05

6

.

3

Wiring

requirements

The

capacitors

should

be

connected

by

stranded

soft

conductors

,

with

pressed

dedicate

copper

connecting

lug

.

See

Table

6

for

the

selection

of

conductor

sectional

area

.

Capacity

(

kvar

)

Minimum

installation

spacing

S1

(

mm

)

Safety

distance

at

the

top

of

capacitors

S2

(

mm

)

1

~

20

30

≥

50

22

~

32

50

≥

50

35

~

60

80

≥

50

Rated

voltage

(

kV

)

Rated

capacity

(

kvar

)

2

Conductor

sectional

area

(

mm

)

0

.

4

,

0

.

45

,

0

.

525

≤

10

4

.

0

0

.

4

,

0

.

45

,

0

.

525

12

~

20

6

.

0

0

.

4

,

0

.

45

,

0

.

525

24

~

32

10

.

0

0

.

4

,

0

.

45

,

0

.

525

35

~

60

16

.

0

or

25

.

0

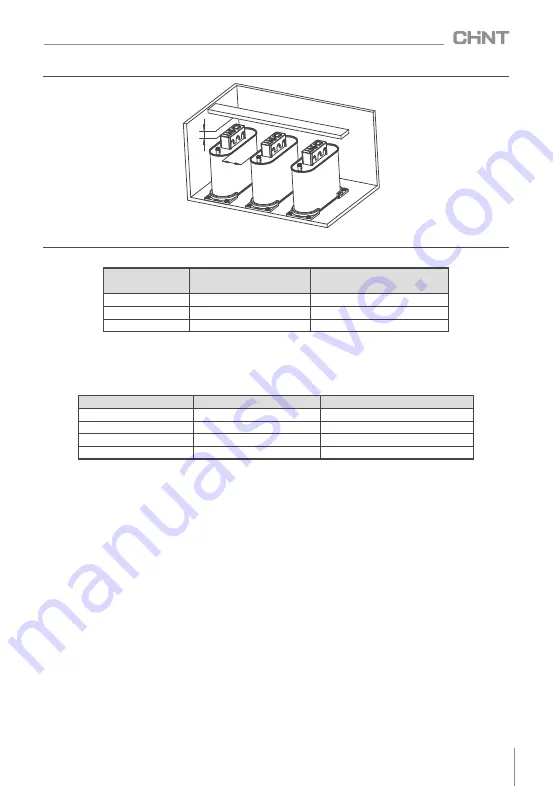

Figure

5

Capacitor

installation

drawing

Table

5

Safety

distance

6

.

4

Preparation

and

inspection

before

use

6

.

4

.

1

Before

using

the

capacitor

,

user

should

check

if

the

model

on

the

nameplate

is

consistent

with

that

of

the

product

.

User

should

also

check

if

the

included

accessories

are

complete

.

6

.

4

.

2

Capacitor

testing

:

Use

digital

capacitance

meter

to

test

the

capacitance

value

between

any

of

the

two

phases

of

the

3

-

phase

capacitor

,

the

result

should

not

be

smaller

than

half

of

the

rated

value

.

6

.

4

.

2

Before

using

the

capacitor

,

user

should

check

if

all

the

connections

are

secure

and

if

the

dust

guard

is

installed

,

make

sure

the

capacitor

is

reliably

grounded

.

6

.

5

Monitoring

and

recording

during

operation

6

.

5

.

1

User

should

check

the

operating

status

of

the

capacitors

on

a

regular

basis

,

check

if

the

3

-

phase

current

is

balanced

by

using

the

amperemeter

in

the

cabinet

.

6

.

5

.

2

If

the

3

-

phase

current

is

not

balanced

,

use

clamp

on

amperemeter

to

test

the

current

and

voltage

of

phase

A

,

phase

B

and

phase

C

of

each

group

of

capacitors

.

6

.

5

.

3

If

there

is

voltage

but

no

current

between

phases

,

it

means

the

overpressure

protector

is

disconnected

,

user

should

maintain

the

product

in

time

or

replace

it

if

necessary

.

6

.

5

.

4

Check

the

surface

temperature

of

capacitor

case

during

operation

,

if

the

temperature

of

any

individual

capacitor

case

exceeds

65

℃,

maintain

the

product

or

replace

it

if

necessary;

if

the

temperature

of

all

the

capacitor

cases

is

higher

than

65

℃,

take

effective

ventilation

and

heat

dissipation

measures

and

check

if

any

harmonic

source

device

(

such

as

frequency

converter

,

rectifier

and

inverter

,

and

medium

and

high

frequency

heating

furnace

)

is

used

at

user

load

end

.

6

.

6

Operation

procedure

,

method

and

precautions

for

shut

down

6

.

6

.

1

If

any

deformation

is

found

on

the

capacitor

case

,

there

is

oil

leakage

or

the

reactive

compensation

Table

6

Selection

of

conductor

sectional

area

S2

S1

BZMJ Series Self-healing Low Voltage Shunt Capacitors