User Guide

5

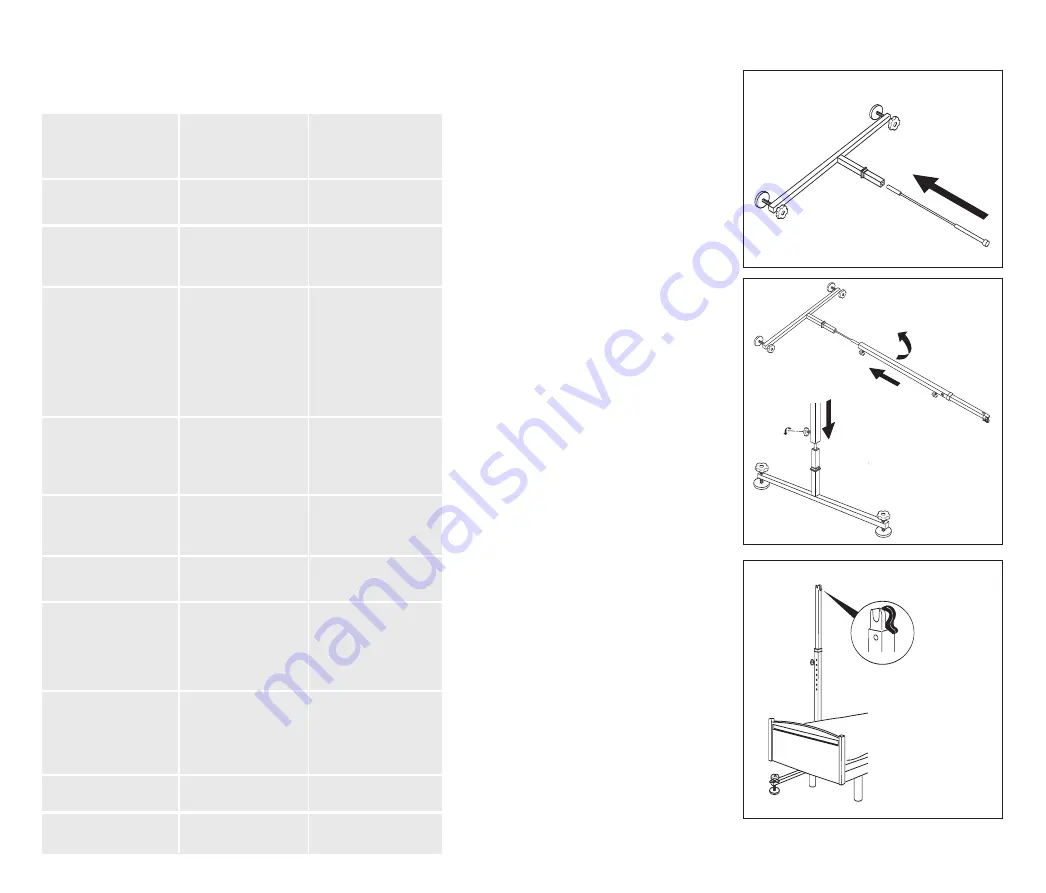

3. Locating the leg

and foot sections

and inserting the

gas strut

Where there is limited

head room it is

recommended that

the foot section is

laid on its side for

assembly as Fig 3.

Insert the gas strut in

the orientation shown

in Fig 3.

Place the leg section

over the gas strut as

Fig 3 (B)

(Note:

Orientate the leg to

ensure the top catch

bracket is pointing

towards the floor),

while raising the leg

at the same time

(taking care not to

damage the gas

strut), compressing

the gas strut and

pushing down as far

as the moulding on

the foot section as

Fig 3 (C).

Note: The

bottom handwheel

needs to be almost

all the way out.

4. The top catch

bracket should be

located on the inside

as Fig 4. Tighten the

lower handwheel to

secure in place.

Safety note: The

leg is not yet free

standing. Do not

leave the leg

unattended. Lay it

on the floor, against

a bed or wall.

Repeat for other leg.

Fig 3

Fig 4

Top catch bracket on

leg section facing inward

B

A

Fig 3B

Fig 3C

Chiltern Invadex LiteTrack Portable Gantry

16

symptom

suggested cause

solution

Troubleshooting

Cassette travels

further in one direction

along the beam than

the other

Pins do not click into

position on the leg

Pins do not click into

position on the end

beam/cassette

Spring mechanism is

stuck on the leg/end

beam section

Spring mechanism has

failed on the leg/end

beam section and will

not push in manually

Height of feet cannot

be adjusted

Cannot check gantry is

level

Lifting eye on cassette

will not come down

Corner quadrant will

not fold back against

the leg

There is no tension in

the corner quadrant

Leg does not raise

easily/falls under gravity

Gas strut will not

compress

Cable tension is

incorrect

Leg section is

incorrectly positioned

End beam section is

incorrectly positioned

Push pin in manually

Spring mechanism is

damaged

Thread on feet is

damaged or twisted

Spirit levels are

damaged or broken

Spring mechanism is

defective/damaged

Gantry leg not positioned

correctly to accept the

corner quadrant.

Corner quadrant is

defective/damaged

Washers in the corner

quadrant are damaged/

defective.

Adjust grub screws

Gas strut is damaged

Gas strut is damaged

Contact Chiltern

Invadex for assistance

Adjust leg position

Adjust end beam

position

If problem persists

contact Chiltern

Invadex for assistance

Contact Chiltern

Invadex for assistance

See replacement parts

list in this booklet.

Contact Chiltern

Invadex for parts.

Contact Chiltern

Invadex for

replacement parts.

Contact Chiltern

Invadex for assistance

Reposition gantry leg

at 90 degrees.

Contact Chiltern

Invadex for assistance

Contact Chiltern

Invadex for assistance.

Check tension

Contact Chiltern

Invadex for assistance

Contact Chiltern

Invadex for assistance