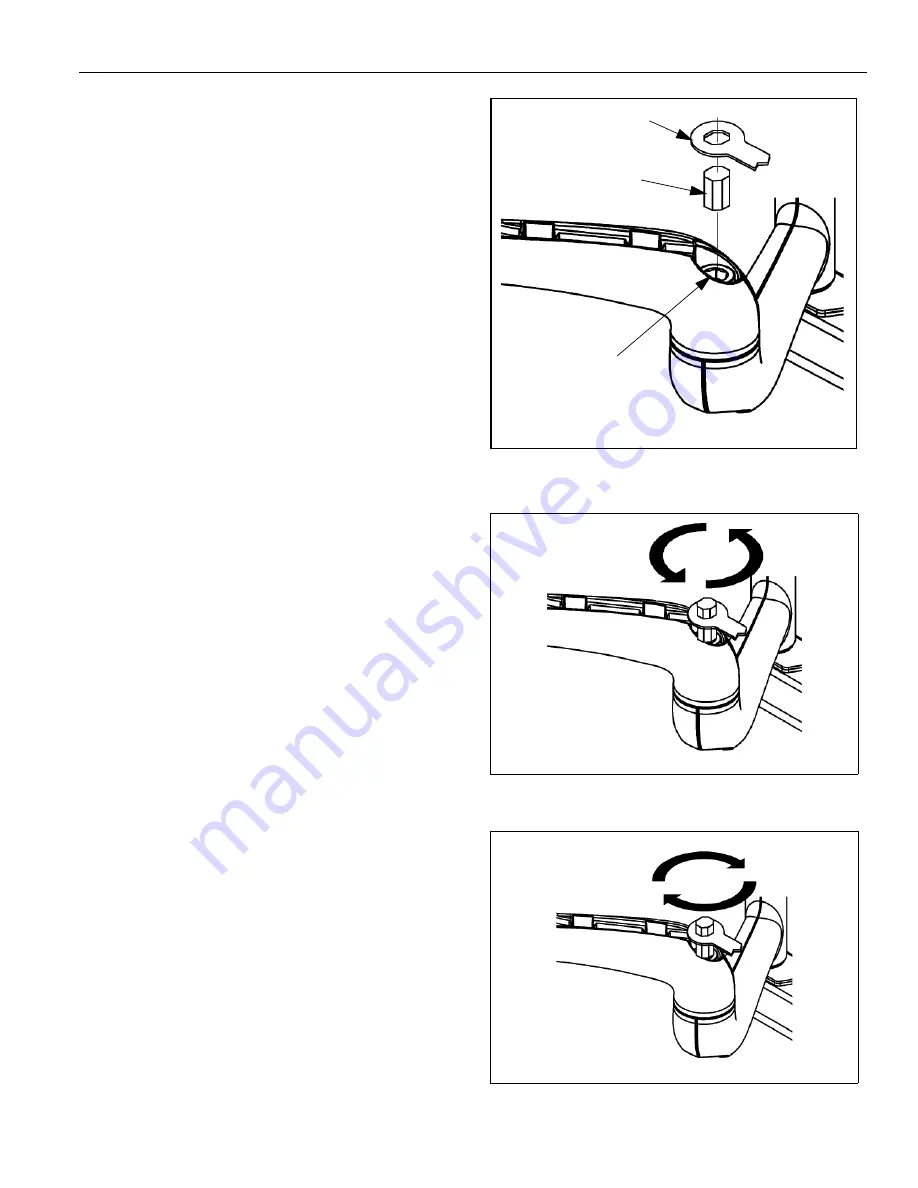

Swing Arm Tension Adjustment

Swing arm tension is pre-set at the factory and is

adjusted to accommodate displays with weights near the

top of the mounts capacity.

If smaller displays are used it may be difficult to

reposition the display after mounting. Swing arm tension

can be adjusted to compensate for smaller display by:

NOTE:

The display must be mounted prior to adjusting

swing arm tension.

1.

Locate the ajustment bar and wrench provided with

the mount.

2.

Place adjustment bar into socket head cap screw

located at swing arm pivot point. (See figure 15)

NOTE:

The display may need to be repositioned in order

to gain access to the tension adjustment

screw(s).

3.

Using the wrench provided with the mount, turn

adjustment bar clockwise to increase swing arm

tension or counterclockwise to reduce swing arm

tension. (See figure 16) and (See figure 17)

NOTE:

Small adjustments of 1/8 turn or less are typically

all that is required to achieve desired tension.

4.

Check swing arm tension. If desired tension is

present, tension adjustment is complete. If additional

tension adjustment is required, repeat steps 2 and 3

until desired tension is achieved.

NOTE:

If changing from a smaller display to a larger

displait may be necessary to increase swing Arm

tension.

Figure 15: Pivot Arm Tension Adjustment Location

Figure 16: Reduce Swing Arm Tension

Figure 17: Increase Swing Arm Tension

Adjustment

Bar

Wrench

Socket Head

Capscrew

Reduce

Increase