24

3. Installation

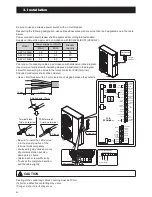

1. Isolate the mains power supply for the unit from the power source.

Do not connect the Remote controller cord with the power on.

2. Remove the wiring lid.

3. Connect the Remote controller cord to the PCB(Terminal), No.1-2 (Remote Controller). It does not matter which

wire of the Remote controller cord is connected to + and which to -. Take care not to let your screwdriver etc.

touch any of the other electronic parts. Do not use a power driver. It can damage the terminal screw holes.

4. If shielded wire is used, connect it to Terminal No.3(GND) on the PCB(Terminal).

5. Securely fasten the Remote controller cord with the cord fastening fitting. Leave the display board waterproofing

cover removed.

Master Remote controller

PCB(Terminal)

1 Remote controller

2 Remote controller

Master Remote controller

Shielded cable

Shielded cable

Shielded cable

Remote

Controller

1

2

3

GND

PCB(Terminal)

Remote

Controller

1

2

3

GND

Slave Remote controller

Master Remote controller

PCB(Terminal)

Remote

Controller

1

2

3

GND

Slave Remote controller

• The maximum length of the Remote controller cord is 100m.

Use shielded wire in case of the length with 30m or longer.

Connect the shielded wire to Terminal No.3(GND) on the PCB(Terminal).

2. Connecting with the equipment

Distance

Cable(mm

2

)

Shield

30m

MIN 0.5

non-shielded

30 100m

MIN 1.0

shielded

Summary of Contents for AEYC-0639U-CH

Page 156: ...20810030 M ...