4

CAUTION: FAILURE TO ABIDE BY ABOVE PROCEDURE MAY INCUR PHYSICAL DAMAGE TO THE CHILLER’S

COMPRESSOR.

TO PROPERLY DISPOSE OF YOUR CHILLER - Your old Chiller may have used a regulated refrigerant in its cooling

system. These refrigerants are believed to harm stratospheric ozone. If you are throwing away your old Chiller,

make sure the refrigerant is removed and recovered for proper disposal by an EPA-certified technician. If you

intentionally release this refrigerant, you can be subject to fines and imprisonment under provisions of

environmental legislation.

7.

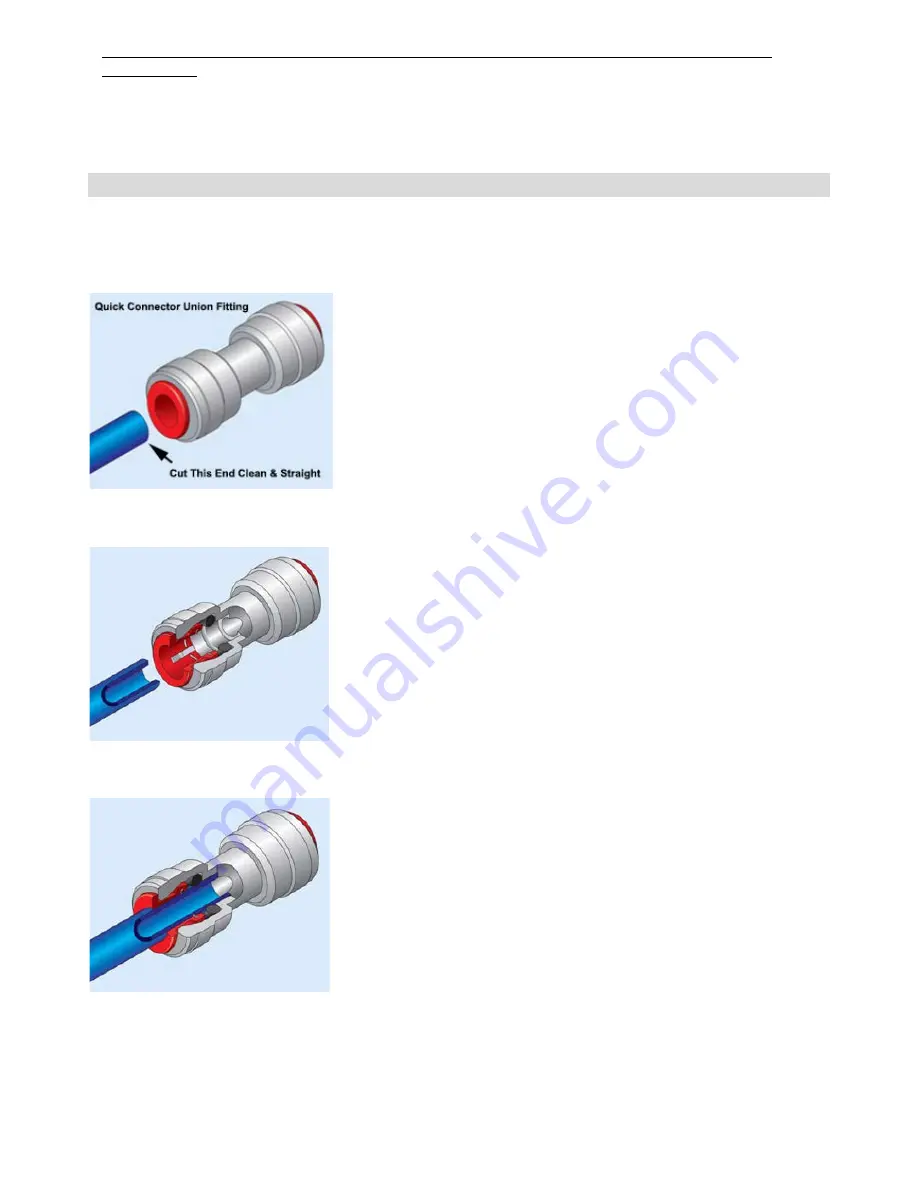

QUICK CONNECTOR UNION FITTINGS

¼” x ¼”

First you must remove the temporary “Connector Plugs” from the water Inlet and Outlet ports of the Quick

Connector Unions when installing the Chiller. See Step # 4 below for Tube & Plug removal instructions for Quick

Connector fittings.

Step 1. Cutting the Tube

•

Cut the end of the tube to be inserted

into the fitting to make the end of the

tube be a smooth and straight cut.

•

Make sure to start with a clean tube

without any foreign material, free of

score marks and scratches.

•

Use a utility knife with a fresh blade or

Tube Cutter. Do NOT use a hacksaw.

Step 2. Inserting the Tube

•

When inserting the tube, remove any obstructions inside of the

fitting before inserting the tube. Push the tube firmly into the

quick connect fitting to ensure that the tube is fully connected

and sealed. Inserting the tube into the fitting only takes

moderate force.

•

To avoid damage to the O-Ring, make sure burrs and sharp

edges are removed from the cut end of the tube. The tube, O-

Ring or fitting should not be scratched or damaged as this can

cause water leaks later on.

•

The collet clip (gripper) (see Step 4 drawing) has stainless steel

teeth which permanently hold the tube firmly in position while

the O-Ring provides a leak proof seal.

•

For soft or thin walled plastic tube other than standard poly

tube we recommend the use of a tube insert to prevent the

tube from collapsing & leaking.

Step 3. Checking the Connection

•

To check that the fitting is properly connected to the tube, pull

it moderately once. The tube should not be able to be pulled

out of the fitting.