INST.No.INE-475-P1CE Software Version 1.00

-14-

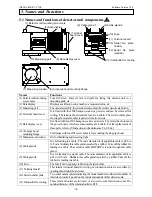

6.3.1-2) Functions of setting data

Data name

Function

(1)

Calibration curve

No.

An optional number from 1 to 99 can be designated as the calibration curve.

Ordinary It is designated sequentially from “1”.

(2)

Calculation mode Select the calculation mode the calibration curve The calculation mode and

wavelength number differs by the models of IRMA.

•

Calculation mode 1 to 3: The processing becomes the 2-wavelength

processing/3-wavelength processing (R1, S, R2)

on the each calculation mode.

•

Calculation mode 4: Multiple regression calculation that used each

wavelength. The wavelength number differs by the

models of IRMA.

Wavelength

λ

1

λ

2

λ

3

λ

4

λ

5

λ

6

λ

7

λ

8

λ

9

λ

10

Calculation group

Group 1

Group 2

Group 3

Calculation mode 1

R1 S R2

―

― ―

―

―

― ―

Calculation mode 2

―

― ―

R1 S R2

―

―

― ―

Calculation mode 3

―

― ― ―

― ―

R1 S R2

―

Calculation mode 4

λ

1

λ

2

λ

3

λ

4

λ

5

λ

6

λ

7

λ

8

λ

9

λ

10

(3)

Polynomial

coefficient

“a

0

to a

10

”

Polynomial coefficient is calculated by selected calculation mode.

•

Calculation mode 1 to 3: Assume that the calibration curve is represented by

the third-degree or lower-degree polynomial of

y = a

3

x

3

+ a

2

x

2

+ a

1

x + a

0

, where, “y” is the constituents and “x” is the

absorbance (“CH0” data of this detector unit).

•

Calculation mode 4: Calibration curve is calculated by multiple regression

calculation using each wavelength.

y = a

0

+ a

1

LOG(

λ

1) + a

2

LOG(

λ

2) +

····

+ a

10

LOG(

λ

10)

The wavelength number differs by the models of IRMA.

(4)

Correction

expression

coefficient

“b

0

to b

2

”

These coefficients are provided for the quadratic expression correction (zero and

span correction) with reference to the constituents “y”. Assuming that the

constituents after the correction be “Y”, we obtain “Y = b

2

y

2

+b

1

y + b

o

”.

(5)

Low/ High limit

constituents output

These specify constituents at a low limit output and a high limit output on the

analog output scaling. The output is scaled to 4mA at the low limit constituents

and 20mA at the high limit constituents.

(6)

Low/ High limit

constituents alarm

The low limit alarm is activated when the measured value is lower than the low

limit alarm set-point of constituents and the high limit alarm is activated when the

measured value is higher than the high limit alarm set-point of constituents. Use the

operator interface/display unit when the alarm outputs are required.

(7) Preset constituents

By turning on the preset output by key operations or through communications, the

constituents being set as a preset value is displayed and outputted, regardless of the

measured value.

(8) Water absorbance

Decide the water absorbance to compute the surface water ratio for measuring the

moisture content of sands, etc. [This setting is only enable when the surface water

ratio computation shown in (11) of “6.4.1 Setting data” is set to ON.]

The relation between the measured moisture content (%: mass basis moisture

content), the surface water ratio (%) and the water absorbance (%) is;

y

Surface water ratio = (Moisture content – Water absorbance) / (1 + (Water

absorbance / 100)

6. Operation