14

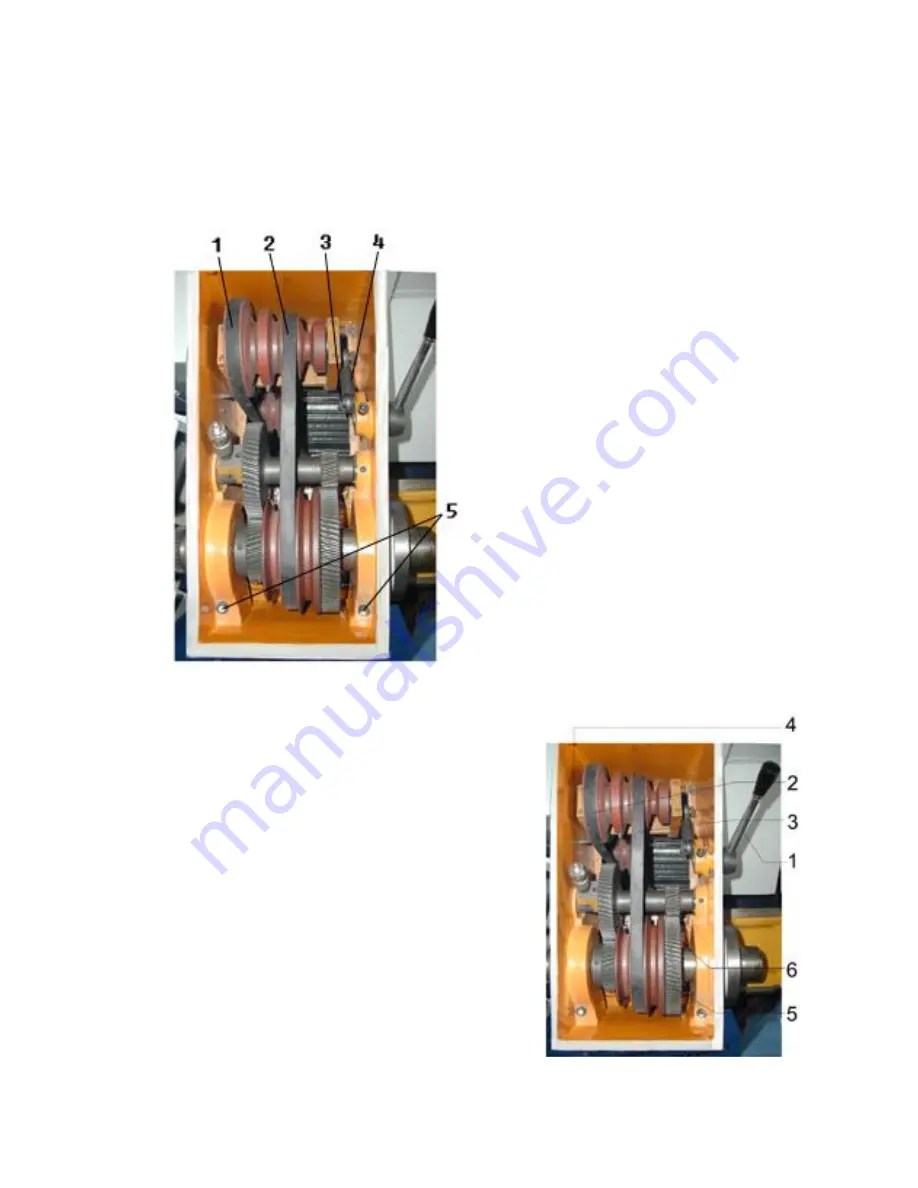

is loosen bolt (3) and turn out the screw rod (4) until the desired tension is set, then tighten the

hexagon bolt (3) in position.

The spindle and bearing are lubricated by the oil from two oil r eservoirs (5) which located

at each side of the headstock.

CAUTION: WHENEVER, THE SUFFICIENT OIL IN OIL RESERVOIRS MUST BE

MAINTAINED, IF NOT, PLEASE ADD OIL ACCORDING TO OIL GAUGE.

10.3 SPINDLE SPEED

There is gear and pulley system in the headstock.

Main spindle can obtain 12 kinds of speeds by

changing the position of belts or gears. In general

condition, light load and small diameter of

work-piece is suitable for high speed. The heavy load

and big diameter of work -piece for low speed.

CAUTION: DON’T CHANGE SPEED WHEN

THE SPINDLE IS RUNNING.

When change the spindle speed.

Please proceed as follows:

1) Move the control lever to middle position,

turn off the motor, make the spindle stop running.

2) Raise the headstock cover and pull the belt

tension lever (1) to the loose position.

3) Move the belt (2) (3) to the desired position as

the speed chart.

4) Push the belt tension lever back to the tightened position.

1

——

V

—

belt

2

——

V

—

belt

3

——

Bolt

4

——

Rod

5

——

Oil reservoirs

Summary of Contents for CZ1224

Page 7: ...6 5 GENERAL DIMENSIONS ...