チコーエアーテック株式会社

Copyright CHIKO AIRTEC CO., LTD. 2009

17

8

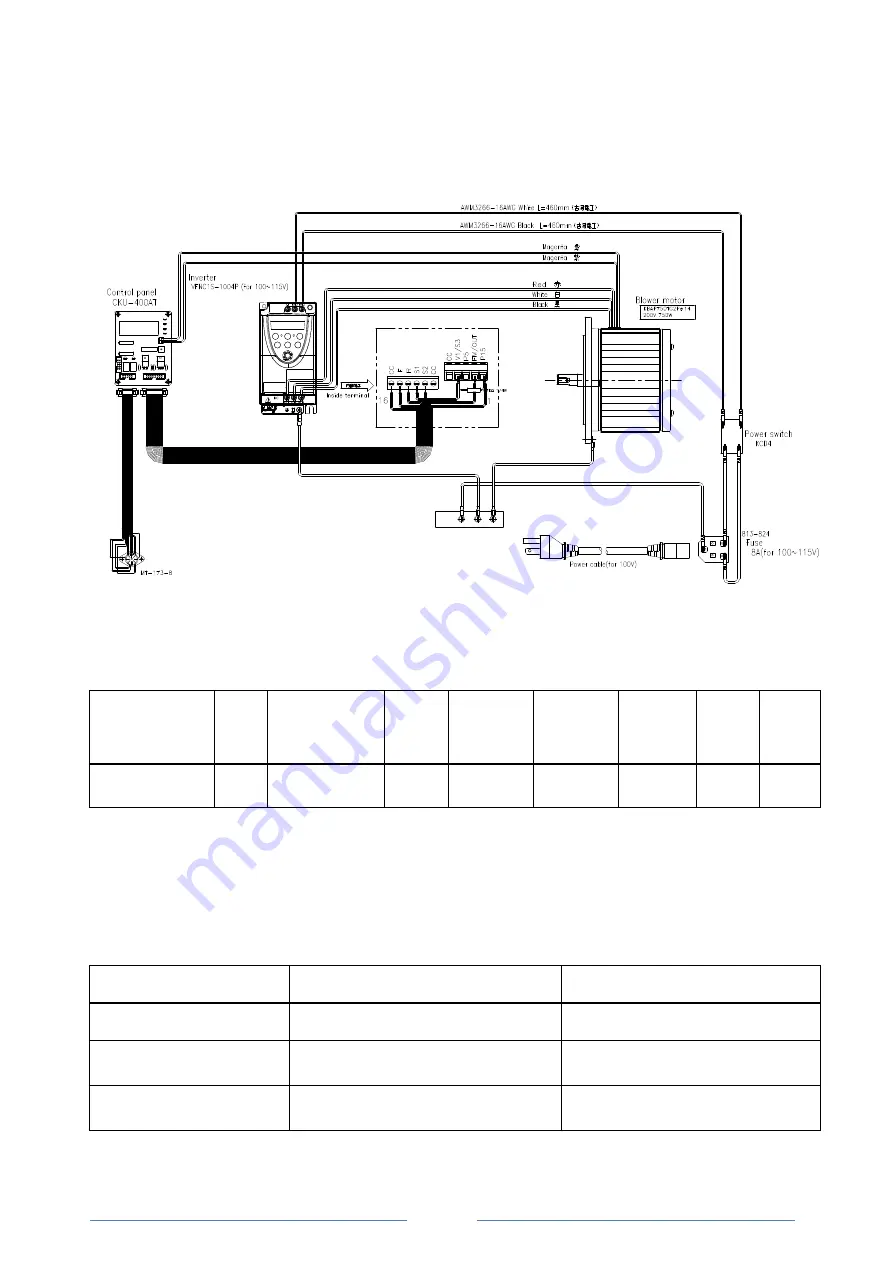

電気回路図

Electrical Circuit Diagram

9

本体仕様

Specifications of Main Body

型式

Model

出力

Output

(KW)

電圧

Voltage

(V)

電流値

Current

(A)

周波数

Frequency

(Hz)

吸込風量

Suction air

volume

(m

3

/min)

吸込静圧

Suction static

pressure

(kPa)

騒音値

Noise

(dB)

質量

Mass

(kg)

CKU-400AT-HC-V1

450

100V

単相

Single-phase

8.2

50/60

7

2.85

73

40

注

)

騒音値は吸込み口にホースを接続し、本体機側

1

m Aスケール

dB

で表しています。

Note:

The “Noise” column indicates a value (dB) on the scale A at 1 m on the main body side when the hose is

connected to the suction port.

10

消耗品リスト

Consumable Parts List

消耗年数

Life

フィルタ型式

Model

1

次フィルタ

Primary filter

1-3

カ月

3 to 6 months

FB-40

2次フィルタ

Secondary filter

3-6

ヶ月

3 to 6 months

CHF-3535-70

排気フィルタ

Exhaust filter

3-12

カ月

3 to 12 months

HEP-3535-69

注)上記消耗年数はお客様の使用頻度、吸い込み濃度によって変わります。

Note: The life above varies depending on the use frequency and suction density.