Chiltern Invadex LiteTrack Portable Gantry

4

Check all components are available prior to assembly.

Notes:

If the gantry is to be assembled over a bed

The gantry can be assembled over a bed

unless

it is occupied. If the

bed is occupied assemble the gantry away from the bed and then

position afterwards (as a guide this would be approximately 900mm

from the head board but

always ensure the gantry track is directly

above the clients centre of gravity

).

1. Preparation

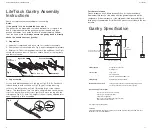

1. Unpack all components and lay on the floor ready for assembly.

2. Check all parts are available (see Fig 1) and for damaged components.

3. Safety note: The corner quadrant located on the end beam (see Fig 1)

should always have tension. Check to ensure it does not swing freely

and there is tension.

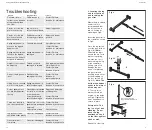

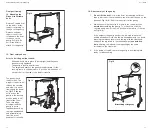

2. Leg assembly

Loosen both black handwheels on the leg as Fig 2 (C & D). Push both

release levers in with one hand as Fig 2 (A), pull out the inner leg

section to the first position as Fig 2 (B) having let go of the release

levers. This should then ‘click’ into place (the pin will be flush with the

top of the block when in the correct position). Secure the leg with the

locking knob Fig 2 (C). Note: The height of the unit can be adjusted later

when the gantry is fully assembled.

A

A

A

B

C

D

LiteTrack Gantry Assembly

Instructions

Fig 2

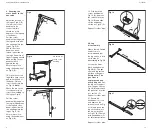

Foot section x 2

Leg section x 2

Cassette x 1

End beam x 2

Foot section x 2

Leg section x 2

Cassette x 1

Gas strut x 2

Corner

quadrant x 2

Fig 1

User Guide

17

Lifting capacity

210 Kg (33 stone)(460 lb)

including hoist

Construction

Legs - steel

Track - Aluminium

Cassette - Aluminium with ABS cover

Lifting Range

Approximately 1525mm - 1825mm

Maximum loading per foot

100kg (16 stones) (220lb) (provided that the gantry is used in

accordance with the instructions in this user guide)

Assembled component weights:

Lower Leg section (x2) 7kg each (15.5lb)

Upper Leg section 8kg each (18lb)

Cassette (x1) 11kg (24lb)

End section/corner quadrant (x2) 5kg each (11lb)

Gas strut (x2) 1kg each (2.2lb)

Total weight of gantry 53kg (116lb)

CE MARK

The Chiltern Invadex Wispa LiteTrack Gantry carries the CE mark and complies with EC Directives:

Medical Device Directive(93/42/EEC)

Further assistance

Please telephone any Chiltern Invadex Office for further assistance.

Remember that service calls made after the guarantee period will be

chargeable. If the maintenance of the equipment is the responsibility of a

third party, for example the Social Services, please contact them in the first

instance.

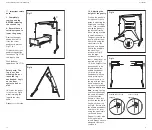

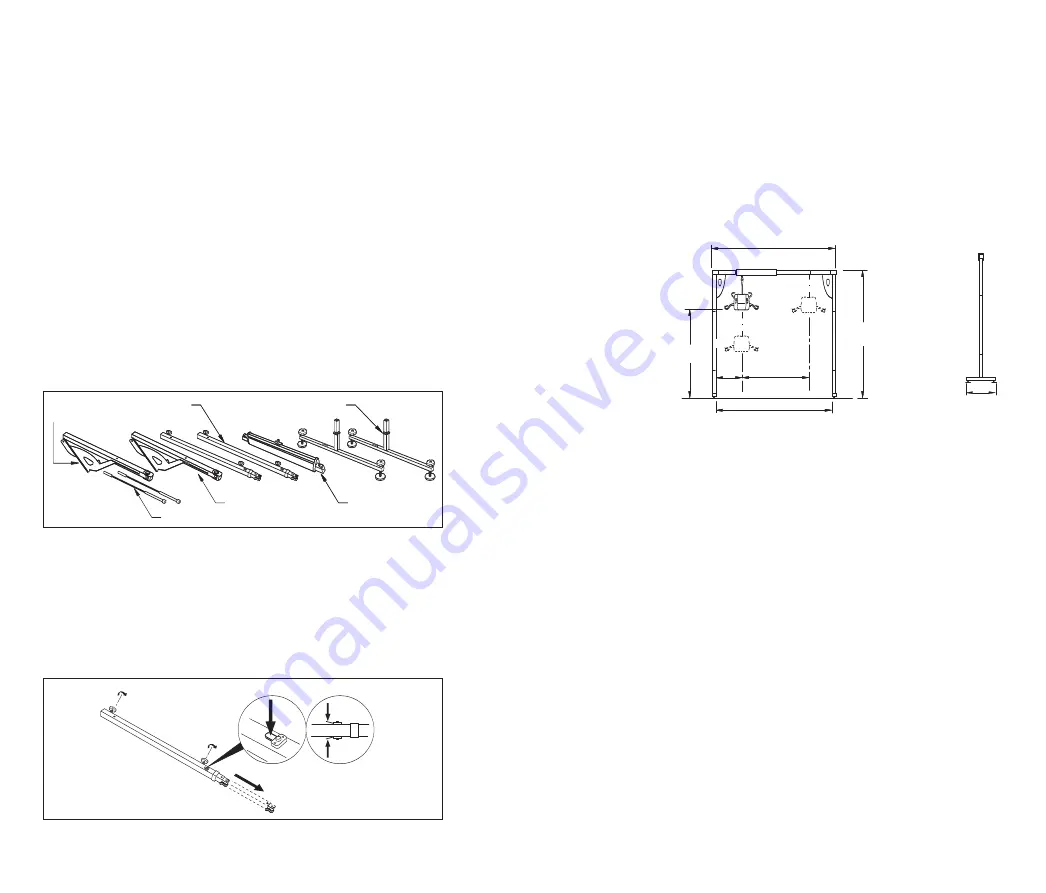

Gantry Specification

2165 - 2465

(50mm intervals)

1010 - 1530

440

Gantry at highest position 1825

Gantry at lowest position 1525

2040 - 2560

1890 - 2410 (Internal)

1100