Cone Assembly

48'' Belt Drive Cone Fan

12

MV1600B

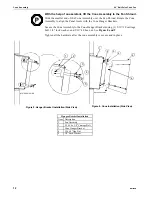

With the help of an assistant, lift the Cone Assembly to the Fan Shroud.

Slide the smaller end of the Cone Assembly over the Fan Shroud. Rotate the Cone

Assembly to align the Panel Joints with the Cone Hanger Brackets.

Secure the Cone Assembly to the Cone Hanger Brackets using (1) 5/16''-18 carriage

bolt, 3/8'' lock washer, and 5/16''-18 hex nut. See

Figure 8 and 9

.

Tighten all the hardware after the cone assembly is secure and in place.

MV1600-013 6/99

1

2

4

3

5

Hanger Bracket Installation

Item

Description

1

Fan Assembly

2

5/16-18 x 5/8'' Carriage Bolt

3

Cone Hanger Bracket

4

5/16-18'' Hex Nut

5

3/8'' Lock Washer

Figure 8. Hanger Bracket Installation (Side View)

MV1600-014 6/99

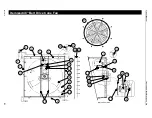

1

2

3

4

5

6

Figure 9. Cone Installation (Side View).