Chiltern Invadex LiteTrack Portable Gantry

6

6. Attaching beam

to leg section

Please note prior to

assembly:

Top catch bracket on

the leg section should

be on the

inside

to

accept the beam as

Fig 6.

Top catch bracket on

leg section facing inward

Fig 6

B

A

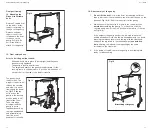

5. Assembling the

cassette and end

beams

Notes:

1. The end beams

which attach to the

cassette are identical.

2. The cassette can be

positioned either way

round.

3. Assemble the

cross beam as close

to the legs as

possible.

Rotate the corner

quadrant to the

position shown in Fig

5. Push the release

lever down with one

hand as Fig 5 (A) and

slide the end beam

into the cassette as

Fig 5 (B) having let go

of the release lever

as the end beam

begins to slide, and

select the appropriate

hole (depending on

lifting task - see p14

for Width calculation

guide). The end beam

will then ‘click’ into

place (the pin will be

flush with the top of

the block when in the

correct position).

Repeat for other side.

Fig 5

User Guide

15

Servicing and Maintenance

Based upon EN10535:1998 and Health and Safety Executive guidance

Chiltern Invadex recommend that hoists and gantry systems are fully

serviced, including a load test, at least every 12 months with an interim

six monthly inspection to LOLER requirements. Prices are available from

Chiltern Invadex Service Offices. The frequency of servicing should be

increased in areas where the environment or heavy usage may cause

deterioration of the equipment. Further details can be obtained from any

Chiltern Invadex Office, shown on the back of this booklet.

Chiltern Invadex and its Authorised Dealers are able to carry out all

aspects of servicing and maintenance work.

Maintenance of this equipment should only be conducted by engineers

trained and certified by Chiltern Invadex.

Keep the service record (at the back of this booklet) up to date.

DO NOT USE IF:

1. There is any damage to the hoist or gantry.

2. There is fraying or stitch damage to the lifting tape, or slings.

3. Any of the gantry parts are missing or damaged

To ensure maximum cleanliness

Wipe with a dry cloth (Gantry and hoist). For stubborn marks use a damp

cloth and a mild cleanser. Always read the manufacturers instructions

prior to applying the cleanser. Avoid using cleaning agents which contain

chlorine, carbolic acid or other strong chemicals as these may damage

the metalwork and plastic components.

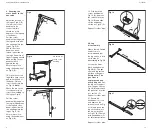

Parts

item

description

qty

part no

1

Upright mouldings kit (all mouldings for legs)

1

360-80001

2

Beam mouldings kit (all mouldings for horizontal beam)

1

360-80002

3

Hand Wheel (Black)

1

COM0081

4

Levelling Foot Kit

1

360-80011

5

Spirit Level spares kit (x4 spirit levels)

1

360-80003

6

Gas strut assembly spares kit (x1)

1

360-80004

1

4

Note: Replacement parts should only be installed by trained personnel.

The gantry then needs testing once parts have been replaced.

6

5

2

3