8

Instruction Manual

SMART-LIFT 236 Electric Ceiling Lifts

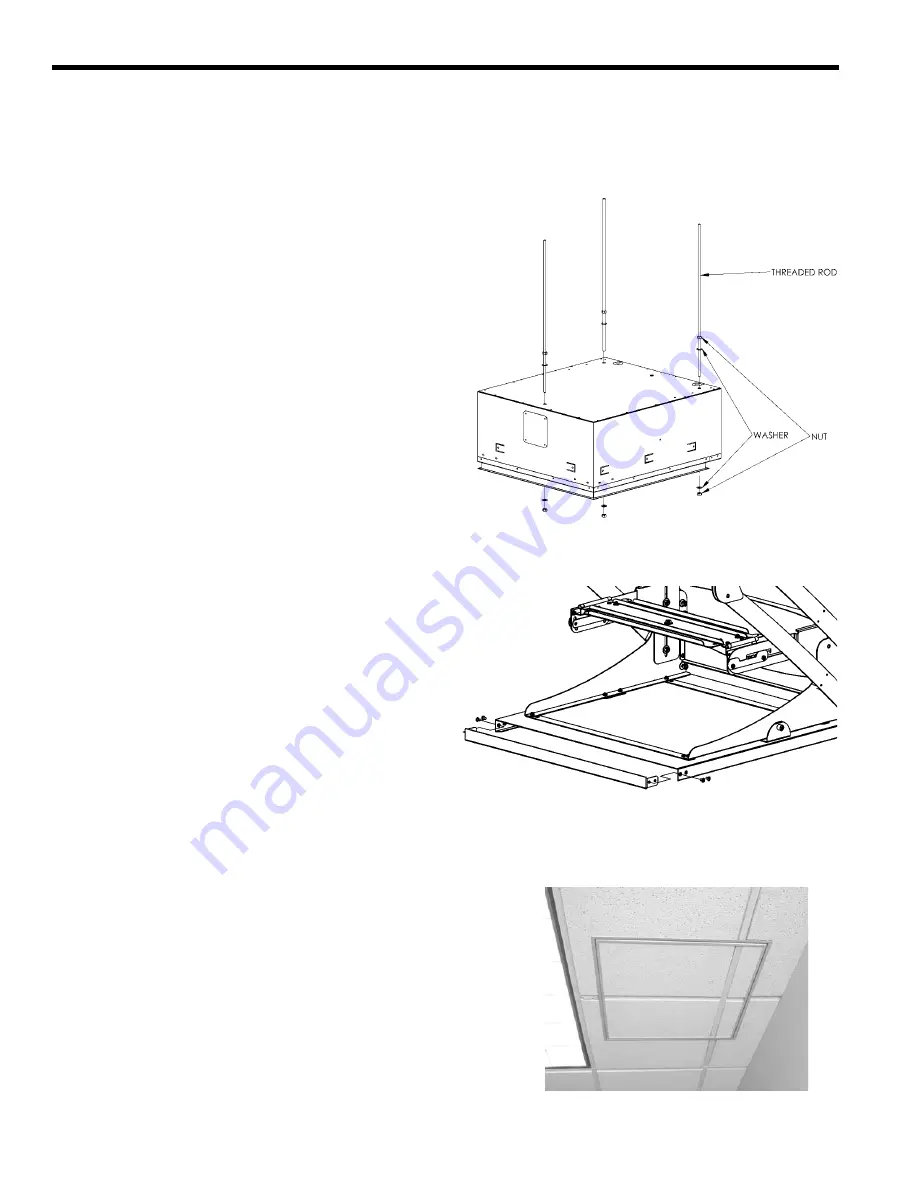

Installation in a Suspended Ceiling (using threaded rods)

You can suspend the lift housing from three 3/8-in.-dia. threaded

rods (not supplied by Chief Manufacturing) First, secure the rods to

a structural cross brace in the ceiling. Insert the rods through the

three holes on the top side of the lift housing, or through the holes

of optional brackets SMA-651, and secure them to the housing

using two jam nuts (one inside, one outside). See Fig. 3.

CAUTION: For smooth and reliable operation, the lift must be

installed square and parallel in all dimensions. Avoid stressing

or twisting the lift at any time during installation.

Install the lift using threaded rods:

1.

With the lift in the fully retracted position, remove the closure

panel from the bottom of the lift.

2.

If you are using the SMA-651, install it now.

3.

Insert the 3 threaded rods through the top of the lift or

SMA-651.

4.

Using nuts and washers, secure the lift to the threaded rods.

Finish the suspended ceiling:

1.

Cut the grid to fit the perimeter of the lift and insert it into the

side channel of lift (the side channel of the lift will support the

weight of the ceiling grid and tiles).

2.

If using the SMA-620, see the SMA-620 instructions and

install them now.

3.

Cut surrounding ceiling tile to appropriate size.

4.

Make sure the unit is level, square, parallel and there is no

stress applied to the box (chassis).

5.

Using the test push button, carefully operate the lift all the way

up and down to be sure the clearances are adequate. Be pre-

pared to stop the lift immediately if the lift begins to sound

labored or one side begins to travel slower.

6.

Replace surrounding ceiling tile.

7.

With lift at least partway open, remove four screws securing

ceiling tile retainer on bottom of tray (see Figure 4) and

remove ceiling tile retainer.

8.

Cut ceiling tile to fit inside ceiling tile retainer [include grid

pieces if necessary (see Figure 5)] and install ceiling tile (grid)

by sliding it into the open end of the ceiling tile retainer.

CAUTION: Make sure all parts assemble easily, without distort-

ing any parts, when installing tile in the ceiling tray. Any parts

protruding from the tray will cause damage when the unit

closes.

9.

Install ceiling tile retainer and secure using four screws.

Figure 3. Threaded Rod Installation

Figure 5. Grid Intersection

SL236 shown with ceiling tile and grid installed in

bottom panel

Figure 4. Remove Ceiling Retainer