Installation Instructions

Model MSP-SPWH (PWH™)

5

INSTALLATION

WARNING:

Improper installation can result in serious

personal injury!

WARNING:

It is the responsibility of the installer to

verify that the wall to which the mount is anchored will

safely support five times the combined load of all

attached components and equipment. If not, reinforce

the structure before installing the mount.

Locate Single Wood Stud

1.

Determine the exact mounting location prior to

installation, considering screen size and the unit’s

total swing arm radius. Keep in mind that the pilot

holes must be drilled in the center of a wood stud or

other supporting framework.

NOTE:

Install the mount on a single wall stud or other

supporting framework that is vertical or

horizontal.

2.

Using a stud sensor, locate the wood stud where you

will mount the mount (see figure 1).

3.

Draw a level line to indicate the desired height of the

top mounting bracket.

4.

With an assistant, lift and hold the mount against wall.

NOTE:

The mount can be fastened to the wall stud using

any parallel set of mounting holes on the top and

bottom brackets.

5.

Select the mounting holes on the top bracket and

bottom where the lag bolt will be installed (see figure

2). Use a pencil, awl, or small nail to mark the

mounting hole where the pilot hole will be drilled into

the center of the wood stud.

6.

With an assistant, lay the mount down on the floor.

7.

Drill two pilot holes where the mounting holes were

marked for anchoring the mount (see figure 1).

a. If you use 5/16” lag bolts (not included), use a 7/

32” drill bit.

b. If you use 3/8” lag bolts (not included), use a 9/32”

drill bit.

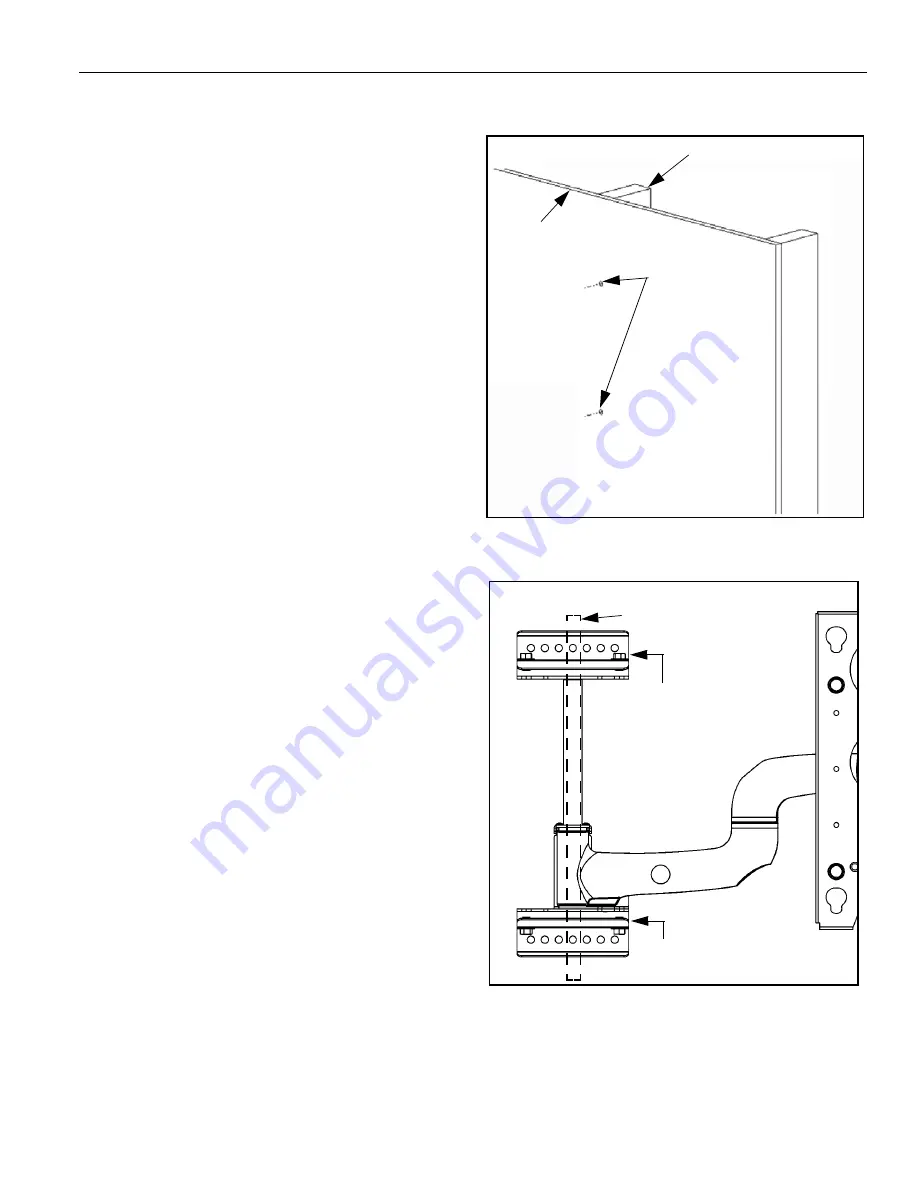

Figure 1: Single Wood Stud

Figure 2: Select Parallel Mounting Holes

Wood Stud

Pilots Holes

Wall

Select mounting hole

Select the same mounting hole

on bottom bracket.

on top bracket.

Example:

Parallel set of mounting holes.