SUPER-Selector

‘

PT Control

Page 4

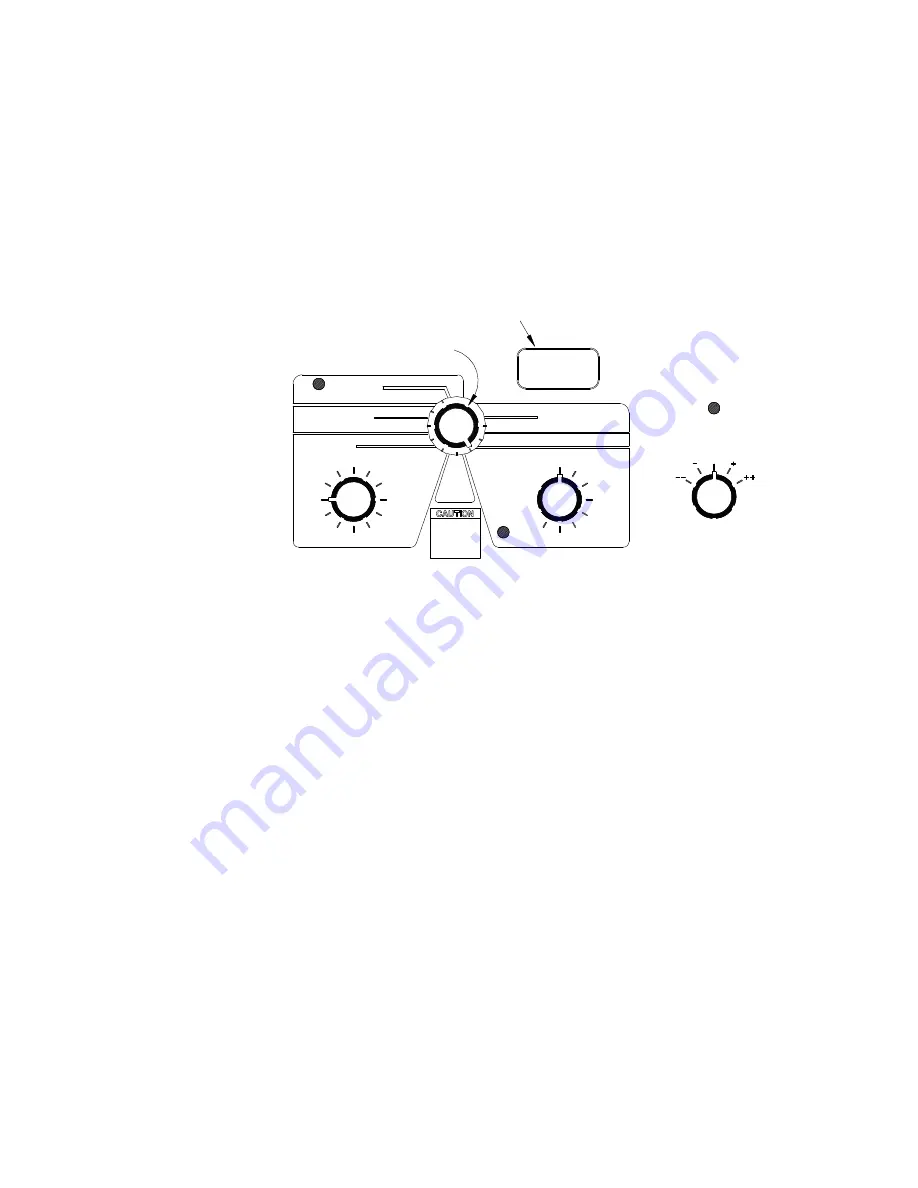

Programming the SUPER-Selector PT

The SUPER-Selector PT front panel is divided into different areas to clarify the

types of programming required. Each of the following must be properly set.

1. Setting stage temperatures, timers, and alarm limits.

2. Assigning the stage at which each output will be activated.

3. Assigning the stage that the control will go from power ventilation mode to tun-

nel ventilation mode.

Setting Stage Temperatures, etc.

The master selector determines what information is to appear in the display window.

The edit switch is used to change that setting. When the master selector is pointing

toward the stage setting switch or the sensor selector switch, those switches

determine what is shown in the display.

Stage #1 Timer

All outputs (except AUX-A and AUX-B) will time ON and OFF with the STAGE

#1 timer if the output knob is pointing towards 1. Above STAGE #1 the output will

be on steady as with a thermostat override.

The ON and OFF timers are in seconds and can be adjusted from 0 to 2000. The

appropriate amount of time to program depends on bird age, litter condition, and the

number of fans assigned to stage 1

Aux Stage #1 Timer

The AUX STAGE #1 TIMER applies to the AUX A and AUX B outputs. If an

AUX A or AUX B output is set on 1, it will turn on and off per the AUX STAGE #1

TIMER settings when the temperature is below stage #1, and on constantly for

temperatures at or above stage #1.

Outputs I and J are also affected by the AUX STAGE #1 TIMER in a different

manner intended for running cooling pads or foggers through a timer. For instance,

if Output I were set on 7, it would be off below stage #7 and ON and OFF per the

AUX STAGE #1 TIMER at or above STAGE #7.

The AUX STAGE #1 TIMER ON and OFF time can be set between 0 and 2000

seconds. If Output I and/or Output J are not to be timed, set the AUX TIMER OFF

TIME to 0 with the on time set to any number other than 0.

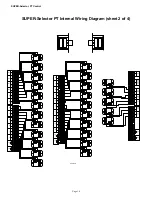

GREEN - NORMAL

0

SET

3

2

5

6

RED - EDIT

ON TIME

OFF TIME

ON TIME

OFF TIME

LOW ALARM TEMP

HIGH ALARM TEMP

READ SENSOR

8

FAILED

SENSOR

6

5

OFFSETS

TEMPERATURE

9

8

7

SET

POINT

TEMP

AUX

3

2

STAGES

H1

H2

1

ALARM

4

10

STAGE #1 TIMER

TIMER

1

7

CONTROL SENSOR

STAGE #1

4

DISPLAY WINDOW

MASTER SELECTOR

STAGE SETTING

SENSOR SELECTOR

EDIT SWITCH

MV1041-2 10/96

Set Point

Whenever

Backups

Is Changed

Reset