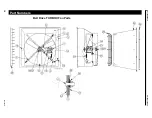

36" Be

lt Drive

Part Numbers

MV

16

80

K

17

Plastic Shutter Part Numbers

Item

Qty.

Description

Part No.

1*

1

Motor

Varies*

2

2

5/16-18x.75 SS Carr. Bolt

27868-1

3

1

Upper Motor Mount Support

37735

4**

1

36" Fiber Glass Fan Shroud

37913

36" Fiber Glass Fan Shroud (Black)

46970

5

1

Danger Decal

2527-50

6

1

36" Cast Aluminum Fan Blade

38902-1

7

1

Lower Motor Mount Support

37736

8

1

36" Fan Motor Mount

39785

9

1

Identification Decal

39002-XXX

10

1

AK-51 Sheave

42338

11

1

AX32 Gripnotch V-Belt

39783

12*

1

Sheave

Varies*

13

1

1" Shaft

39688

Item

Qty.

Description

Part No.

14

2

1" Cast Pillow Block Bearing

50553

15

2

1/4 x 1-1/8 Sq. Key

2419-2

16

2

Chore-Time Decal

2525-4

17

1

Self Tension Motor Mount

39677

18

1

Front Motor Mount Reinforcement Angle

39678

19

1

Rear Motor Mount Reinforcement Angle

39679

20

2

SS Self Tension BD Motor Mount Bushing

39681

21

1

SS Self Tension Motor Spring

39684

22

1

TURBO

®

Fan Motor Mount Brace

39710

23**

1

Outlet Cone (White)

38267

1

Outlet Cone (Black)

46971

24

1

Outlet Cone Grill

35228

25

1

Shroud Grill

37920

26

2

.375 x .875 x .075 SS Washer

8933

27

1

1/4-20x 7/8 SS Bolt

4404-17

28

1

Shutter Assembly

See “Fan Assembly Part Numbers” on page 14.

**Due to different color availabilities, Item Numbers vary depending on model of Fan.

MV1680-014 04/02

1

3

2

3

4

Item Description

Part No.

1

Shutter Assembly

(White) Plastic

38027

Shutter Assembly

(Gray) Plastic

46972

2

Push Nut, 1/4"

38032

3

Shutter Rod Pivot

38702-2

4

Shutter Louver (White) 38038-2

Shutter Louver (Gray) 46715-2

Figure 11.Plastic Shutter Part Numbers