ChipBLASTER Inc

38

18.0. BELT INSTALLATION:

18.1. Align Sprockets:

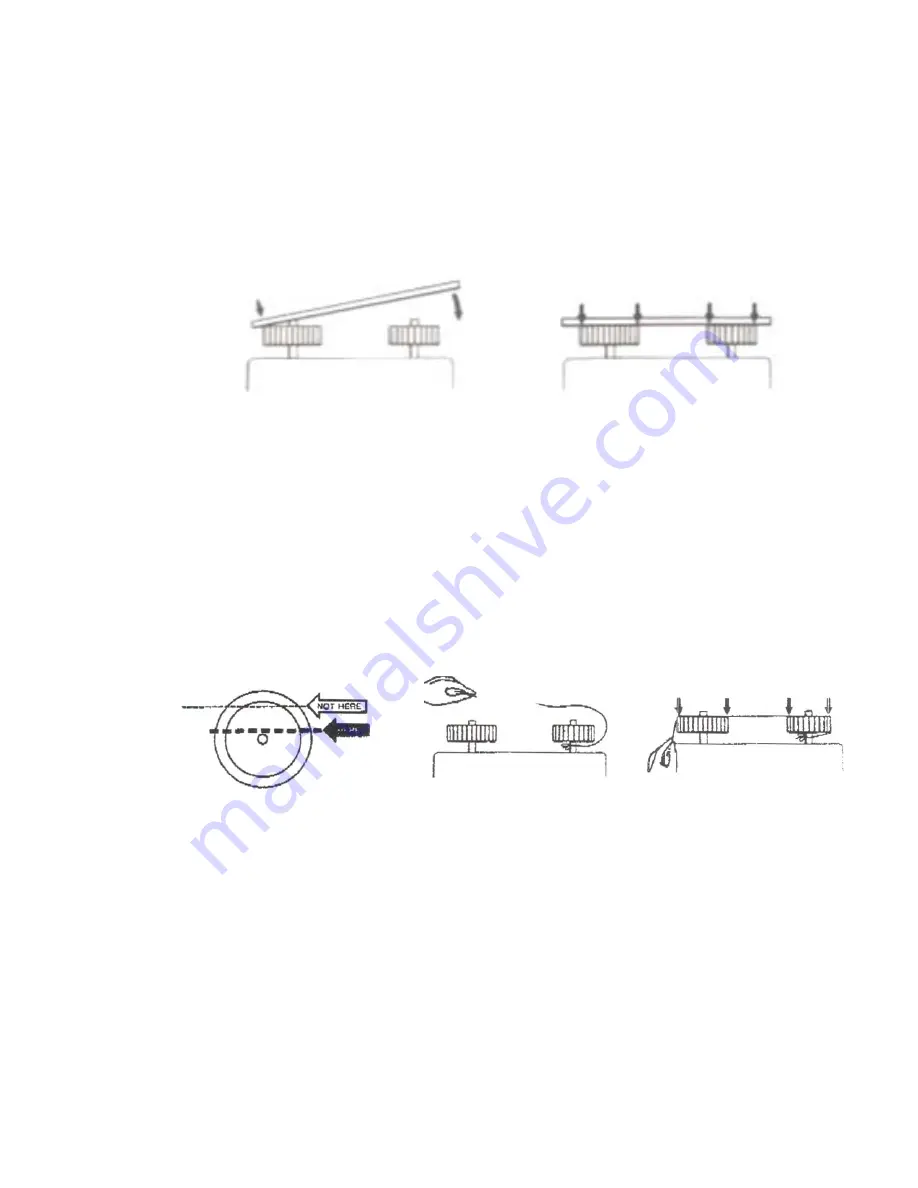

18.1.1. Sprocket alignment and parallelism of the shafts is very important. Proper

alignment helps to equalize the load across the entire belt width, thereby reducing

wear and extending belt life. The sketches below show how to align a

Synchronous drive properly. PLACE A STRAIGHTEDGE against the outside

edge of the sprockets as shown in Figure 11; Figure 12 shows the four points

where the straightedge should touch the sprockets.

Figure

11

Figure12

18.1.2. The straightedge should cross the sprockets at the widest possible part. (See

Figure 13.) OR USE A STRING. Tie a string around either shaft (Figure 14) and

pull it around and across the outer edge of both sprockets. Figure 15 shows how

the string should touch four points when the drive is properly aligned. After

aligning the sprockets, check the rigidity of the supporting framework. Shafts

should be well supported to prevent distortion and a resulting change in the center

distance under load. Do not use spring-loaded or weighted idlers. Idler sprockets

or pulleys must be locked into position after adjusting belt tension. Please note:

At least one sprocket must have a flange.

Figure

13

Figure

14

Figure

15

18.2. Install Belt:

18.2.1. Do not pry or otherwise force the belt onto the sprockets, as this can result in

permanent damage to the belt. Either remove the sprocket's outside flange or

reduce the center distance between the sprockets so that the belt can be easily

installed.

18.3. Belt Tensioning - General Method

18.3.1. This method of tensioning Synchronous belts should satisfy most drive

requirements.

18.3.1.1. Reduce the center distance so that the belt can be placed onto the

sprockets without forcing or prying it over the flanges.

18.0