- 78 -

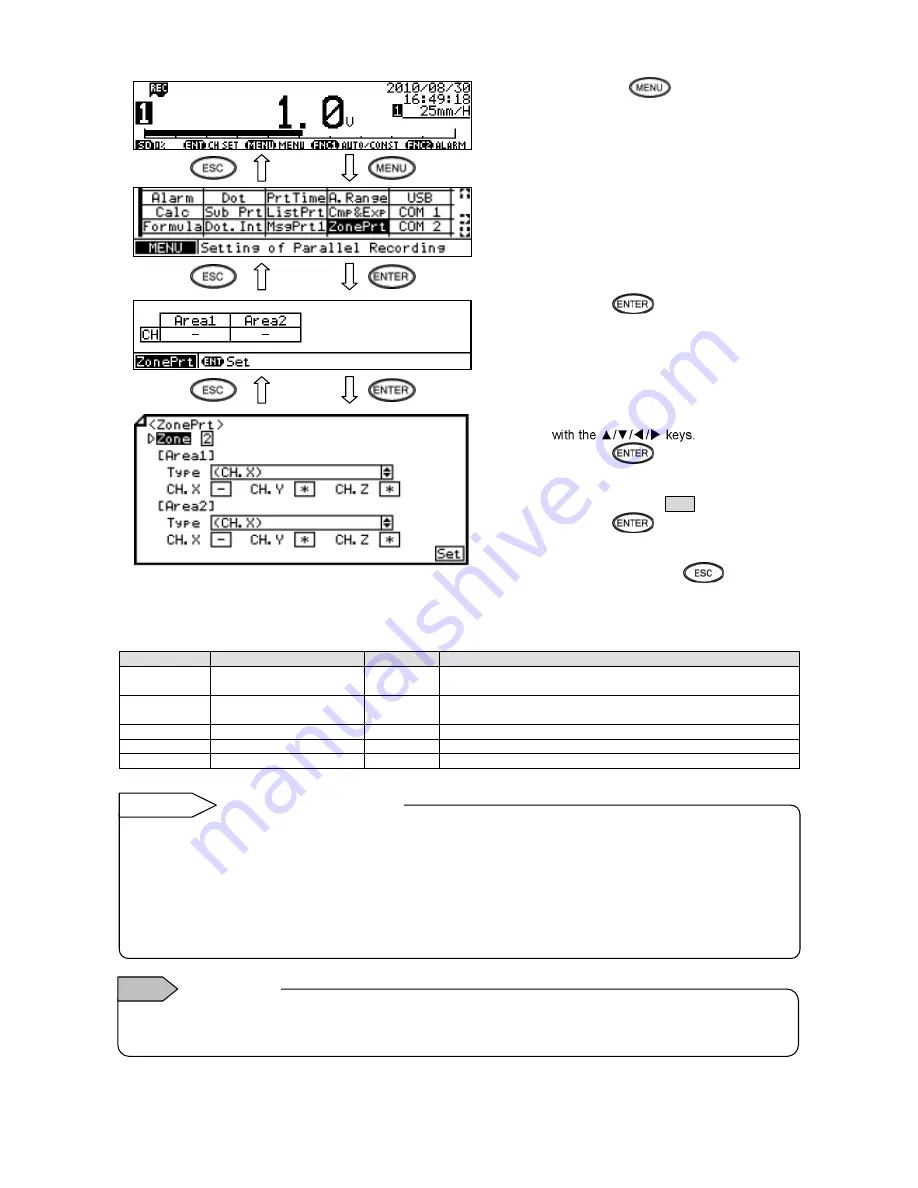

* Make sure that the recordi

ng format is set to “Zone Print (zone printing)” and then perform the following settings.

(1) Pressing the

key displays the

menu window (list of setting items).

(2) Select

“ZonePrt”.

(3) Press the

key.

(4) Move the cursor to the parameter to be set

(5) Press the

key to make it available

for setting and then select or enter a value.

(6) After completing the settings of this item,

move the cursor to Set .

(7) Press the

key to register the

settings (when chart recording is ON, a

setting change mark is printed). To cancel

the settings, press the

key.

[List of Zoneprt setting parameters]

Parameter

Function

Default

Set value

Zone

Number of divisions for

zone printing

2

Type

Area specification format

Selected from options

CH.X

CH.X, CH.X/CH.Y, CH.X - CH.Y, CH.X/CH.Y/CH.Z,

CH.X - CH.Y/CH.Z, CH.X/CH.Y - CH.Z

CH.X

-

- (Not used), 1 to 6

CH.Y

*

- (Not used), 1 to 6

CH.Z

*

- (Not used), 1 to 6

Note: Actua

l windows are separated. Use the ▲/▼ keys to

scroll and continue settings.

(CH.X) ················································· Record CH.X to the specified area.

(CH.X)/(CH.Y) ····································· Record CH.X and CH.Y to the specified area.

(CH.X) - (CH.Y) ··································· Record CH.X - CH.Y to the specified area.

(CH.X)/(CH.Y)/(CH.Z) ·························· Record CH.X, CH.Y and CH.Z to the specified area.

(CH.X) - (CH.Y)/(CH.Z) ······················· Record CH.X - CH.Y and CH.Z to the specified area.

(CH.X)/(CH.Y) - (CH.Z) ······················· Record CH.X and CH.Y - CH.Z to the specified area.

Area specification (Type)

Reference

A channel not selected for any area will be skipped.

An error occurs when the same channel is set for multiple areas.

CH selection

Note