INST.No.INE-475-P1CE Software Version 1.00

-15-

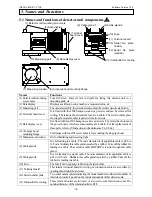

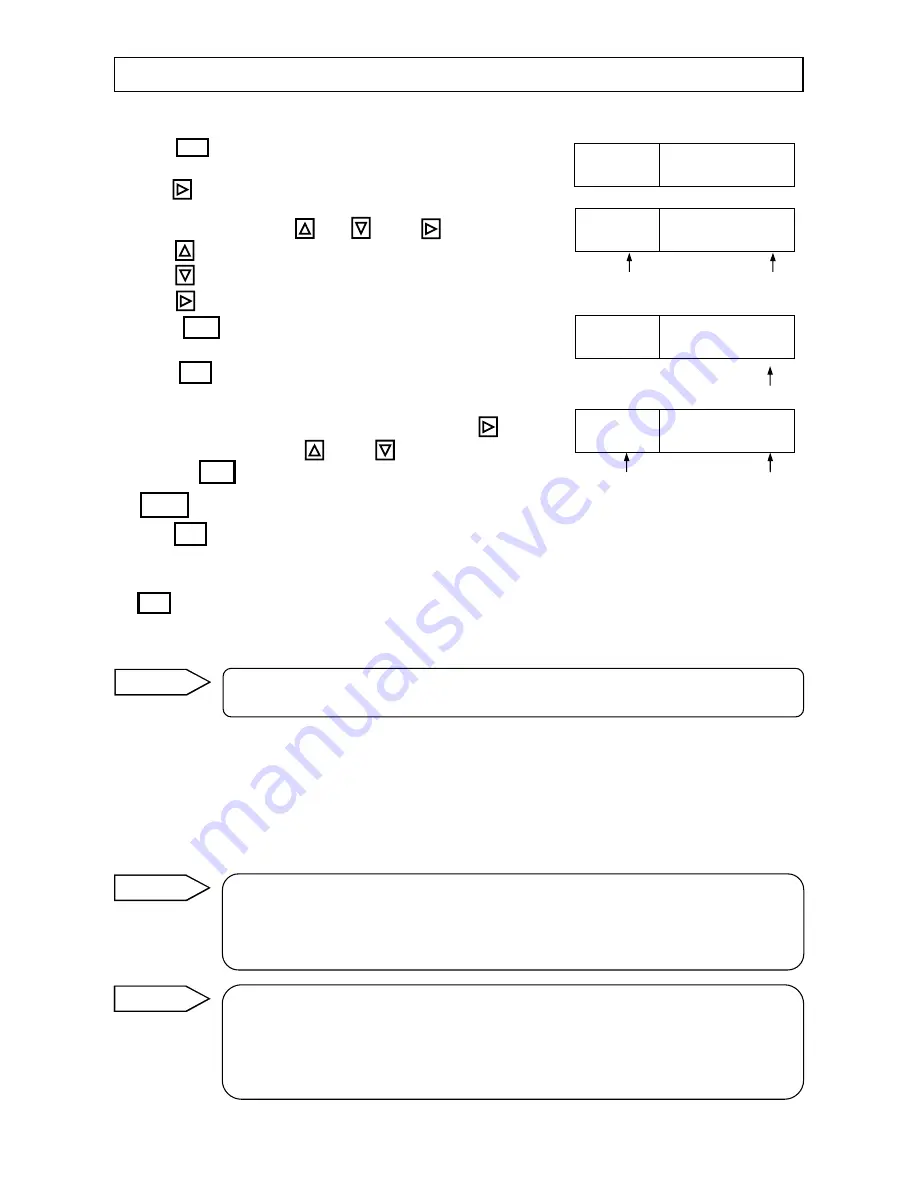

6.3.2 Procedure for setting

1) Press SEL key for 2 seconds to enter into the calibration

curve setting mode “CH”.

2) Press key. A numeric blinks for entering a calibration

curve number.

3) Change the numeric by key, key or key.

Press key to increase the numeric.

Press key to decrease the numeric.

Press key to shift the blinking digit.

4) Press ENT key. The numeric stops blinking and the

calibration curve number is stored.

5) Press SEL key to enter into the setting mode “A0” for

polynomial coefficient

a

0

.

6) Enter into a numeric setting mode by pressing key.

Change the numeric by key or key and store it by

pressing ENT key. For entering a decimal point, press

CH/

・

key at the blinking digit.

7) Press SEL key to enter into the next data setting mode.

8) Repeat the above procedure from 2) to 7) to set all data.

9) After the above setting procedure is completed, return to the measurement mode by pressing

SEL key for two seconds. The automatic return is made if no key is pressed for one minute.

6.3.3

Correcting calibration curves

If the actual constituents does not correspond with the constituents on the calibration curve being

preset due to the difference of one-line and off-line measurements, or other causes, correct it with

the correction coefficients b

0

, b

1

and b

2

in [6.3 Setting calibration curve data]. These coefficients

are provided for the quadratic expression correction against the measured value “y”. Assuming that

the measured value after correction be “Y”, we obtain,

Y = b

2

y

2

+ b

1

y + b

o

Usually, the shift correction is done with b

0

only. (b

1

= 1, b

2

= 0)

CH

DATA

C H

0

Setting data name

CH

DATA

A 0

0. 0 0 0 0

Setting data

Blinking

Calibration curve number

entering mode

CH

DATA

C H

0

CH

DATA

C H

3

Calibration curve number setting

The settings shown in the next paragraph can also be executed via the operator

interface/display unit (sold separately).

[Example 1: Moisture measuring]

When the measured moisture content before correction is 15 (%H

2

O) and the

actual moisture content is 13 (%H

2

O), “-2%H

2

O should be set.

(b

2

= 0, b

1

= 1, b

0

= -2)

6. Operation

R e m a r k s

R e m a r k s

[Example 2: Thickness and coating-thickness measuring]

When the measured thickness or coating-thickness content before correction is

25.0 (

µ

m) and the actual thickness and coating-thickness is 23.5(

µ

m ), “-1.5 (

µ

m)

should be set.

(b

2

= 0, b

1

= 1, b

0

= -1.5)

R e m a r k s