Chiltern Invadex LiteTrack Portable Gantry

8

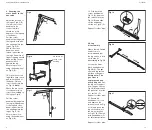

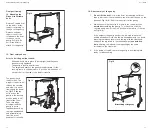

9. Securing the

cross beam to the

cassette

Adjust the position of

the leg as Fig 8.2 (B)

to allow the corner

quadrant to be

connected (this

should be at 90

degrees to the leg and

cross beam).

Pull the corner

quadrant back against

the leg and hold with

one hand against the

leg as Fig 9 (A).

Check the cross

beam has been

locked in position on

the legs. Be aware of

finger trapping hazard

when pulling corner

quadrant back

against the leg

.

Secure in position

using the handwheel

as Fig 9 (B).

Fig 9

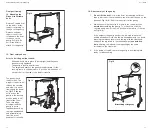

10. Place the second

leg within easy reach

and raise the end of

the beam. Place on

top of the second leg

as Fig 10.

Note:

Check the pin on the

cross beam sits on

top of the moulding on

the legs as Fig 10.

Fig 10

Pull the corner

quadrant back against

the leg (at 90 degrees

to the leg and cross

beam) and hold with

one hand against the

leg as Fig 11 (A).

Secure in position

using the handwheel

as Fig 9 (B).

Fig 11

A

B

A

Pin should sit

on top of the

moulding

User Guide

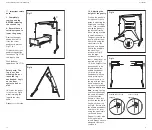

13

B

A

C

B

C

A

Fig 19

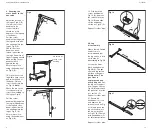

19. Fold back the

corner quadrant as

Fig 19 (A), depress

the release lever as

Fig 19 (B) and slide

out the end beam

section as Fig 19 (C).

Repeat for other side.

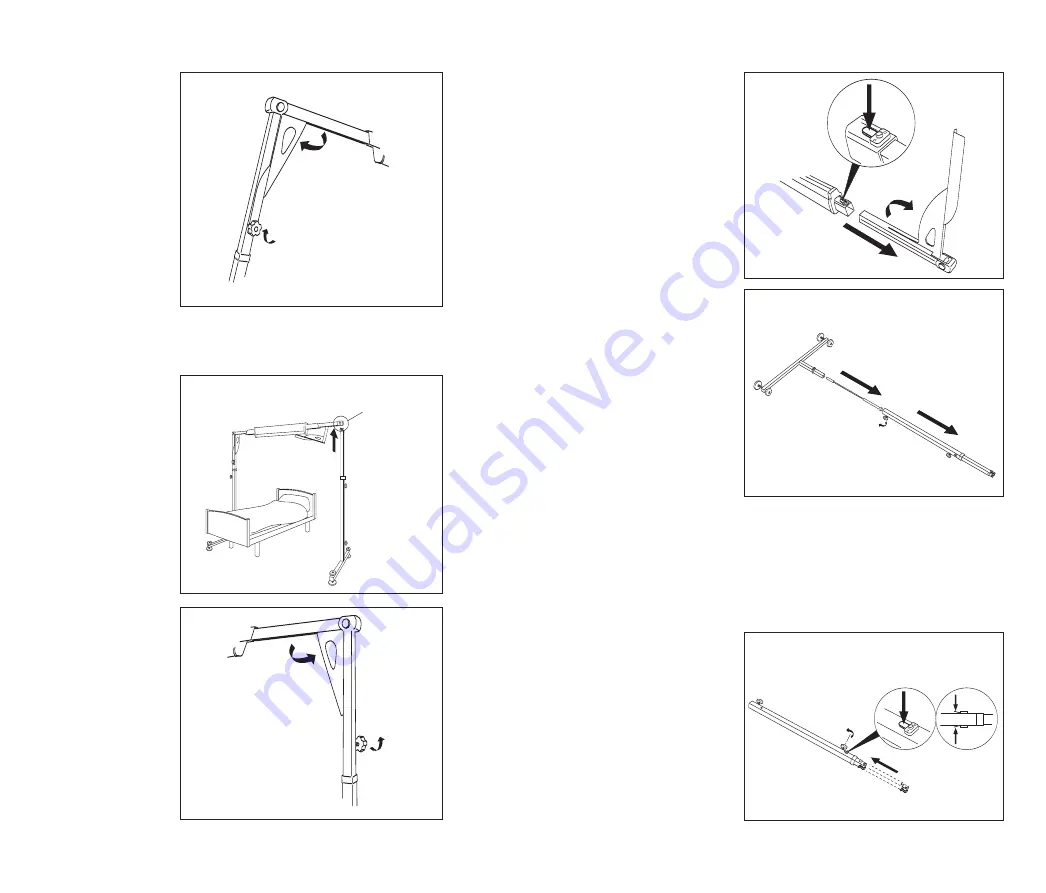

20. Leg

disassembly

Where there is limited

head room it is

recommended that

the leg section is laid

on its side for

disassembly as Fig 20.

Loosen the lower

black handwheel as

Fig 20 (A). The gas

strut and leg section

will then slide apart.

Safety note: The

gas strut is

compressed and

will spring out.

Pull

the leg section apart

from the gas strut as

Fig 20 (B) and remove

the gas strut from the

foot section (C).

Repeat for other side.

Fig 21

Fig 20

B

C

A

A

A

21. Ensure top

handwheel is loose

and depress the

release levers as Fig

21 (A) and push the

leg section down to

the lowest position

as Fig 21 (B). Fasten

both handwheels (C)

for safe transportation.

Repeat for other side.