30

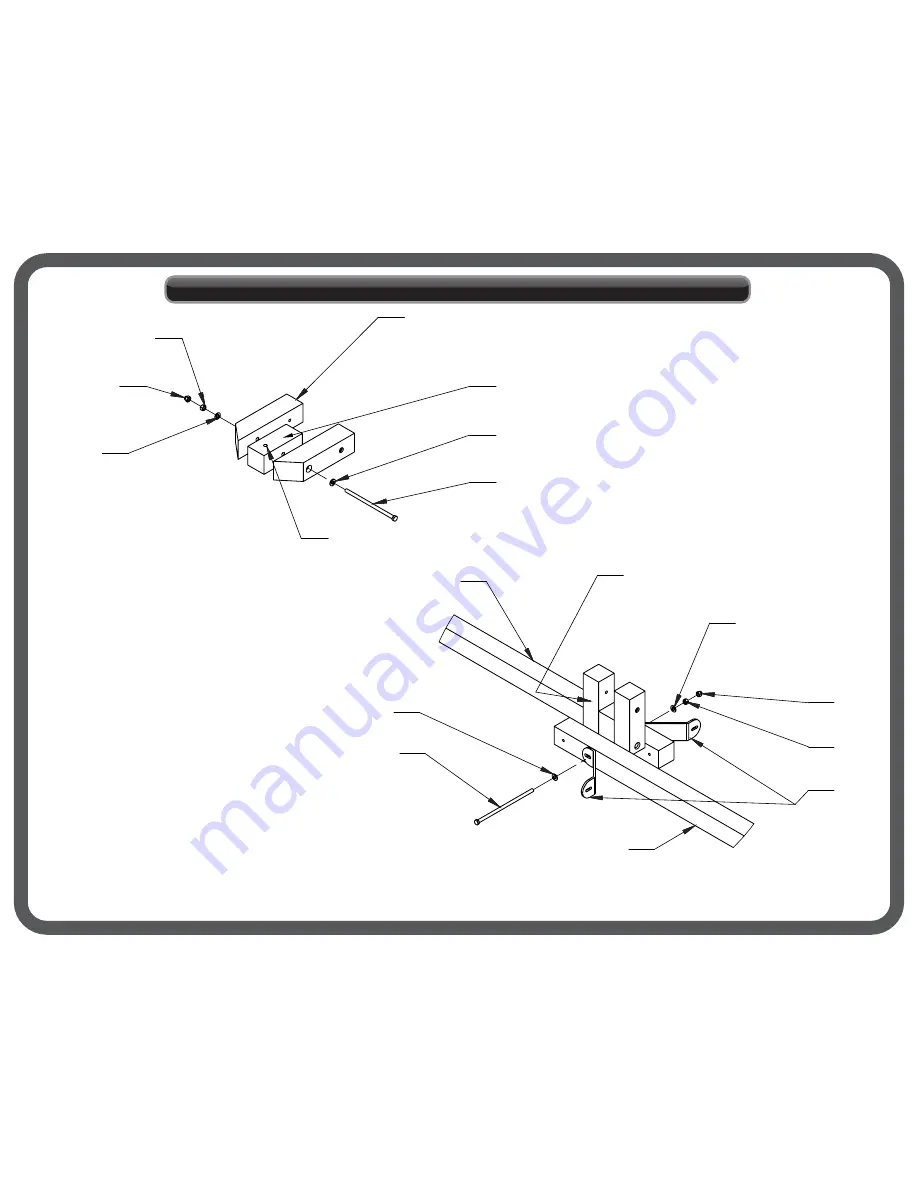

U - S H A P E D B R A C K E T - A S S E M B L Y

1. Arrange U-Shaped Bracket using item #70, and

2. Using hardware items #73, #74, #75, and #76

3. Lay items #67 on flat surface as shown.

4. Arrange U shaped Bracket Assembly and items #67 as shown.

5. Bolt item #66, U Shaped Bracket Assembly, and Items #67 together as shown.

Using hardware items #73, #74, #76, and #77.

DO NOT TIGHTEN HARDWARE AT THIS TIME

#69 as shown.

assemble U-Shaped Bracket.

#69

#73

#76

#74

#74

#75

POSITION LOWER HOLE AS SHOWN

#70

#77

#74

#67

#67

#74

#76

#73

#66

U -SHAPED BRACKET ASSEMBLY

PARTS NEEDED

#66

ANGLE BRACKET

(2)

#67

118” A-FRAME LEG

(2)

#69

U-JOINT CENTER SPACE BLOCK

(1)

#70

U-JOINT OUTSIDE

(1)

HARDWARE

NEEDED

#73

½”-13 ACORN NUT

(2)

#74

½” FLAT WASHER

(4)

#75

½”-13 X 10” HEX BOLT

(1)

#76

½”-13 NYLON LOCKNUT

(1)

#77

½”-13 X 11.5” HEX BOLT

(1)