9

2.1.1-

Safety

USA:

National Fuel Gas Code (NFGC) NFPA 54-2009/ANSI Z223.1-

2009 and the Installation Standards, Warm Air Heating and Air

Conditioning Systems ANSI/NFPA 90B

CANADA:

National Standard of Canada, Natural Gas and Propane

Installation Code (NSCNGPIC) CAN/CSA B149.1-2010

2.1.2-

General installation

USA:

NFGC and the NFPA 90B. For copies, contact the National Fire

Protection Association Inc., Battery march Park, Quincy, MA

02269; or for only the NFGC contact the American Gas

Association, 400 N. Capitol, N.W.,Washington DC 20001

CANADA:

NSCNGPIC. For a copy, contact Standard Sales, CSA

International, 178 Rexdale Boulevard, Etobicoke (Toronto),

Ontario, M9W 1R3, Canada

2.1.3-

Combustion and air ventilation

USA:

Section 9.3 of the NFPA54/ANSI Z223.1-2009 Air for

Combustion and Ventilation

CANADA:

Part 8 of the CAN/CSA B149.1-2010, Venting Systems and Air

Supply for Appliances

2.1.4-

Duct systems

USA and CANADA:

Air Conditioning Contractors Association

(ACCA) (Manual D), Sheet Metal and Air Conditioning

Contractors National Association (SMACNA), or American

Society of Heating, Refrigeration, and Air Conditioning

Engineers (ASHRAE).

2.1.5-

Acoustical lining and fibrous glass duct

USA and CANADA

: current edition of SMACNA, NFPA 90B as tested by

UL Standard 181 for Class I Rigid Air Ducts.

2.1.6-

Gas piping and pipe pressure testing

USA:

NFPA 54/ANSI Z223.1-2009 NFGC; Chapters 5, 6, 7, and 8

and national plumbing codes.

CANADA:

CAN/CSA-B149.1-2010, Parts 4, 5, 6, and 9.

IN THE STATE OF MASSACHUSETTS:

This product must be installed by a licensed plumber or gas fitter.

When flexible connectors are used, the maximum length shall not

exceed 36

”. (914 mm).

When lever type gas shutoffs are used they shall be "T" handle

type.

The use of copper tubing for gas piping is not approved by the state

of Massachusetts.

2.1.7-

Electrical connections

USA:

National Electrical Code (NEC) ANSI/NFPA 70-2011

CANADA:

CAN/CSA-B149.1-2010, Parts 4, 5, 6, and 9.

2.2- ELECTROSTATIC DISCHARGE

CAUTION

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in unit component damage.

Electrostatic discharge can affect electronic components. Take

precautions during furnace installation and servicing to protect the

furnace electronic control. Precautions will prevent electrostatic

discharges from personnel and hand tools which are held during the

procedure. These precautions will help to avoid exposing the control to

electrostatic discharge by putting the furnace, the control, and the

person at the same electrostatic potential.

1)

Disconnect all power to the furnace. Multiple disconnects may be

required. DO NOT TOUCH THE CONTROL OR ANY WIRE

CONNECTED TO THE CONTROL PRIOR TO DISCHARGING

YOUR BODY’S ELECTROSTATIC CHARGE TO GROUND.

2)

Firmly touch the clean, unpainted, metal surface of the furnace

chassis which is close to the control. Tools held in a person’s

hand during grounding will be satisfactorily discharged.

3)

After touching the chassis, you may proceed to service the

control or connecting wires as long as you do nothing to recharge

your body with static electricity (for example; DO NOT move or

shuffle your feet, do not touch ungrounded objects, etc.).

4)

If you touch ungrounded objects (and recharge your body with

static electricity), firmly touch a clean, unpainted metal surface of

the furnace again before touching control or wires.

5)

Use this procedure for installed and uninstalled (ungrounded)

furnaces.

6)

Before removing a new control from its container, discharge your

body’s electrostatic charge to ground to protect the control from

damage. If the control is to be installed in a furnace, follow items

1 through 4 before bringing the control or yourself in contact with

the furnace. Put all used and new controls into containers before

touching ungrounded objects.

7)

An ESD service kit (available from commercial sources) may

also be used to prevent ESD damage.

2.3- LOCATION

General

These furnaces are shipped with materials to assist in proper furnace

installation. These materials are shipped in the main blower compartment.

See Table 2 Loose parts list for loose parts bag contents. This furnace

must:

Be installed so the electrical components are protected from water;

Not be installed directly on any combustible material other than

wood flooring;

Be located close to the chimney or vent and attached to an air

distribution system. Refer to section 5 Ducts section;

Be provided ample space for servicing and cleaning. Always

comply with minimum fire protection clearances shown in Table 1

Minimum

clearance

to

combustible

material

for all units or on the furnace rating label.

