NR8-200

、

NR8-630 Electronic Overload Relay

04

3.2

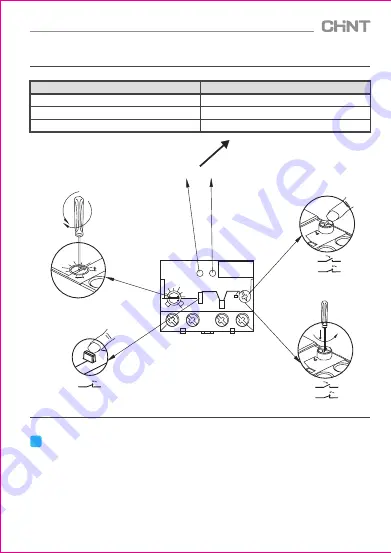

Operation and commissioning

Figure 4 Installation and commissioning diagram

100

120

140

160

180

200

Stop

NO

Test

Reset

NO

100

120

140

160

180

200

95

96 97

98

NC

NO

Stop

Test

Reset

Test functiom

96

98

95

97

Test

Reset

97

95

98

96

96

95

Manual reset

function

Continuously

adjustable current

range

Emergency stop function

G

reen light Red light

Indicator status

Circuit working status

Normal

Overload delay

Phase-failure delay

Green light flashing, red light off

Green light flashing, red light on

Green light on, red light flashing

4

Maintenance

Clean the dust on the electronic overload relay timely. Conduct product test and maintenance every

half a year to ensure the smooth operation of the product and the good contact of NO and NC contacts.

Tighten the terminal screws with specified torque and align the load protection capability of the electronic

overload relay according to commissioning requirements.

Please be careful when handling and installing the relay. It is prohibited to move the product by crane

so that the product will not be damaged and its protection characteristics will not be changed due to

strong impact.

Table 4 Indicator status