TA500

Installation Instructions

6

4.

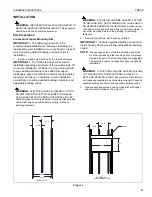

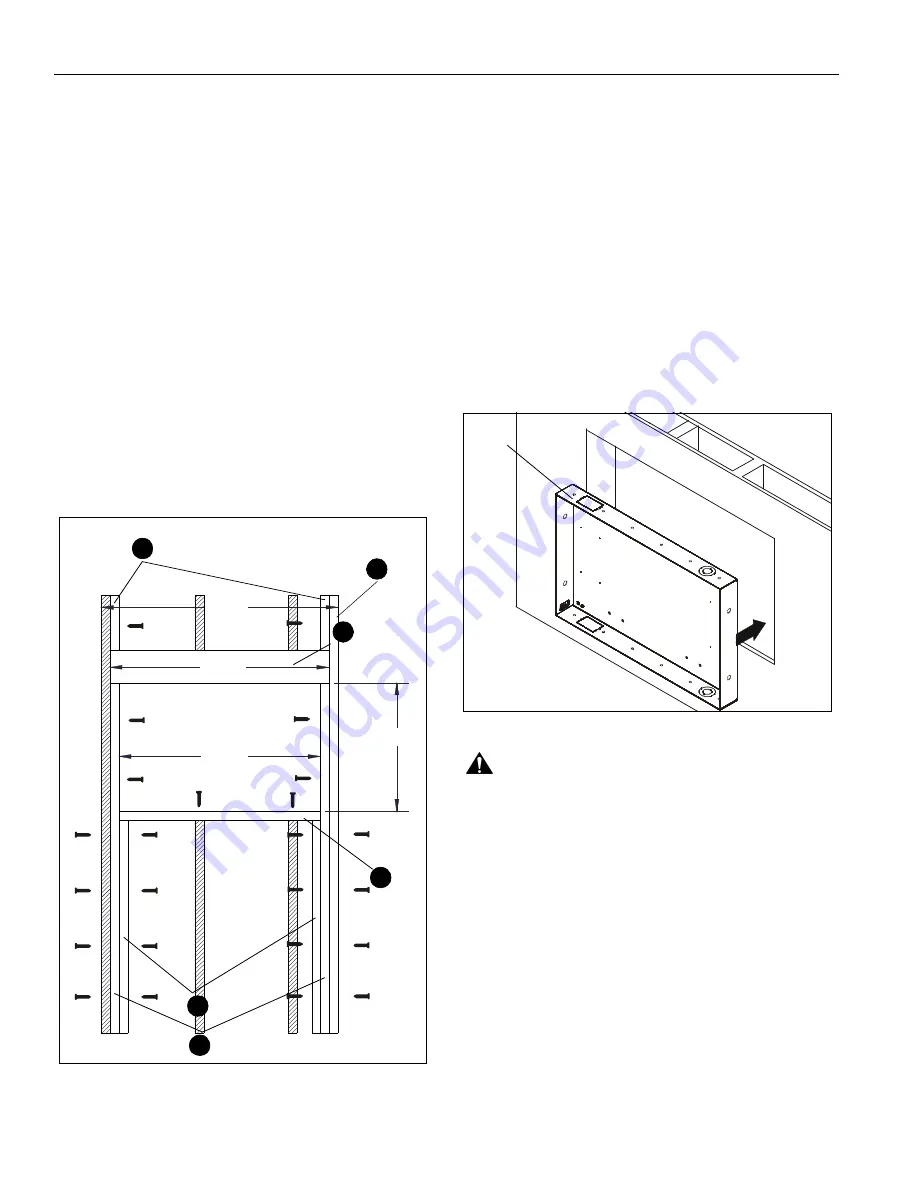

Add new stud (floor to ceiling) with outer edge 40 1/2” to the

right of left edge of far left stud. (See Figure 2)

5.

Add support framing inside far left stud and added stud from

the floor to the lower edge of header. Use #10 x 2 1/2”

countersunk wood screws (not provided) as needed to

secure. (See Figure 2)

6.

Install 2" x 6" header 37 1/2” long from inside edge of left

stud to inside edge of new stud. Use #10 x 2 1/2”

countersunk wood screws (not provided) as needed to

secure.(See Figure 2)

NOTE:

Size of header will depend on specific installation.

Consult a qualified building contractor for advice.

7.

Add support framing inside support framing added in Step 5

from the floor to the lower edge of horizontal framing. Use

#10 x 2 1/2” countersunk wood screws (not provided) as

needed to secure. (See Figure 2)

8.

Install 34 1/2” long horizontal framing inside support framing

added in Step 5. Use #10 x 2 1/2” countersunk wood screws

(not provided) as needed to secure to wood studs. (See

Figure 2)

9.

Install two blocks from top of header to ceiling along far left

stud and new stud. Use #10 x 2 1/2” countersunk wood

screws (not provided) as needed to secure to wood studs.

(See Figure 2)

Figure 2

NOTE:

Ensure screws are far enough from block end to

prevent interference with framing screws installed in

In-

Wall Enclosure Installation

section.

10. If necessary, cut rectangular hole in horizontal framing to

accommodate the PAC-GB1 Listed electrical box

accessory. (not included)

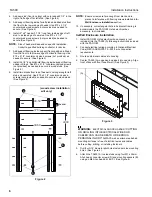

In-Wall Enclosure Installation

1.

Install PAC-GB1 Listed electrical box accessory (not

included) into the TA500 (A) following instructions included

with the PAC-GB1.

2.

Connect electrical wiring according to National Electrical

Code (NEC) ANSI/NFPA 70 - 2008, wire connection

requirements.

3.

Route audio/visual cables into housing.

4.

Center TA500 (A) in opening and insert into opening. Align

front of box with front face of wall. (See Figure 3)

Figure 3

WARNING:

ELECTRICAL SHOCK HAZARD!

CUTTING

OR DRILLING INTO ELECTRICAL WIRES OR

CABLES CAN CAUSE DEATH OR SERIOUS

PERSONAL INJURY!

ALWAYS make certain area behind

mounting surfaces is free of electrical wires and cables

before cutting, drilling, or installing fasteners.

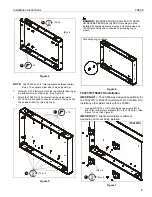

5.

Drill four 3/16” diameter pilot holes in studs at side mounting

holes. (See Figure 4)

6.

Attach the TA500 (A) to side studs using four M7 x 50mm

Allen head connector screws (D) and mounting spacers (B)

using an M4 Allen head drill bit (F). (See Figure 4)

34.50

22.00

40.50

37.50

4

5

header

6

7

8

(wood screw installation

will vary)

9

Mounting

(A)