INST.No.INE-475-P1CE Software Version 1.00

-34-

9.1 Periodical inspection

The following inspections are required periodically.

(1) Cleaning the cover glass surface

Keep the cover glass surface of this detector unit clean all times. Wipe off dirt and flogging with

gauze or cloths like that.

It is more effective to impregnate the gauze with alcohol.

(2) Installation

Check this detector unit is correctly installed and fixed securely.

(3) Connections

Check the connections to all terminals of this detector unit, the operator interface/display unit, a

receiving instrument or other instruments are fixed securely.

(4) Purge air

Check flow, pressure and cleanness of air supplied for air-purging are adequate.

(5) Calibration

For maintaining the accuracy of this detector unit, the calibration of the unit once in 3 months is

recommended by using the output checker plate (Model IR-WEB or IR-WEB3: sold separately).

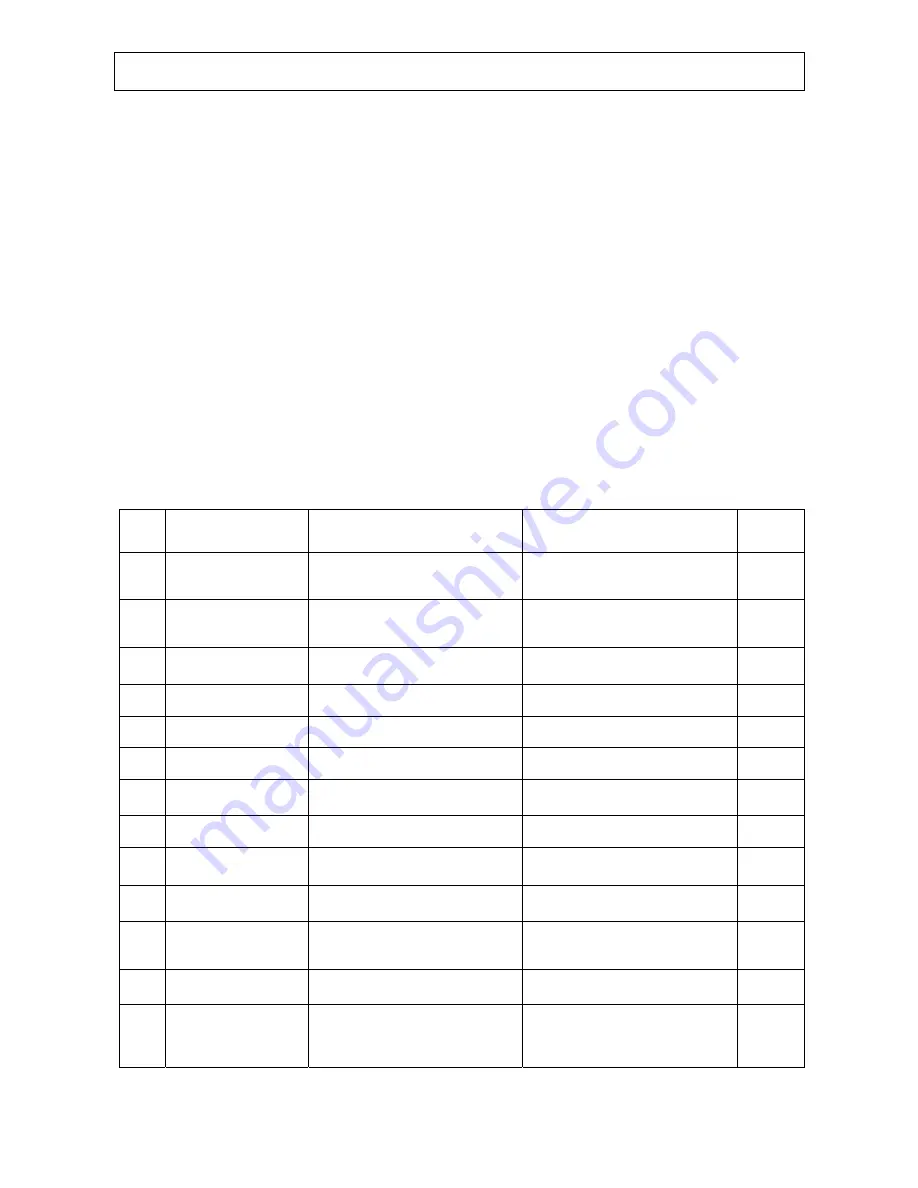

9.2 Self-diagnosis function

The self-diagnosis function is built in this detector unit. When an abnormal condition occurs, the

corresponding error number is displayed.

All error numbers are common to this detector unit and the operator interface/display unit.

Error

No.

Item Contents

Measures

Diagnosed

abnormal

condition*

-----

High limit over range Measured value is higher than

the displaying range.

Check the calibration curve data.

Check the output by the output

checker plate.

-----

Low limit over range Measured value is lower than the

displaying range.

Check the calibration curve data.

Check the output by the output

checker plate.

Er01 Nonvolatile

memory

abnormal

Writing to or reading from the

nonvolatile memory is disabled.

Return this

detector unit to

CHINO.

{

Er03 Motor

rotation

abnormal

The motor stops or rotates

abnormally.

Replace the motor.

{

Er06 Computation error

Overflow happed in computation Check the output by the output

checker plate.

{

Er07 Element temperature

abnormal

The element temperature is

abnormal.

Return this

detector unit to

CHINO.

{

Er12 Ambient

temperature

too high

The ambient temperature of the

detector unit is high

Lower the ambient temperature.

Er13 Ambient

temperature

too low

The ambient temperature of the

detector unit is low

Raise the ambient temperature.

Er14 Sample temperature

too high

The sample temperature is

higher than the correction range

Widen the correction range.

Er15 Sample temperature

too low

The sample temperature is lower

than the correction range

Widen the correction range.

Er16 Sample

low

reflection

The reflection rate of the sample

is low or the lamp is burned out.

Close the distance to the sample.

If the lamp is burned out, replace

it.

Er17 Sample

high

reflection

The reflection rate of the sample

is high.

Incline or extend the distance to the

sample.

Er20 Number of calibration

curves insufficient

for sample temperature

correction

The number of calibration

curves is insufficient for the

sample temperature correction..

Set two calibration curves setting

sample temperature or more.

9. Inspection and maintenance

(Note)

For the items filled with

{

in the self-diagnosed abnormal condition, a self-diagnosed abnormal

condition alarm is outputted from this detector unit and the operator interface/display unit.