ChipBLASTER Inc

80

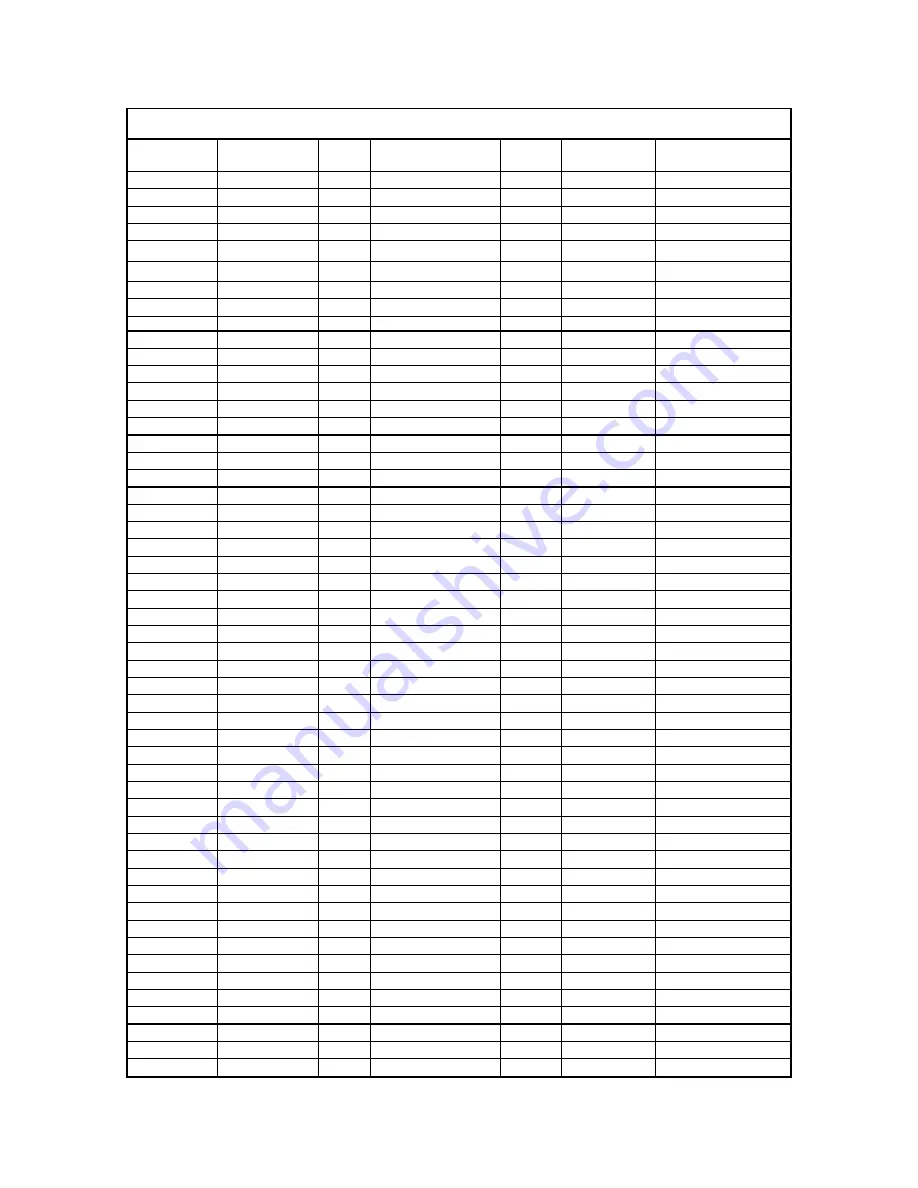

28.0. SUPPLEMENT DATA:

28.1. Orifice Reference Chart for 1000 PSI

Orifice Dia.

Outlet Area

(Sq. Inches)

PSI Velocity

(Ft./Sec.)

Volume

(GPM)

Horsepower

Required

Machine maximum

outputs

0.010 0.0001

1000 465

0.1 0.1

0.015 0.0002

1000 465

0.3 0.2

0.020 0.0003

1000 465

0.5 0.3

0.025 0.0005

1000 465

0.7 0.5

0.030 0.0007

1000 465

1.0 0.7

0.035 0.0010

1000 465

1.4 1.0

0.040 0.0013

1000 465

1.8 1.2

0.045 0.0016

1000 465

2.3 1.6

0.050 0.0020

1000 465

2.8 1.9

0.055 0.0024

1000 465

3.4 2.4

Nozzle #XX54

0.0024

1000

465

3.6

2.4

0.060 0.0028

1000 465

4.1 2.8

Nozzle #XX55

0.0028

1000

465

4.1

2.8

0.065 0.0033

1000 465

4.8 3.3

0.070 0.0038

1000 465

5.6 3.8

0.075 0.0044

1000 465

6.4 4.4

Nozzle #XX56

0.0049

1000

465

7.1

4.9

0.080 0.0050

1000 465

7.8 5.1

0.085 0.0057

1000 465

8.2 5.6

0.090 0.0064

1000 465

9.2 6.3

Nozzle #XX57

0.0069

1000

465

10.0

6.8

0.095 0.0071

1000 465 10.3 7.0

0.100 0.0079

1000 465 11.4 7.8

0.105 0.0087

1000 465 12.5 8.6

0.110 0.0095

1000 465 13.8 9.4

0.115 0.0104

1000 465 15.0

10.3

0.120 0.0113

1000 465 16.4

11.2

0.125 0.0123

1000 465 17.8

12.2

0.130 0.0133

1000 465 19.2

13.2

Nozzle #XX58

0.0138

1000

465

20.0

13.7

0.135 0.0143

1000 465 20.7

14.2

0.140 0.0154

1000 465 22.3

15.3

0.145 0.0165

1000 465 23.9

16.4

0.150 0.0177

1000 465 25.6

17.5

0.155 0.0189

1000 465 27.3

18.7

0.160 0.0201

1000 465 29.1

19.9

0.165 0.0214

1000 465 31.0

21.2

0.170 0.0227

1000 465 32.9

22.5

0.175 0.0241

1000 465 34.8

23.9

0.180 0.0254

1000 465 36.9

25.2

0.185 0.0269

1000 465 38.9

26.7

0.190 0.0284

1000 465 41.1

28.1

0.195 0.0299

1000 465 43.3

29.6

0.200 0.0314

1000 465 45.5

31.2

0.205 0.0330

1000 465 47.8

32.7

0.210 0.0346

1000 465 50.2

34.4

0.215 0.0363

1000 465 52.6

36.0

0.220 0.0380

1000 465 55.1

37.7

0.245 0.0471

1000 465 68.3

46.8

0.250 0.0491

1000 465 71.1

48.7

0.255 0.0511

1000 465 74.0

50.7

0.265 0.0552

1000 465 79.9

54.7

28.1