•

the unit must not be installed in a room where recirculation air can bring such

substances to the inlet opening of the unit that block air circulation (for

instance greases from the kitchen).

•

the installation and maintenance room required for electrical installations,

pipe-laying, and installation of sewerage for condensation water.

Table 1: Limitations for the GIANT installation site

Temperatures

Min.

Max.

Indoor air

5 °C

(A)

32 °C

Water

4 °C

(B)

80 °C

(C)

Ethyl alcohol (35%)

4 °C

80 °C

Ethylene glycol (35%)

4 °C

80 °C

Propylene glycol (35%)

4 °C

80 °C

Notes.

A

If the room temperature is below 0 °C, the unit must be drained of water and the

condensation water must be removed.

B

For lower temperatures, using anti-freeze agent is imperative.

C

The maximum water pressure is 1000 kPa/10 bar.

You can find the main dimensions of the unit in

Section 3.2 Unit dimensions

4.3

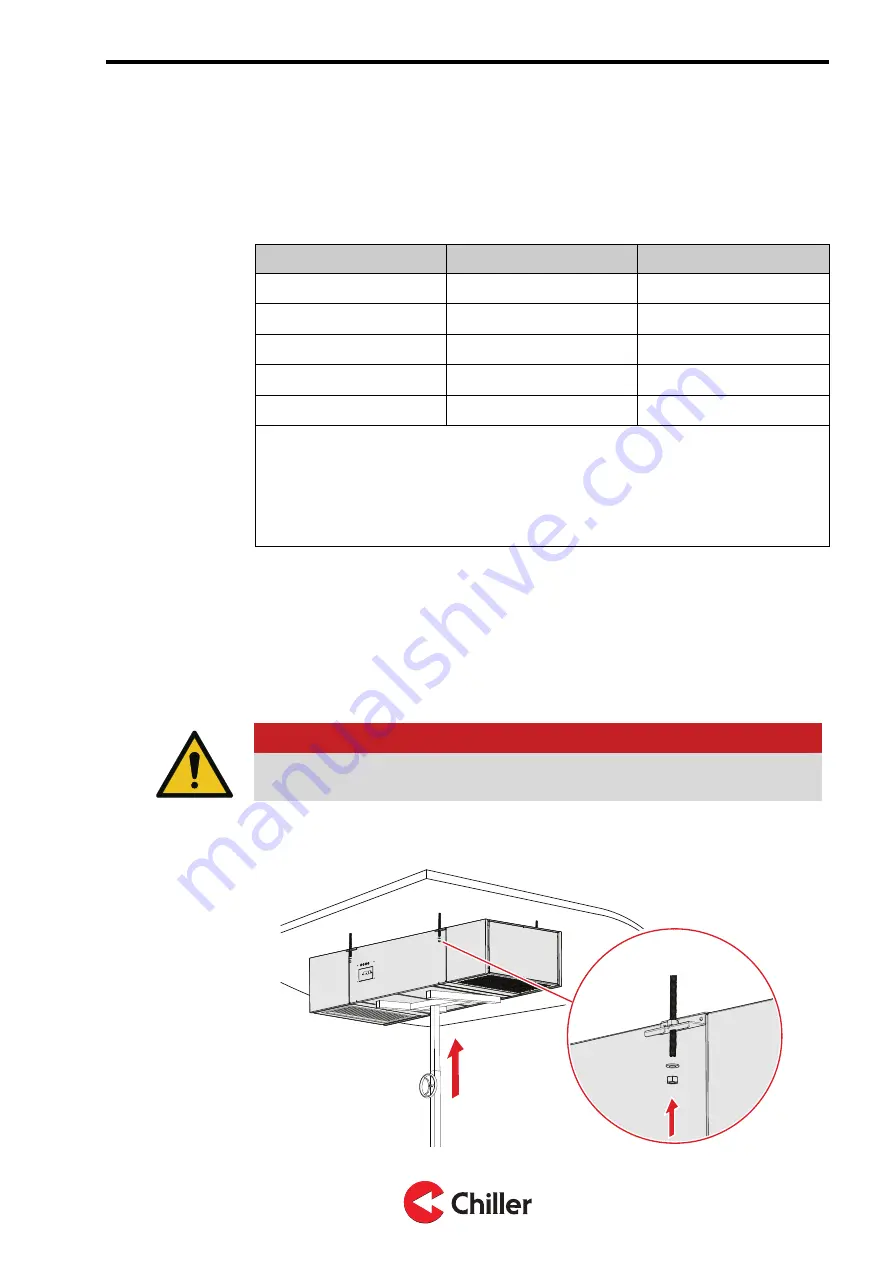

Mounting the unit to the ceiling

The unit is mounted to the ceiling from four (4) mounting points. The mounting points

are integrated in the unit frame. Use M8 fasteners, when you mount the unit to the

ceiling.

DANGER

Risk of severe injury. Make sure you attach the unit firmly to the ceiling. If the

unit is not properly attached, it can fall and cause severe injury.

1. Install the unit to the ceiling from the four (4) mounting points.

16 (40)

Copyright © 2020. All rights reserved.

GIANT Vari – Installation, Operation, and Maintenance Manual

N02541445 Rev. A