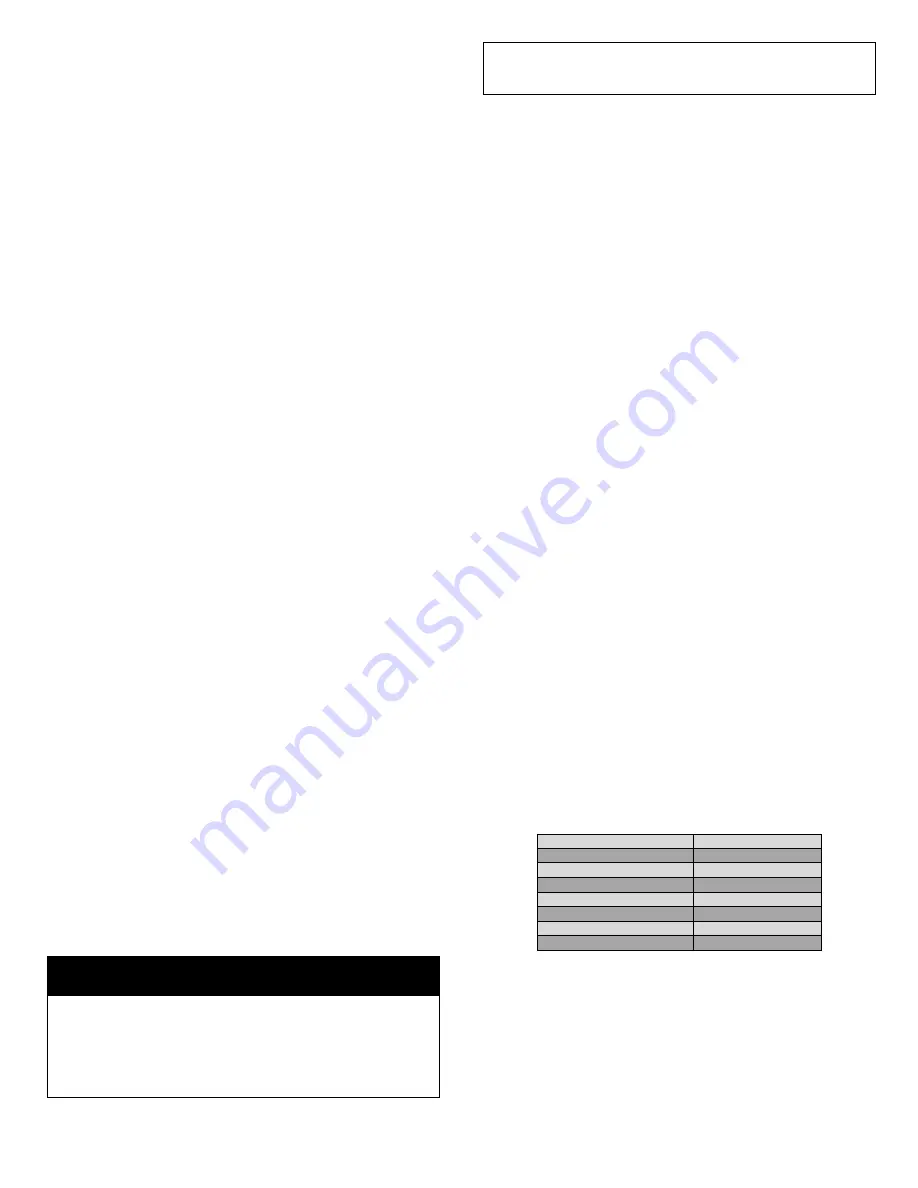

Table 1 Minimum clearance to combustible material

for all units

Position

Clearance in (mm)

Rear

0

Front

0

Required for service (front)

*24'' (610)

All sides of supply plenum

*1''(25)

Sides

0

Vent

0

Top of furnace

1''

*See local buildings codes.

Summary of Contents for c105-1-d

Page 20: ...20 Figure 16 Wiring diagram One stage PSC ...

Page 21: ...21 Figure 17 Two Stage PSC Furnace Control ...

Page 22: ...22 Figure 18 Two Stage ECM Furnace Control ...

Page 26: ...26 Figure 21 Direct venting Figure 22 Multi venting ...

Page 37: ...37 Figure 25 Part list 1 Stage PSC ...

Page 38: ...38 Figure 26 Part list 1 Stage PSC continued ...

Page 41: ...41 Figure 27 Part list 2 Stage PSC ...

Page 42: ...42 Figure 28 Part list 2 stage PCS continued ...

Page 45: ...45 Figure 29 Part list X13 ...

Page 46: ...46 Figure 30 Part list X13 continued ...

Page 49: ...49 Figure 31 Part list 2 Stage ECM ...

Page 50: ...50 Figure 32 Part list 2 Stage ECM continued ...