Chapter 5

Maintenance

and Checkup

CMN003-006

原本

(Original instructions)

49

Chapter 5

Maintenance and Checkup

CAUTION

•

Before starting maintenance and checkup, be sure to break the electrical

circuit by turning off the power supply and disconnecting the plug from the

power outlet.

5.1

Replacing Filters

If clogging occurs, a “WARN2” warning appears. Replace the primary filter.

If “WARN2” remains displayed after replacing the primary filter, replace the secondary filter.

5.1.1

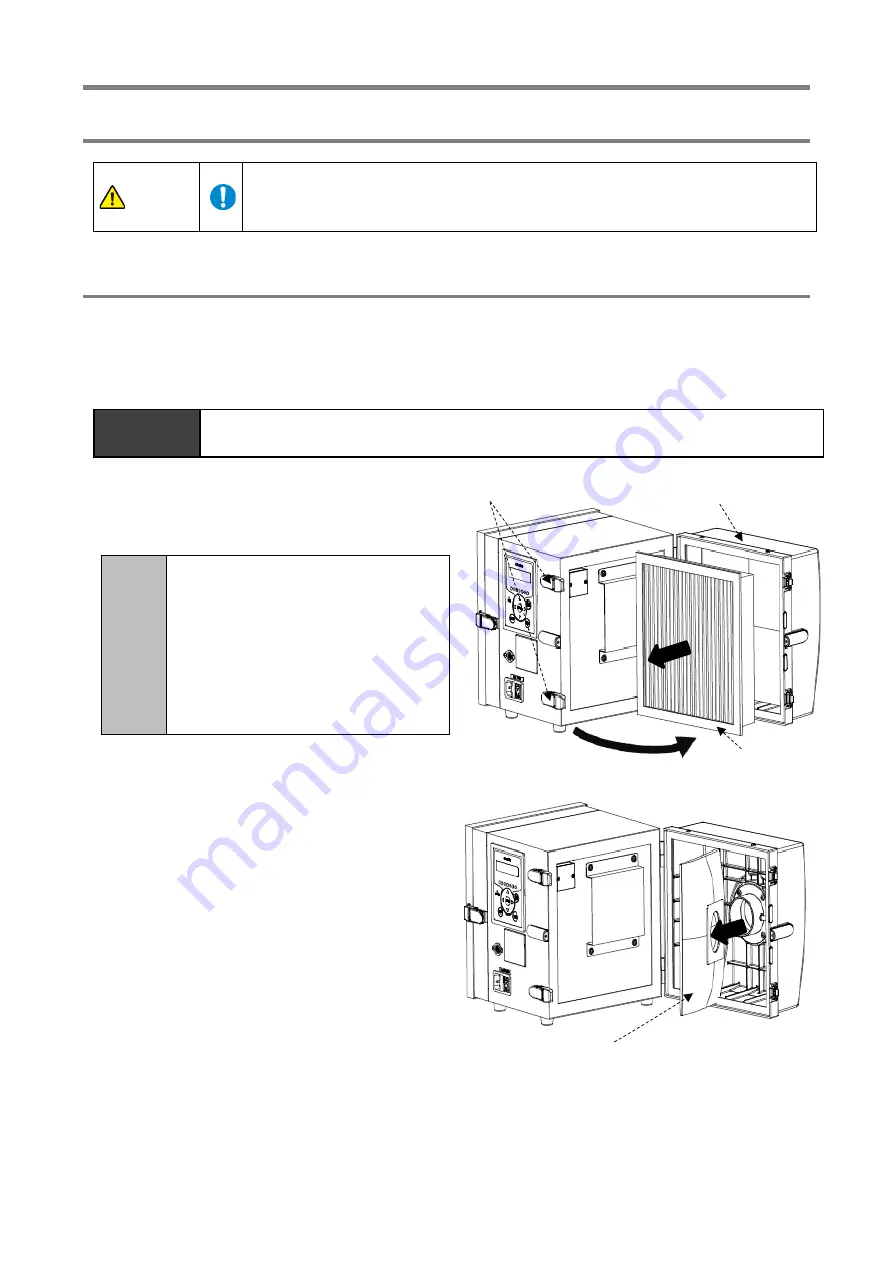

Replacing the Primary Filter

IMPORTANT

•

The primary filter should be replaced in an area large enough to open the suction-

side filter case.

1.

Release the two snap locks for suction-side

filter case.

2.

Open the suction-side filter case and remove

the secondary filter.

Note

•

If the secondary filter is hard to

remove, use a flathead

screwdriver, inserting the

screwdriver into the space (right or

left) between the suction-side filter

case and the secondary filter.

•

If necessary, the suction-side filter

case can be removed from the

device body.

3.

Remove the primary filter.

The primary filter has its filter paper packing

inserted in the flange on the filter case.

4.

Install a new primary filter and put the secondary filter back in place.

5.

Close the suction-side filter case and secure it with the two snap locks.

Snap

locks

Secondary

filter

Primary filter

Suction-side filter case

Summary of Contents for CKU-080AT3-HC

Page 6: ...1 4 1 4 2 OFF 1 5...

Page 7: ...1 CMN003 006 Translation of the original instructions 5 1 6...

Page 12: ...2 10 2 4 3 OP kPa SP kPa DP kPa EP kPa Blower Motor rpm Runtime h 16 Total h...

Page 14: ...3 12 3 1 2 10 1 2 1 2 3 2 1 ON RS485 ID 2 AT3 ON 3 4 1 7 3 ON OFF 3 30 ON OFF Ver ID...

Page 20: ...5 18 5 1 2 CKU 450AT3 HC 1 1 2 1 3 1 4 2 5 2...

Page 26: ...5 24 5 7 EL ON ON 5 2 20 1 2 3 4 1 4 ON OFF 30 1 2 1 2 5 1 17 5 1 17 5 1 17 5 1 17...

Page 27: ...6 CMN003 006 Translation of the original instructions 25 6 6 1 6 1 1...

Page 28: ...6 26 1 5V 0 2V DC 1 2...

Page 32: ...7 30 7 3 7 3 1 CKU 080AT3 HC 7 3 2 CKU 240AT3 HC CKU 450AT3 HC...

Page 33: ...CMN003 006 Translation of the original instructions 31 12 7 2 7 2 29...

Page 34: ...32...

Page 66: ...MEMO...