チコーエアーテック株式会社

Copyright CHIKO AIRTEC CO., LTD. 2011

10

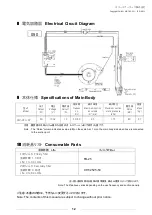

5.4

ヒューズ

Fuse

6

66

6

日常点検

日常点検

日常点検

日常点検

Daily inspection

内部機器

内部機器

内部機器

内部機器のトラブルによる

のトラブルによる

のトラブルによる

のトラブルによる過電流

過電流

過電流

過電流で

で

で

で、

、

、

、

ヒューズが

ヒューズが

ヒューズが

ヒューズが切

切

切

切れた

れた

れた

れた時

時

時

時には

には

には

には、

、

、

、ヒューズを

ヒューズを

ヒューズを

ヒューズを交換

交換

交換

交換して

して

して

して下

下

下

下さい

さい

さい

さい。

。

。

。(

((

(内部基板

内部基板

内部基板

内部基板5

5

5

5A

A

A

A)

))

)

When the fuse is blown by excessive current generated by a trouble

in the internal equipment, replace it.

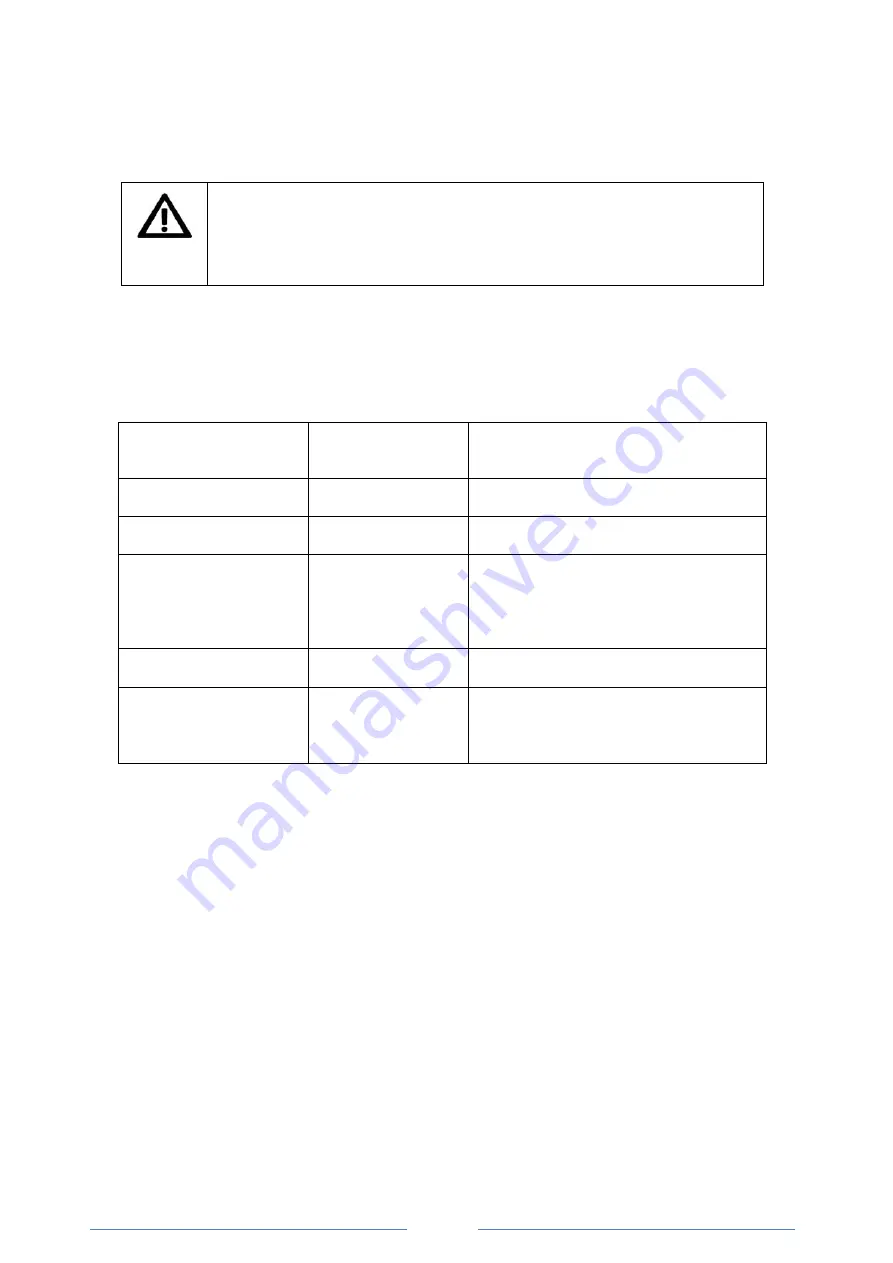

点検項目

Inspection item

頻度

Frequency

点検内容

Description

フィルタケース

Filter case

運転前

Before operation

完全に閉じているか

Is the case closed completely?

排気の状態

Exhaust status

1回/日

Once/day

排気口が閉ざされていないか

Is the exhaust port unclogged?

本体の振動

Vibrations of main body

1回/日

Once/day

異常振動、異常音がないか

設置レベルは出ているか

Are no abnormal vibrations or sounds

generated?

Is the installation level correct?

フィルタの取り付け状態

Filter installation status

1回/月

Once/month

フィルタ取り付けが緩んでいないか

Are the filters installed securely?

フィルタ目づまり状態

(吸引力確認)

Filter clogged status

(Suction force check)

運転時

During operation

吸込みホース端の吸引力は適切か

Does the suction hose end offer proper

suction force?